Method for preparing all-solid-state polymer electrolyte through in-situ thermal initiation and application

An all-solid polymer, thermally induced technology, applied in solid electrolytes, non-aqueous electrolytes, non-aqueous electrolyte batteries, etc., can solve the problem that it is not suitable for direct in-situ preparation of polymer batteries, and improve the preparation cost and grafting rate of polymer electrolytes. Inability to precisely control problems such as reducing interface wetting and modification, improving interface compatibility and wide salt selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

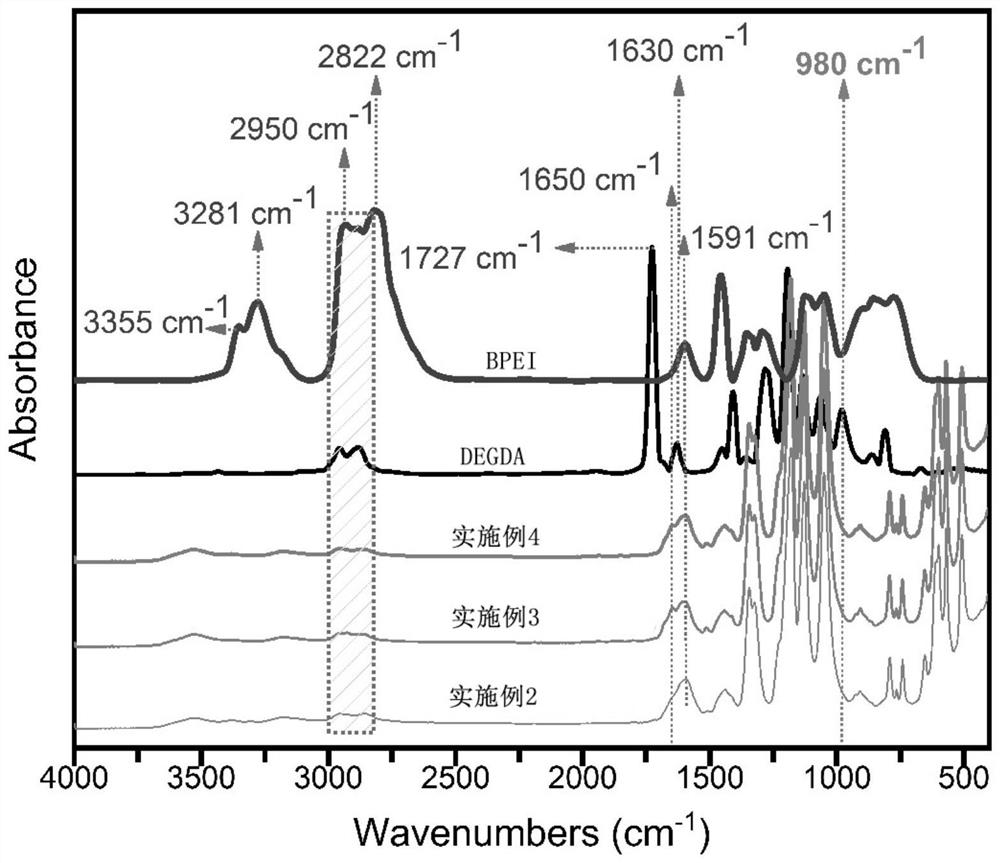

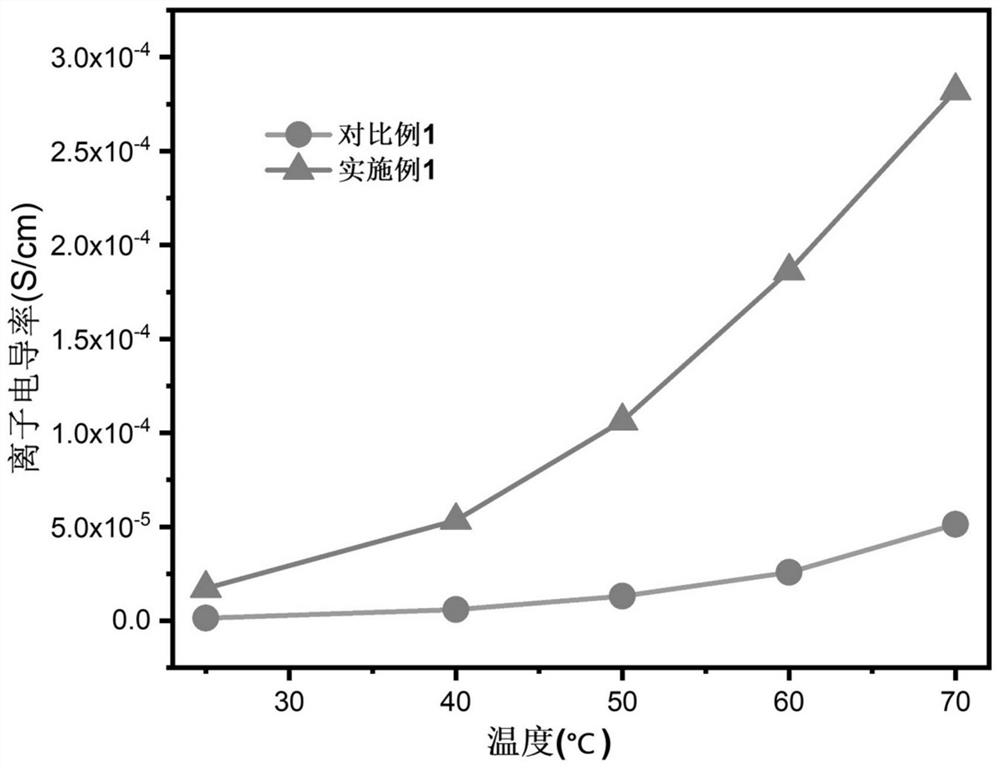

Embodiment 1

