Insulating brick

A technology for thermal insulation bricks and brick bodies, which is applied to building materials and other directions, can solve the problems of unfavorable thermal insulation effect, reduced thermal insulation performance, and high damage rate of thermal insulation bricks, and achieves good thermal insulation effect, good self-supporting force, and structural integrity. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

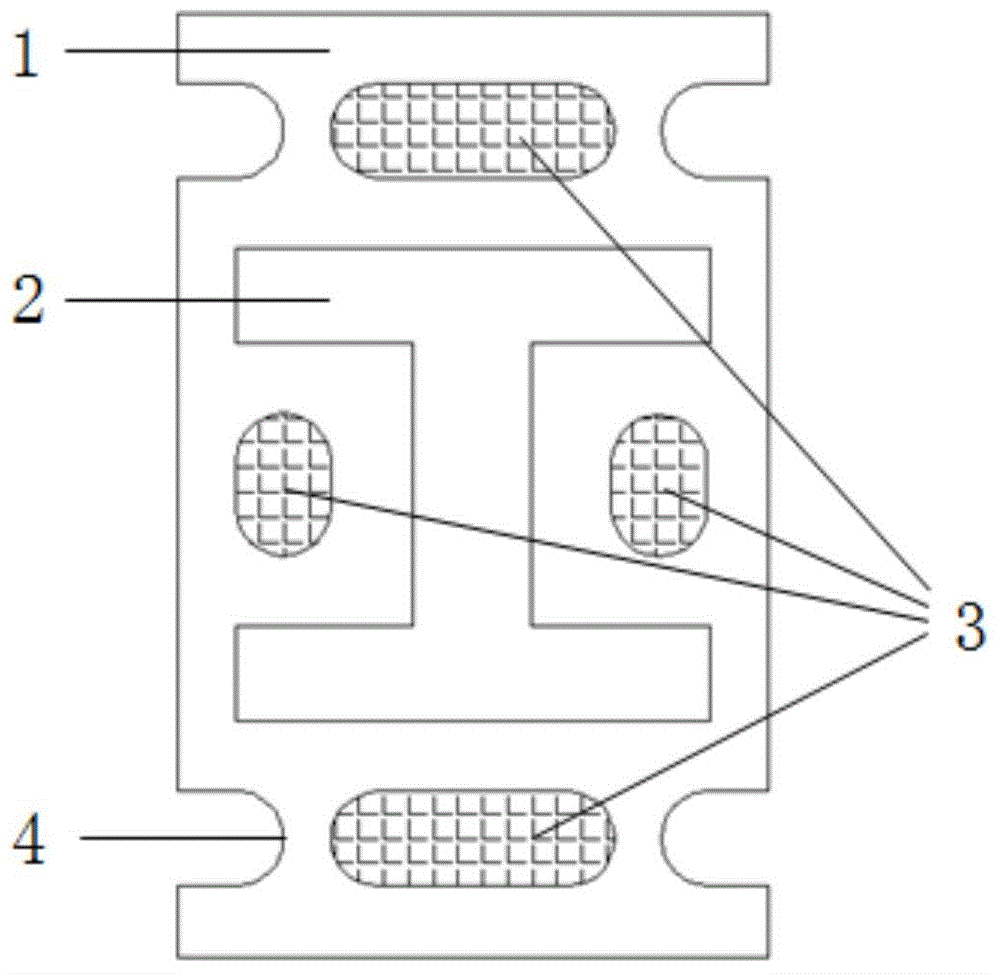

[0012] Such as figure 1 As shown, a light-duty thermal insulation brick includes a thermal insulation brick body 1, and an "I" type through hole 2 is arranged in the thermal insulation brick body, which is located in the middle of the brick body, and the four directions of the through hole 2 are up, down, left and right. All are provided with filling holes 3, the sections of the filling holes 3 are all rectangular, and the four chamfers of the rectangles are all round, and polystyrene foam is filled in the filling holes, and the upper and lower filling holes are filled with Grooves 4 are arranged on both sides of the brick body with the holes at the same horizontal position. The cross-section of the groove 4 is rectangular, and the two chamfers of the rectangle are circular.

[0013] An embodiment of the present invention has been described in detail above, but the content described is only a preferred embodiment of the present invention, and cannot be considered as limiting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com