Open experiment device for teaching local resistance measurement during air flowing

An experimental device and air flow technology, applied in measuring devices, teaching models, measuring fluid pressure, etc., to reduce power, reduce local resistance, cultivate professional knowledge and scientific research and innovation capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

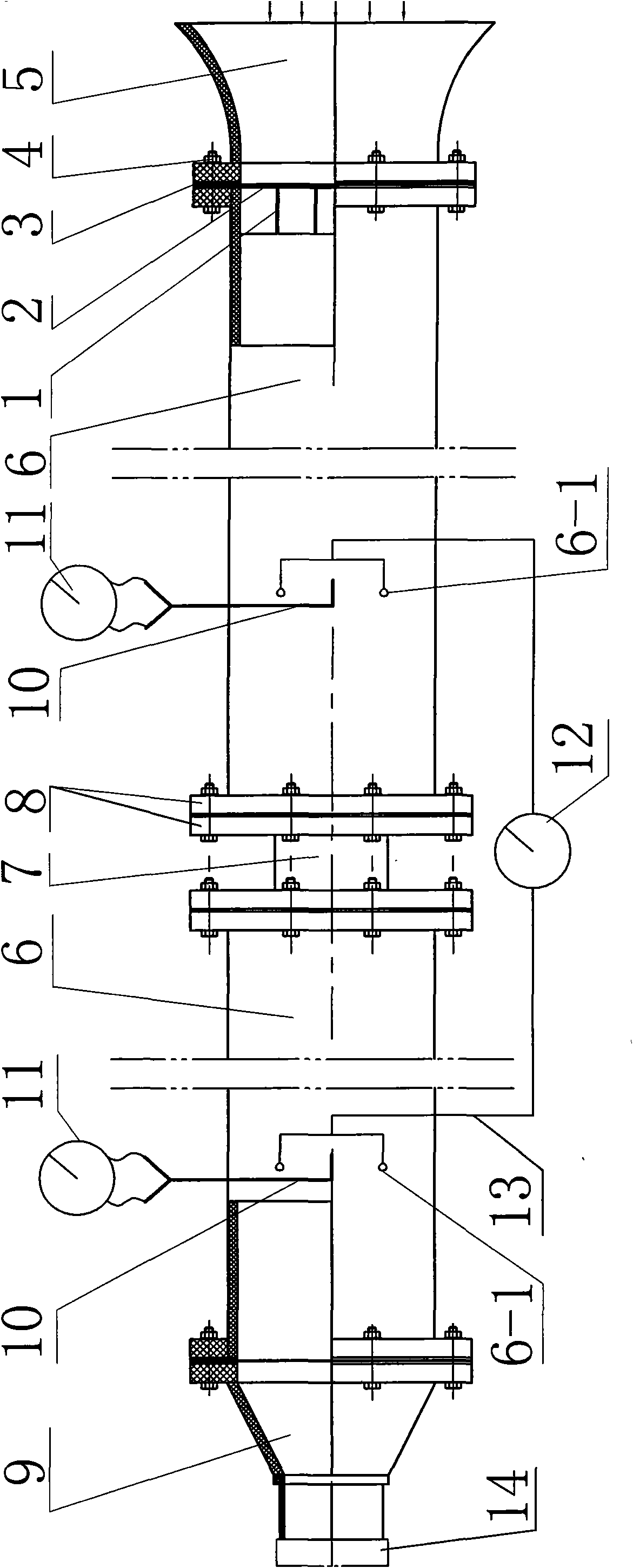

[0007] Specific implementation mode one: as Figure 1~3 As shown, an open air flow local resistance measurement teaching experiment device described in this embodiment includes a variable frequency speed regulation induced draft fan 14, a contraction section pipe 9, two measurement section pipes 6, an experimental section 7, an air inlet section pipe 5, Two Pitot tubes 10, two electronic micromanometers 11, two groups of pipelines 13 and an electronic micromanometer 12 for measuring differential pressure; the variable frequency speed regulation induced draft fan 14 communicates with the small end of the constriction pipe 9, The test section 7 is arranged between the two measuring section pipes 6 and is detachably communicated with respective one ends of the two, the large end of the constricting section pipe 9 communicates with the other end of one of the two measuring section pipes 6, and the two The other end of another in the measuring section pipe 6 communicates with an en...

