A combustion chamber spanning support plate

A combustion chamber and support plate technology, applied in the combustion chamber, continuous combustion chamber, combustion method and other directions, can solve the problems of large resistance and reduce the propulsion efficiency of the engine, so as to improve the temperature, improve the fuel mixing efficiency, and reduce the total pressure loss of the airflow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

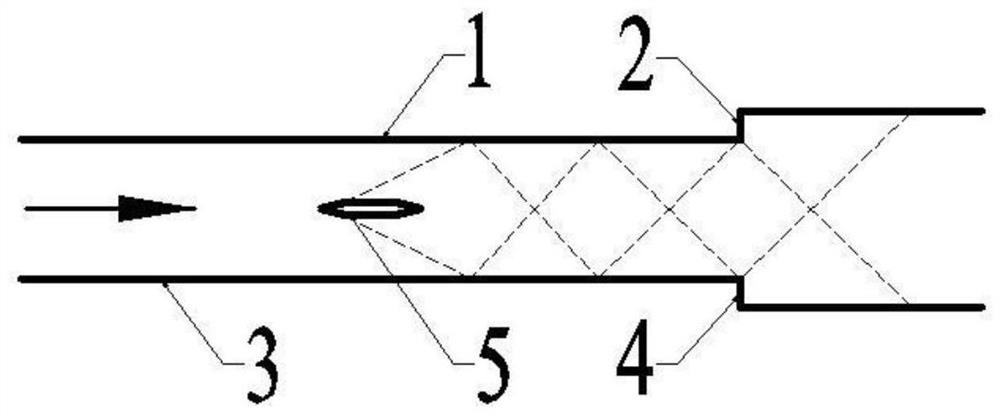

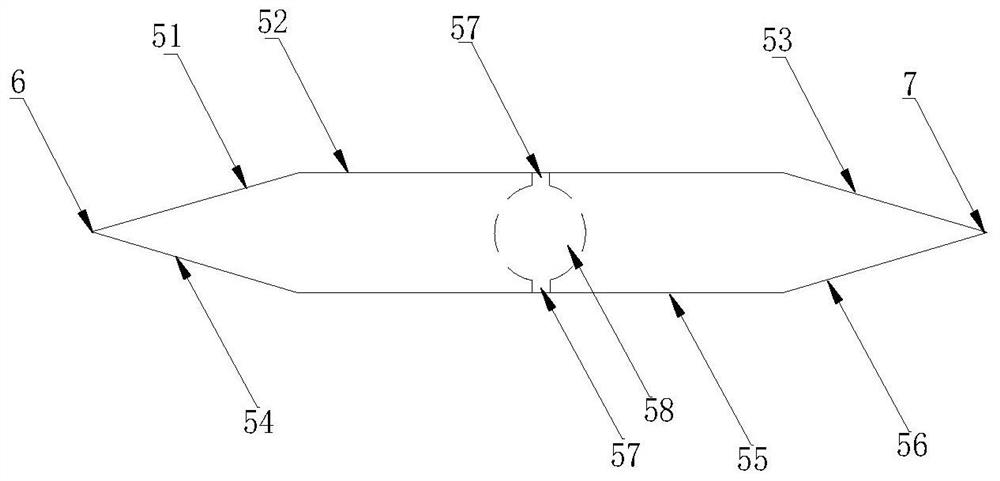

[0024] Embodiment: a kind of combustor spans to support plate, as figure 1 and figure 2 As shown, it includes a support plate body 5 installed in the middle of the dual structure combustion chamber to divide the combustion chamber into upper and lower parts. The support plate body 5 includes a first slope 51 close to the upstream direction of the airflow, and a second slope 54 close to the upstream direction of the airflow. , an upper plane 52 near the end of the first slope 51 parallel to the airflow direction, a lower plane 55 near the end of the second slope 54 parallel to the upper plane 52, a third slope 53 near the downstream direction of the airflow, and a third slope near the downstream direction of the airflow Four inclined planes 56 . The end of the support plate body 5 close to the upstream direction of the airflow forms a first taper angle 6 by the first slope 51 and the second slope 54 . The end of the support plate body 5 close to the downstream direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com