[0028] Components and parts by weight thereof in the mixed solution are as follows:

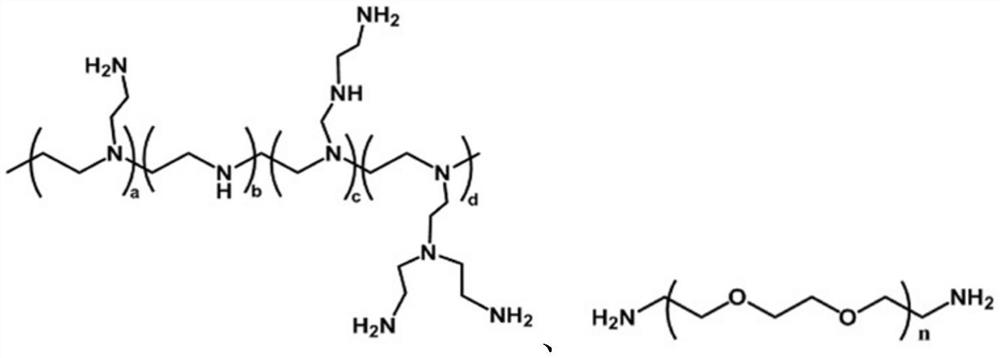

[0029] Branched Polyethyleneimine (BPEI) 40

[0030] Diethylene glycol diacrylate (DEGDA) 20

[0031] LiTFSI 20

[0032] Methanol 20

[0033] The in-situ reaction temperature is 60° C., and the reaction time is 1 h.

Embodiment 2

[0035] Components and parts by weight thereof in the mixed solution are as follows:

[0036]

[0037] The in-situ reaction temperature is 25°C, and the reaction time is 8h.

Embodiment 3

[0039] Components and parts by weight thereof in the mixed solution are as follows:

[0040]

[0041] The in-situ reaction temperature is 40°C, and the reaction time is 3.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com