Flue-gas and air system and flow guide device, of flue-gas and air system, at cold secondary air inlet of air preheater

A technology of air preheater and flow guide device, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., which can solve the problems of increasing local resistance, too late to diffuse, uneven air distribution, etc., and achieve uniformity improvement , uniformity improvement, and the effect of improving the heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The core of the present invention is to provide a diversion device for the cold secondary air inlet of the air preheater, which can improve the uniformity of the airflow at the cold secondary air inlet of the air preheater, thereby improving the air The heat exchange effect of the preheater. Another core of the present invention is to provide a flue gas system including the air guiding device of the cold secondary air inlet of the air preheater.

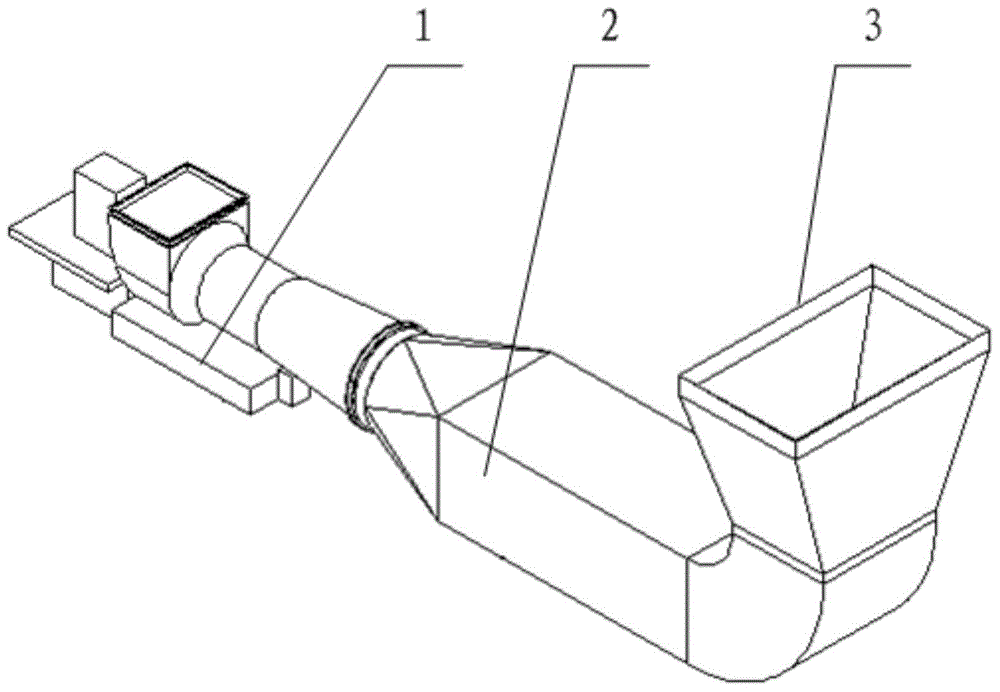

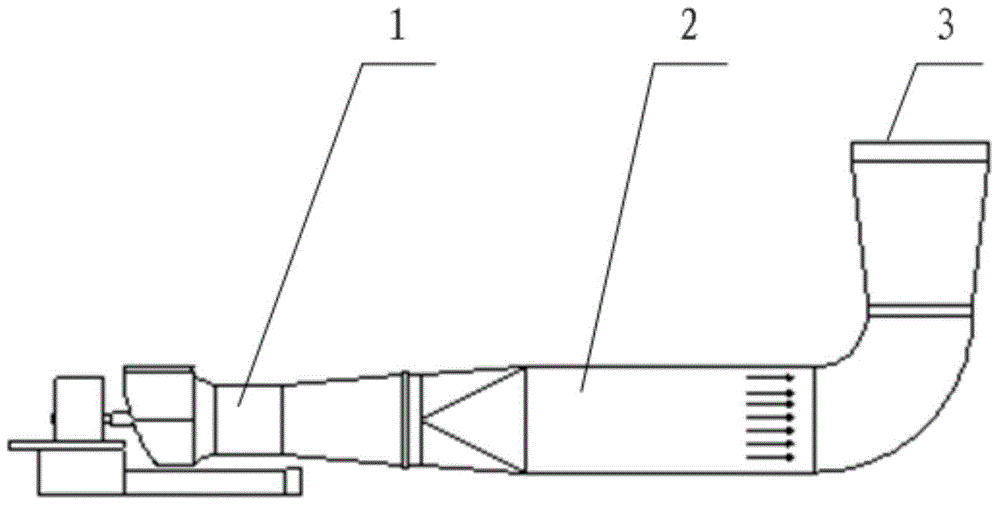

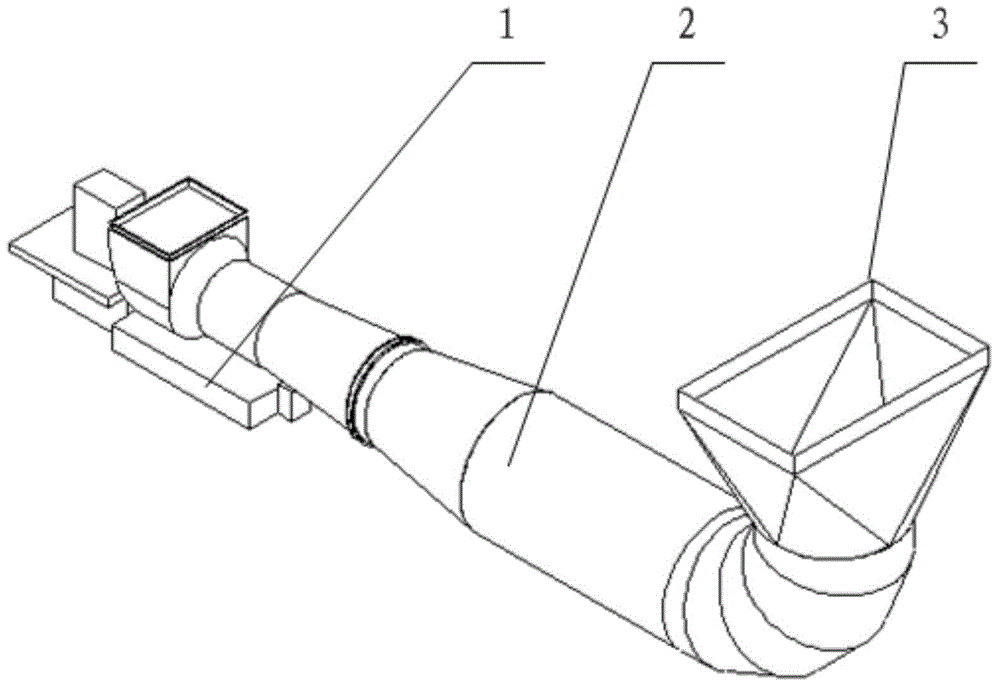

[0040] Such as Figure 5-Figure 8 As shown, Figure 5 It is a structural diagram of the air guide device of the cold secondary air inlet of the air preheater provided by the embodiment of the present invention when it is connected to the blower; Image 6 for Figure 5 Front view Figure 7 for Figure 5 Right view Figure 8 for Figure 5 Top view.

[0041] The air guide device for the cold secondary air inlet of the air preheater provided by the embodiment of the present invention includes a first connecting device 4 with a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com