Wind-driven generator set, motor and air flow transfer device for motor air gap

A technology of airflow conveying and air gap, which is applied in the direction of wind power motor combination, wind power engine, electromechanical device, etc., and can solve problems such as unsatisfactory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

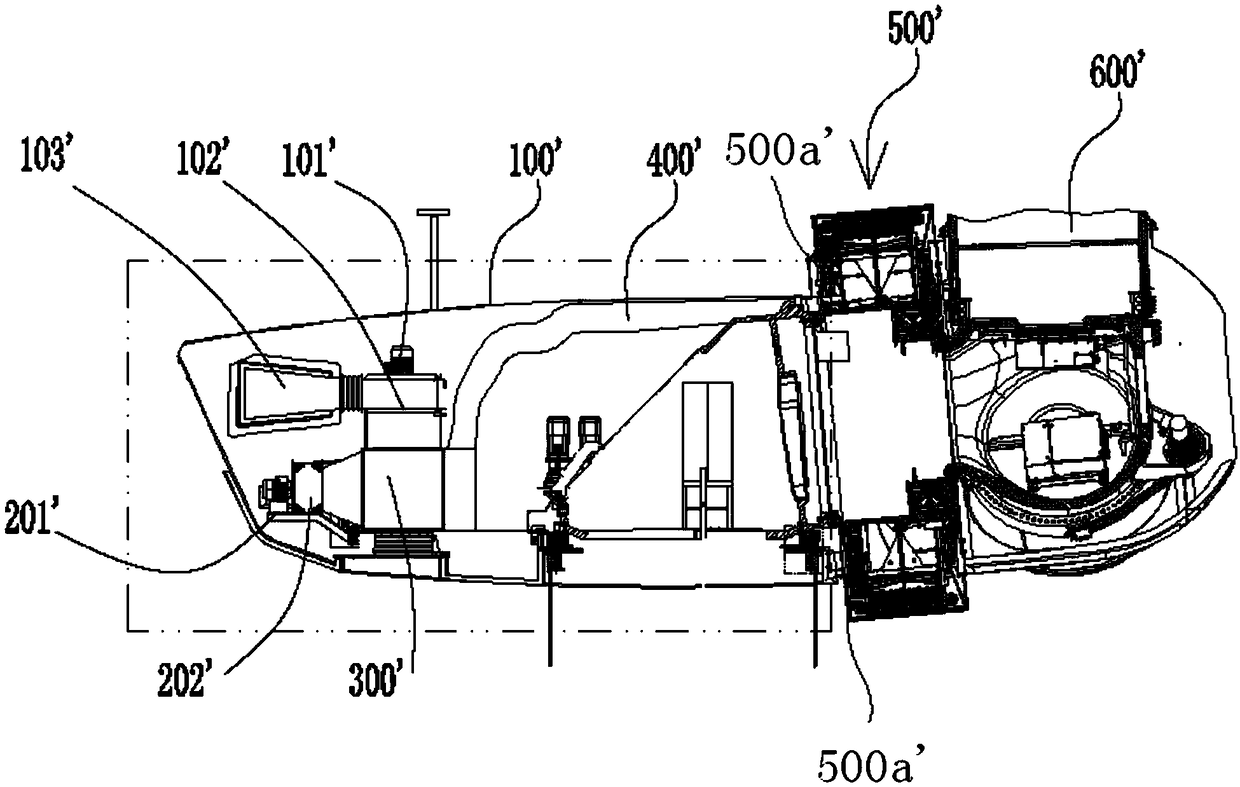

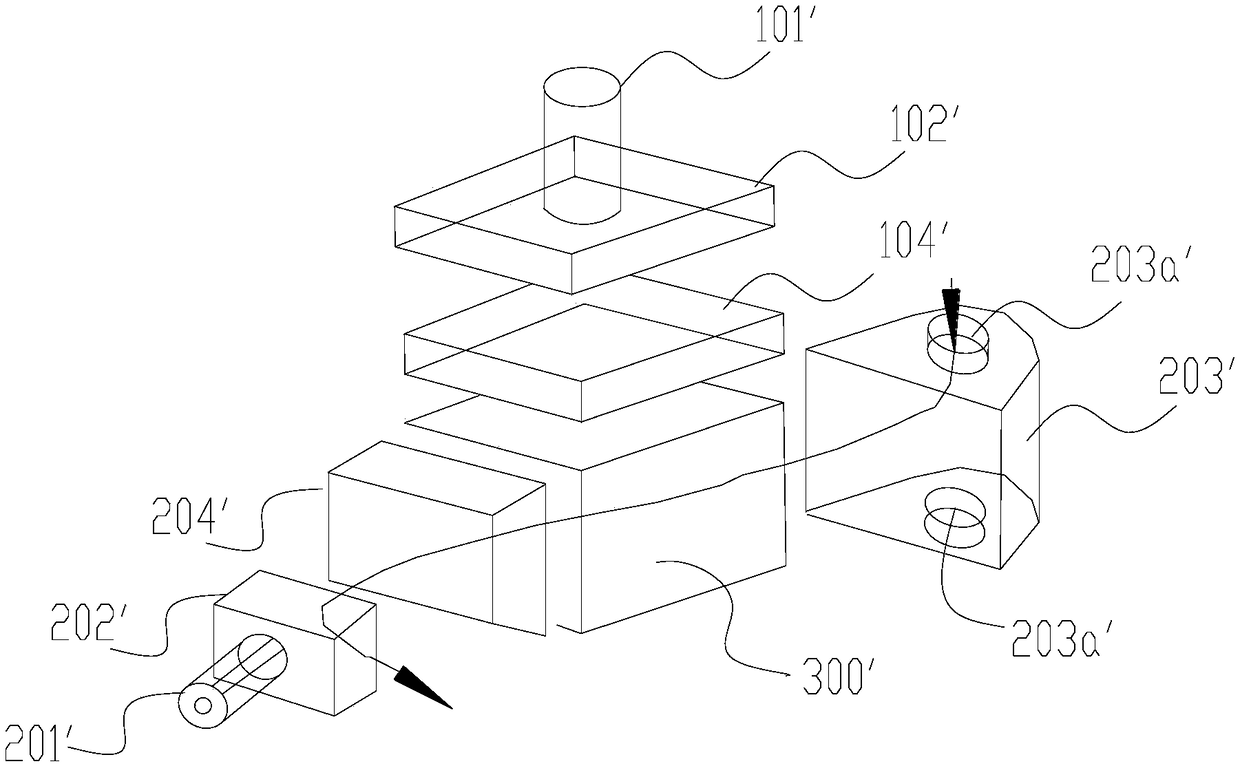

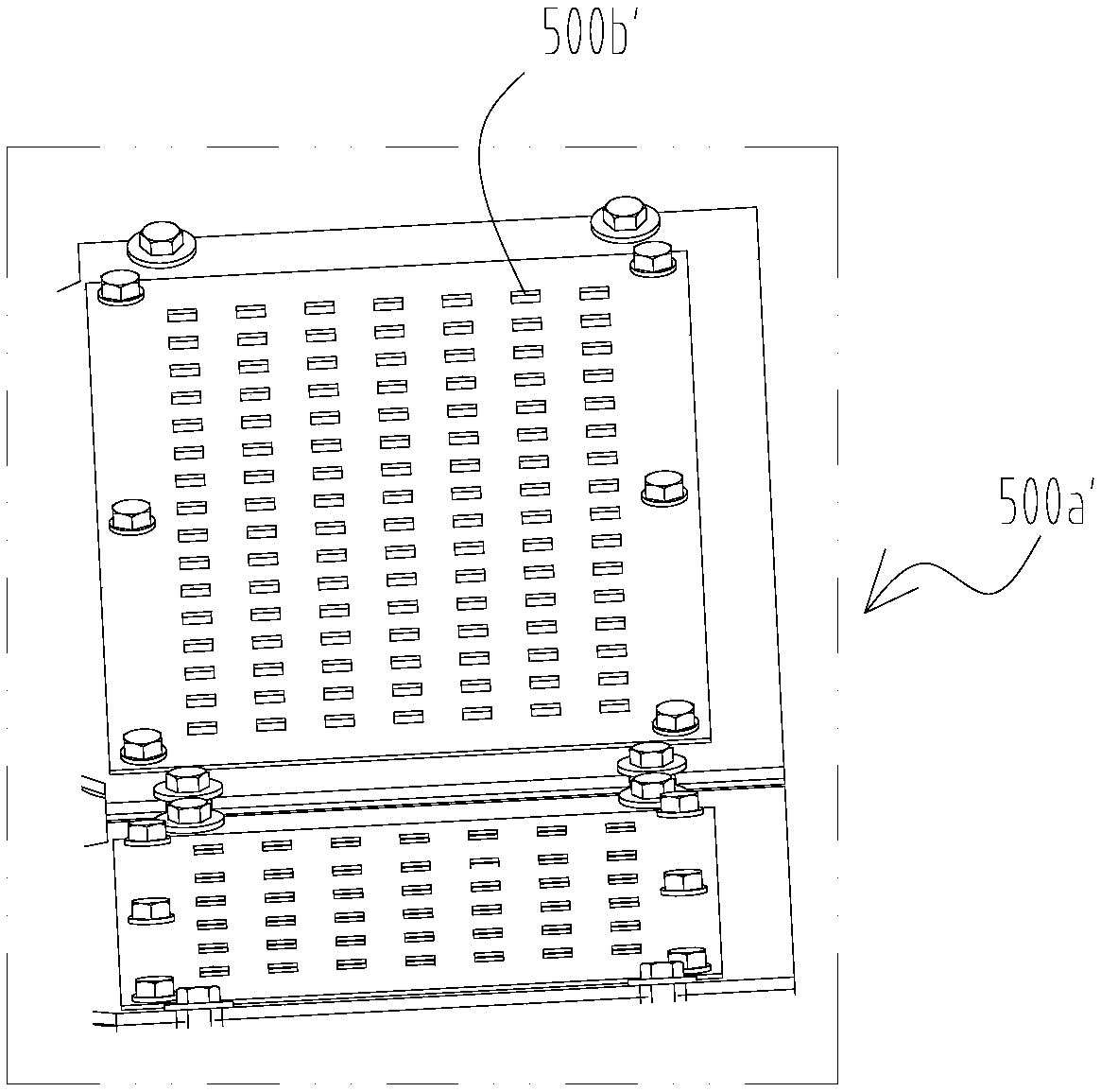

[0079] Please refer to Figure 4 , Figure 4 It is a structural schematic diagram of the first specific embodiment of the inner rotor permanent magnet pole motor provided by the present invention; Figure 5 for Figure 4 The schematic diagram of the motor in the middle; Image 6 for Figure 4 Partial enlarged view of part A in the middle; Figure 7 An end schematic view of an inner rotor permanent magnet pole motor.

[0080] The motor includes a rotor 20 and a stator 10 , the rotor 20 is an inner rotor structure, that is, the rotor 20 is located in the inner cavity of the stator 10 . The stator 10 includes an iron core 101 and a plurality of windings 102 wound on the iron core 101 . The