Winding method of nb3sn superconducting cable of large-size superconducting magnet

A technology of superconducting magnets and superconducting cables, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve problems such as irreversible performance degradation, achieve flexible and practical design, and ensure uniform distribution , good self-supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: A method for winding a niobium-tritin superconducting cable of a large superconducting magnet, comprising the following steps:

[0025] (1) According to the working conditions of the superconducting conductor, calculate the number of superconducting strands and copper wires required, and configure the composition of the superconducting cable to ensure that the superconducting strands and copper wires are evenly distributed inside the superconducting cable;

[0026] (2) The first-level twisted cable is made of three superconducting strands or a combination of superconducting wires and copper wires to form a first-level cable, which is molded and stabilized. The torque is selected to be 33 times the diameter of the first-level cable after molded;

[0027] (3) The second-level twisted cable is made of three to four first-level cables to form a second-level cable. The same first-level cable can be used, or a mix of different components of the first-level cable c...

Embodiment 2

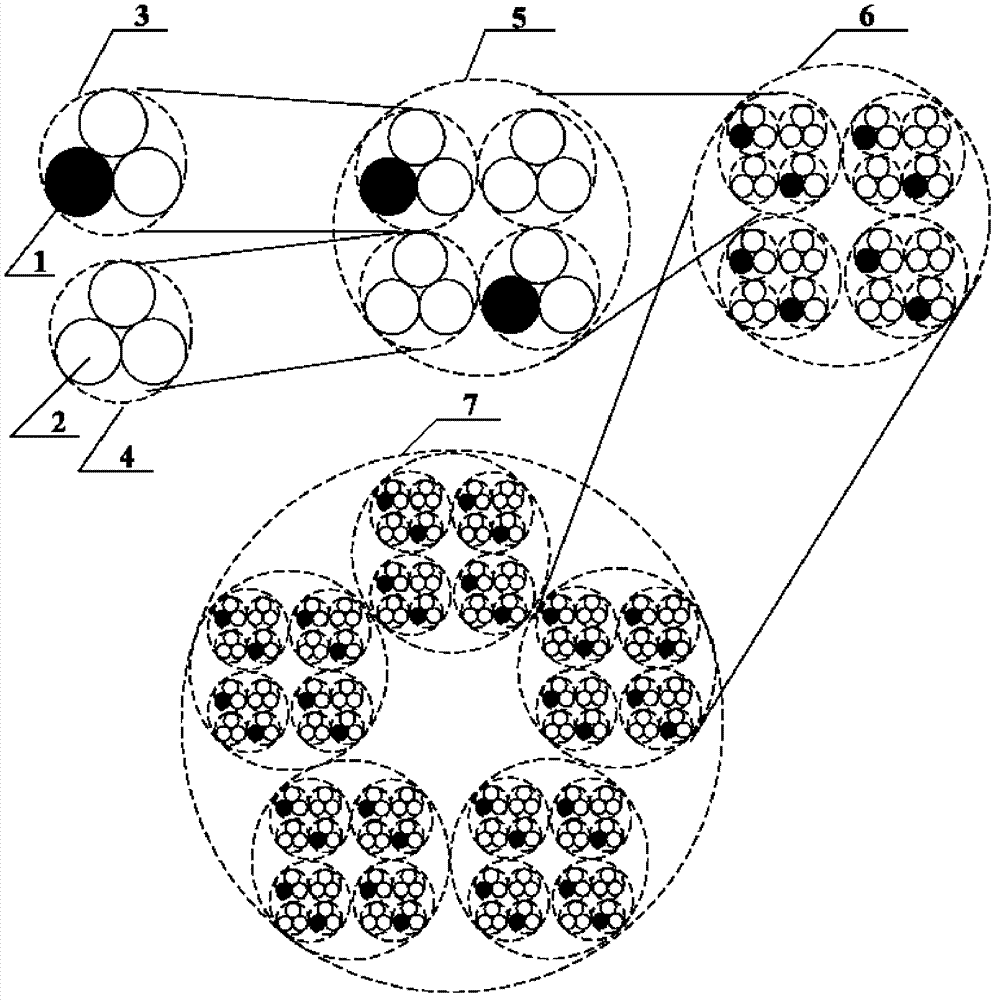

[0031] Example 2: Such as figure 1 As shown, the winding method of the niobium-three-tin superconducting cable of the large-scale superconducting magnet includes the following steps: the superconducting cable is wound by four-level cable twisting, and the copper wire 1 and the superconducting wire 2 are combined. Twisted to form the first class one cable 3, three superconducting wires 2 are stranded to form the second class one cable 4; four two kinds of different class one cables are mixed and matched to form a class two cable 5; Grade 5 cables are twisted into grade 3 cables 6; five grade 3 cables 6 are twisted into grade 4 cables 7, overmolded and reduced in diameter, and 50% of the surface is wrapped with 0.05mm thick 316L stainless steel strips to make a Niobium tritin superconducting cable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com