Dry desulfurization absorbing tower with top circular winding pipe exit

A dry desulfurization and absorption tower technology, applied in the field of absorption towers, can solve the problems of large flue gas resistance at the outlet of the absorption tower, easy accumulation of solid particles, and large steel consumption, so as to reduce the accumulation of local solid particles and reduce flue gas Effect of local resistance and reduction of steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

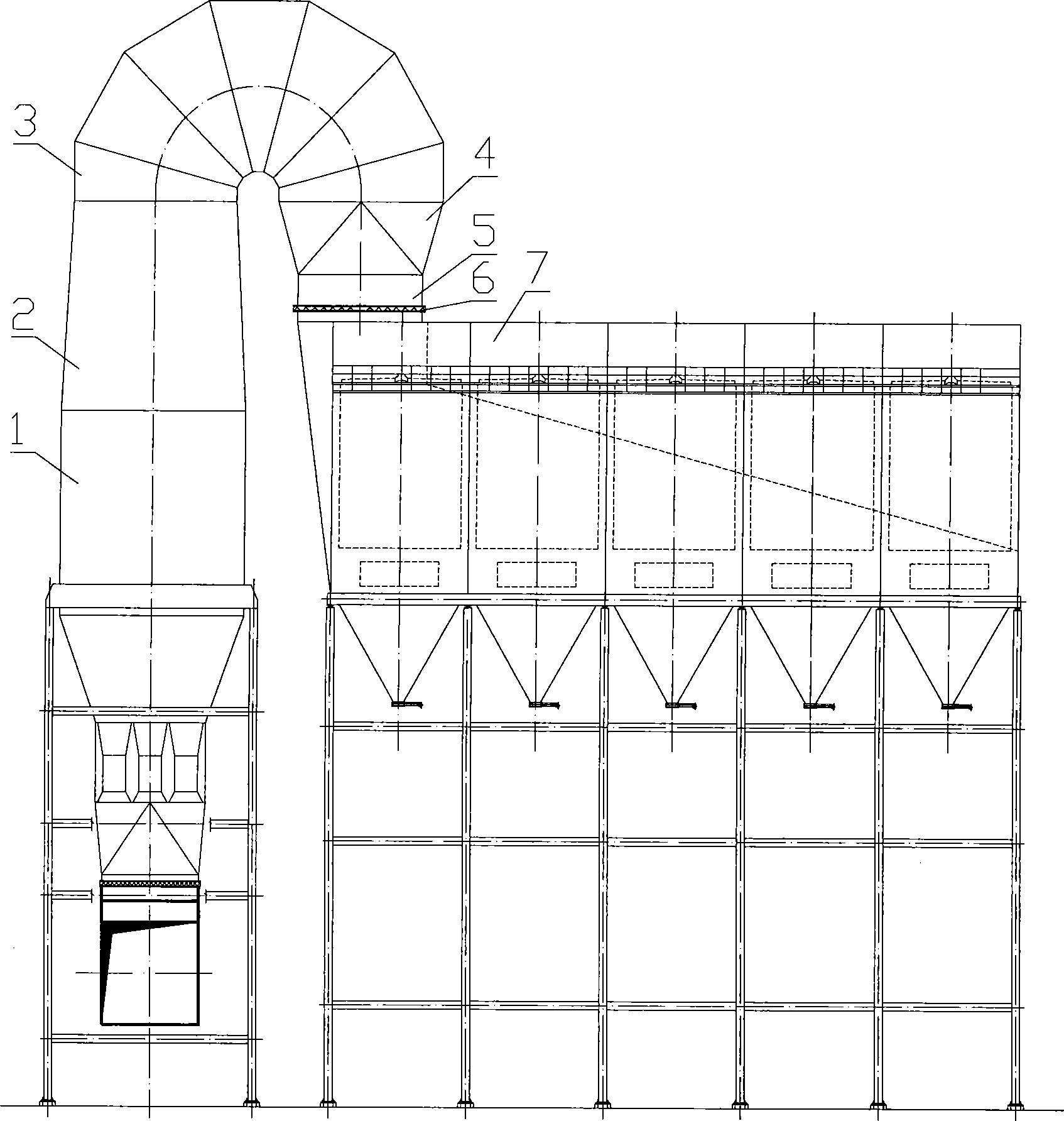

[0011] As shown in the accompanying drawings, a dry-process desulfurization absorption tower with a top circular elbow outlet of the present invention is connected with a variable diameter section 2 for adjusting the flow velocity at the top of the absorption tower main body section 1 (circular straight pipe section). An outlet flue 3 is installed above the diameter section 2, and the outlet flue 3 is in the shape of a 180-degree slow-rotating shrimp elbow, and is connected with the radius segment 4. An adjustment segment 5 is arranged below the radius segment 4, and the adjustment segment 5 is connected to the radius segment 4. The inlet connection of dust collector 7. The outlet flue 3 does not use a square flue but a circular flue. The circular flue has the advantages of good self-supporting force, large spacing between the required external reinforcement ribs, and small size, which can effectively reduce the steel material of the absorption tower outlet flue body. At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com