rotating shaft 202 of the rotor 20 is inserted into the end cover of the motor through a bearing 203 . like Image 6 As mentioned above, there is an air gap a between the rotor 20 and the stator 10, and the air gap a extends along the axial direction of the motor, please combine Figure...

Embodiment 2

[0109] Please continue to refer Figure 12 , Figure 12 It is a structural schematic diagram of the second specific embodiment of the inner rotor permanent magnet pole motor provided by the present invention; Figure 13 for Figure 12 Partial enlarged view of part B in the center; Figure 14 for Figure 12 A partial view of the middle annular air distribution chamber 301 and the air gap a.

[0110] The motor structure of this embodiment is basically the same as that of Embodiment 1. The difference from Embodiment 1 is that Embodiment 2 does not provide an annular return chamber 302, but an annular air distribution chamber is provided at both air gap ports of the air gap a. 301. like Figure 12 As shown, the left end and the right end of the air gap a are provided with an annular air distribution chamber 301 . In this way, after the air flows through the annular air distribution chamber 301 and enters the air gap a, it all flows towards the middle of the air gap a. The ...

Embodiment 3

[0117] Please refer to Figure 16 , Figure 16 It is a structural schematic diagram of the third specific embodiment of the inner rotor permanent magnet pole motor provided by the present invention; Figure 17 for Figure 16 Partial enlarged view of part C in the middle; Figure 18 for Figure 16 A partial view of the middle annular air distribution chamber 301 , the air gap a, and the annular return chamber 302 .

[0118] This embodiment is basically the same as Embodiment 1, except that on the basis of Embodiment 1, the airflow conveying device further includes a vortex generator 311 to generate cold airflow or hot airflow and convey it to the air gap a. The principle of generating cold airflow and hot airflow by the vortex generator 311 will be described in detail below.

[0119] like Figure 19 , 20 as shown, Figure 19 for Figure 16 The basic structure of the medium vortex separator 311 and the working principle diagram of the total temperature separation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com