Method for preparing high-adsorption nano-crystalline cellulose polyvinylamine microgel by using biomass

A polyvinylamine microgel and nanocellulose technology, which is applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve problems such as unsatisfactory adsorption effects, achieve large specific surface area, Good development prospects, easy to reuse the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

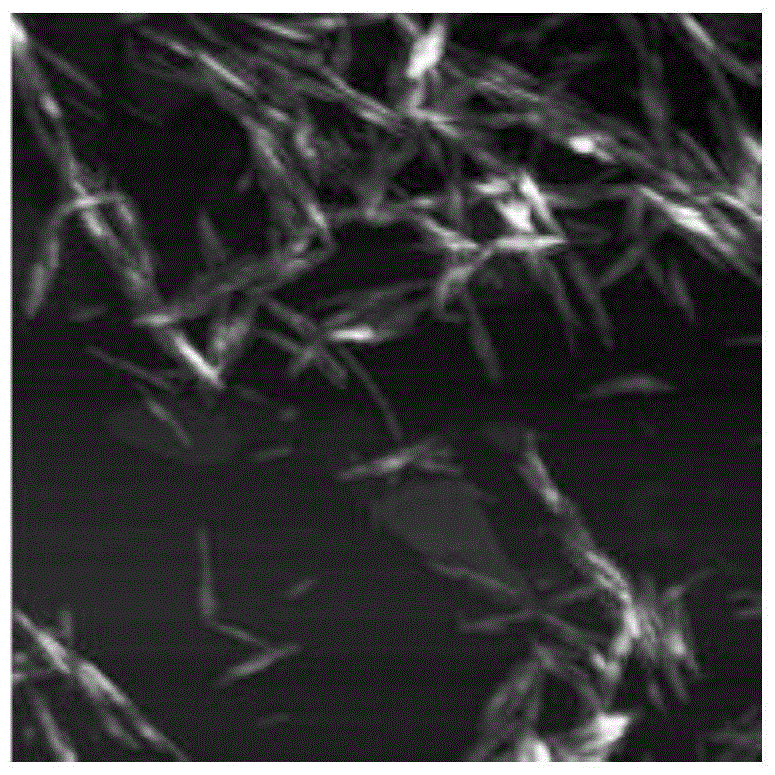

[0039] (1) Pulverize the bleached hardwood pulp with a pulverizer, pass through a 20-mesh sieve, and take as 20 g of dry pulp. Add 170mL of sulfuric acid with a mass concentration of 64% at 45°C and mix, and react under the action of mechanical stirring. After reacting for 30min, the suspension is diluted 10 times with deionized water to terminate the reaction. The product was centrifuged repeatedly with deionized water until the pH value was 5.0. Put the precipitate after centrifugation into a dialysis bag with a molecular weight cut off of 12000-14000, and dialyze with flowing deionized water for 5 days. The dialyzed suspension was treated with an ultrasonic oscillator for 10 minutes. In order to avoid product aggregation due to heat, the ultrasonic treatment was carried out in an ice-water bath to obtain a nanocrystalline cellulose (NCC) suspension.

[0040] (2) Take the NCC suspension containing 1 g of dry material, add 6 mmol of sodium periodate, adjust the pH to 3.5 wit...

Embodiment 2

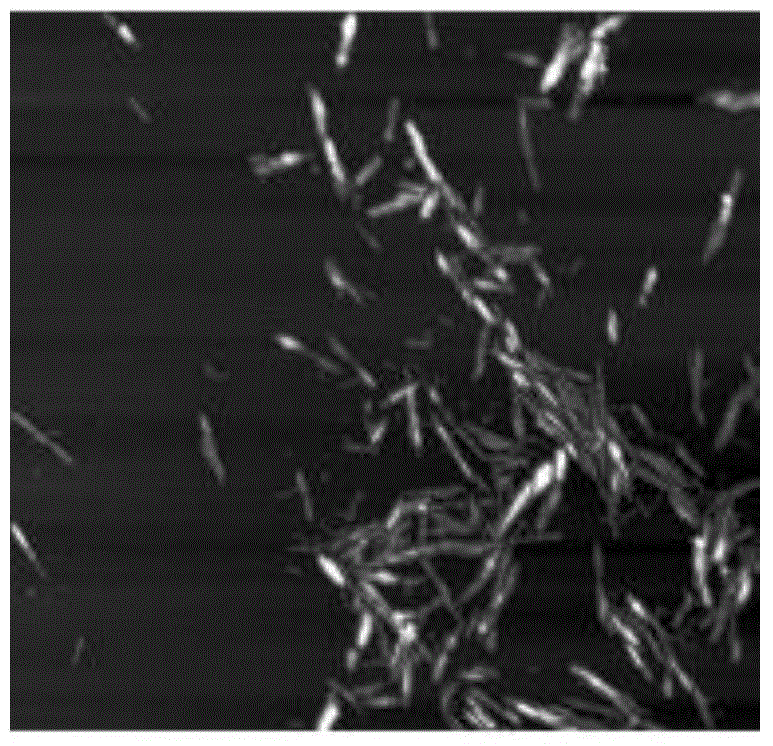

[0045] (1) Pulverize the bleached hardwood pulp with a pulverizer, pass through a 20-mesh sieve, and take as 20 g of dry pulp. Add 170ml of sulfuric acid with a mass concentration of 64% at 45°C and mix, react under mechanical stirring for 30min, and then dilute the suspension 10 times with deionized water to terminate the reaction. The product was centrifuged repeatedly with deionized water until the pH value was 5.0. Put the precipitate after centrifugation into a dialysis bag with a molecular weight cut off of 12000-14000, and dialyze with flowing deionized water for 5 days. The dialyzed suspension was treated with an ultrasonic oscillator for 10 minutes. In order to avoid product aggregation due to heat, the treatment was carried out in an ice-water bath to obtain a nano-microcrystalline cellulose suspension.

[0046] (2) Take the NCC suspension containing 1 g of dry material, add 9 mmol of sodium periodate, adjust the pH to 3.5 with 0.5 mol / L sulfuric acid, and dilute to...

Embodiment 3

[0049] (1) Pulverize the bleached coniferous wood pulp with a pulverizer, pass through a 20-mesh sieve, and take as 20 g of dry pulp. Add 170ml of sulfuric acid with a mass concentration of 64% at 45°C and mix, and react under the action of mechanical stirring. After reacting for 30 minutes, dilute the suspension 10 times with deionized water to terminate the reaction. The product was centrifuged repeatedly with deionized water until the pH value was 5.0. Put the precipitate after centrifugation into a dialysis bag with a molecular weight cut off of 12000-14000, and dialyze with flowing deionized water for 5 days. The dialyzed suspension was treated with an ultrasonic oscillator for 10 minutes. In order to avoid product aggregation due to heat, the treatment was carried out in an ice-water bath to obtain a nano-microcrystalline cellulose suspension.

[0050] (2) Take the NCC suspension containing 1 g of dry material, add 12 mmol of sodium periodate, adjust the pH to 3.5 with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com