specific Embodiment approach 2

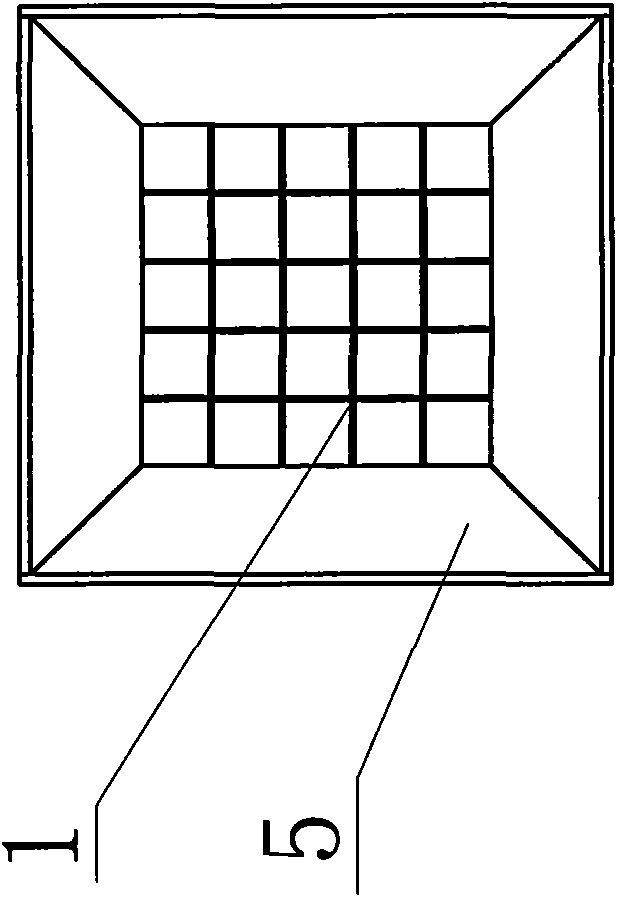

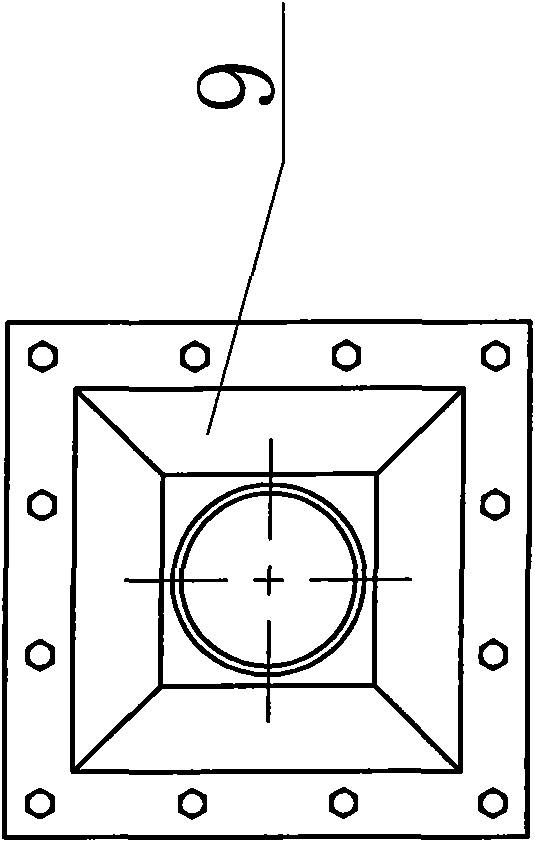

[0009] Specific implementation mode two: as Figure 4~6 As shown, the experimental section 7 in this embodiment is a cylinder with a square cross-section and tapered or a quadrangular cylinder with a shrinking cross-section. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: as Figure 7-8 As shown, the experimental section 7 in this embodiment is composed of two cylinders 7-2 with a square cross-section and tapered, and the small ends of the two cylinders 7-2 with a square cross-section and tapered connected together. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com