High-capacity quartz combustion tube for oil product analysis

A high-capacity, combustion tube technology, used in chemical analysis by combustion, preparation of samples for testing, etc., can solve the problems of incomplete combustion, small injection volume, troublesome, etc., and achieve the effect of prolonging the combustion time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

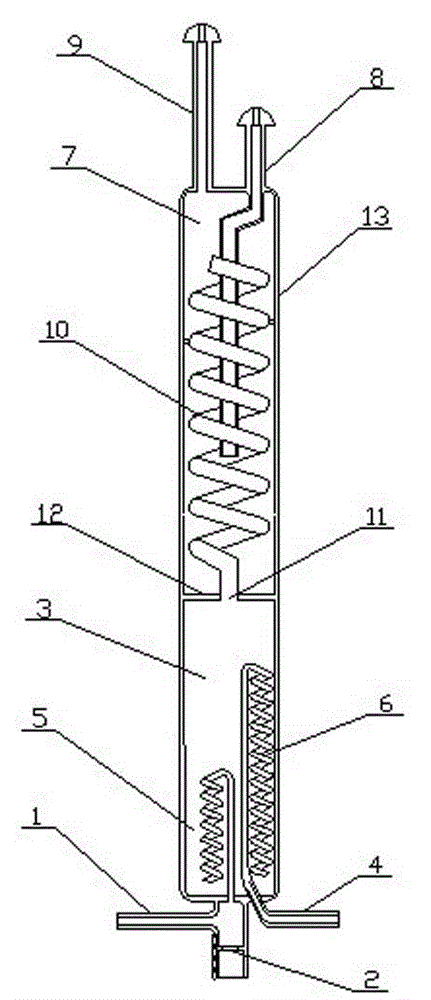

[0014] see figure 1 , the carrier gas inlet 1 at the inlet end of the combustion tube body 13 is connected to the inner end of the injection port 2. The carrier gas is generally high-purity argon or high-purity nitrogen, and the flow rate of the carrier gas is adjusted to 100-150 ml / min. Seal with a silicone gasket. After taking an appropriate amount of sample with a micro-syringe, it is inserted into the sample inlet 2 through a silica gel pad. Under the carrier gas, the sample is preheated in the helical carrier gas preheating tube 5 and then enters the first combustion chamber 3; The inlet 4 and the spiral oxygen preheating pipe 6 enter the first combustion chamber, adjust the oxygen flow to 150-300 ml / min, the oxygen can be preheated to a certain temperature, and the outlet ends of the two preheating pipes are close to the pipe body At the inlet end, the sample can meet the preheated oxygen as soon as it leaves the carrier gas preheating tube 5, and a combustion reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com