Adhesive tape for sealing boxes and manufacturing method thereof

A technology for adhesive tapes and boxes, applied in adhesives, packaging sealing/fastening, film/sheet adhesives, etc., can solve problems such as increased warehouse pressure, capital loss, and increased production costs, and reduce production cost, solve the warehouse pressure, and reduce the effect of capital loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation process and beneficial effects of the present invention will be described in detail below in conjunction with specific examples, but this does not constitute any limitation to the implementation scope of the present invention.

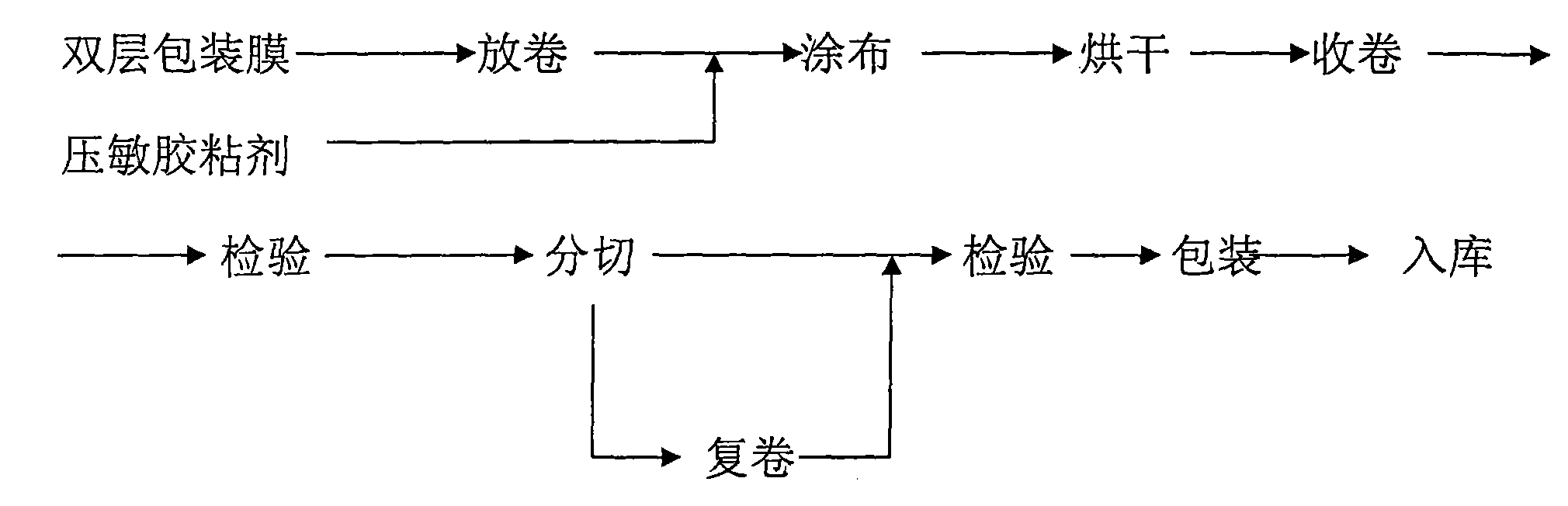

[0027] figure 1 A flow chart of a specific manufacturing process of the present invention is shown. Unwind the packaging film base material (double-layer composite film), apply anti-freeze pressure-sensitive adhesive on the determined surface, rewind after drying, cut the qualified products according to the use needs, and pass the inspection again ( Rewinding can be carried out according to requirements) and then packaged and put into storage.

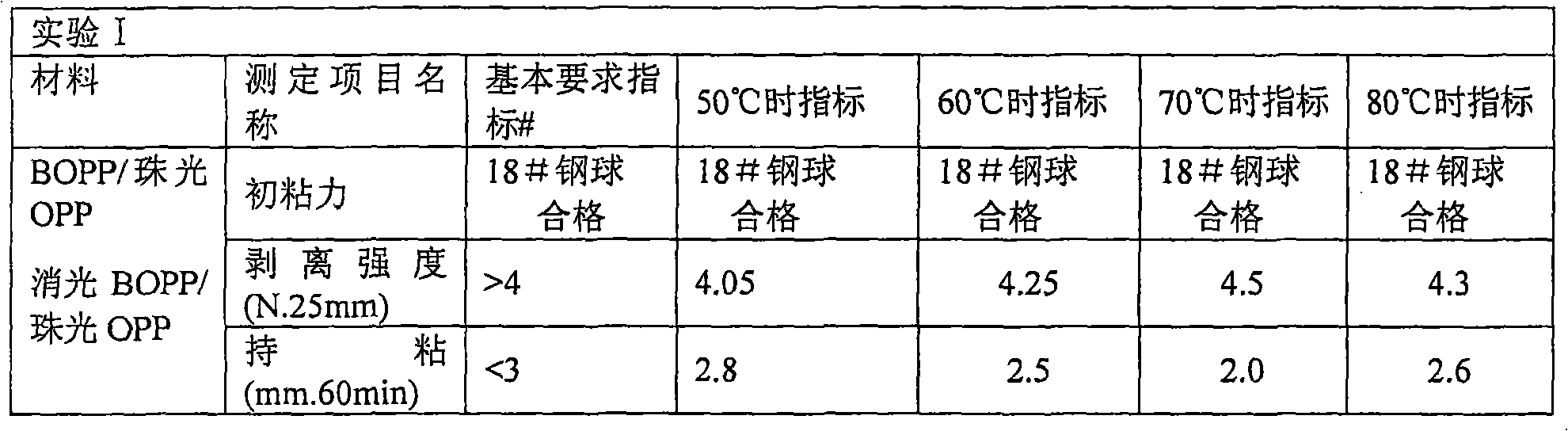

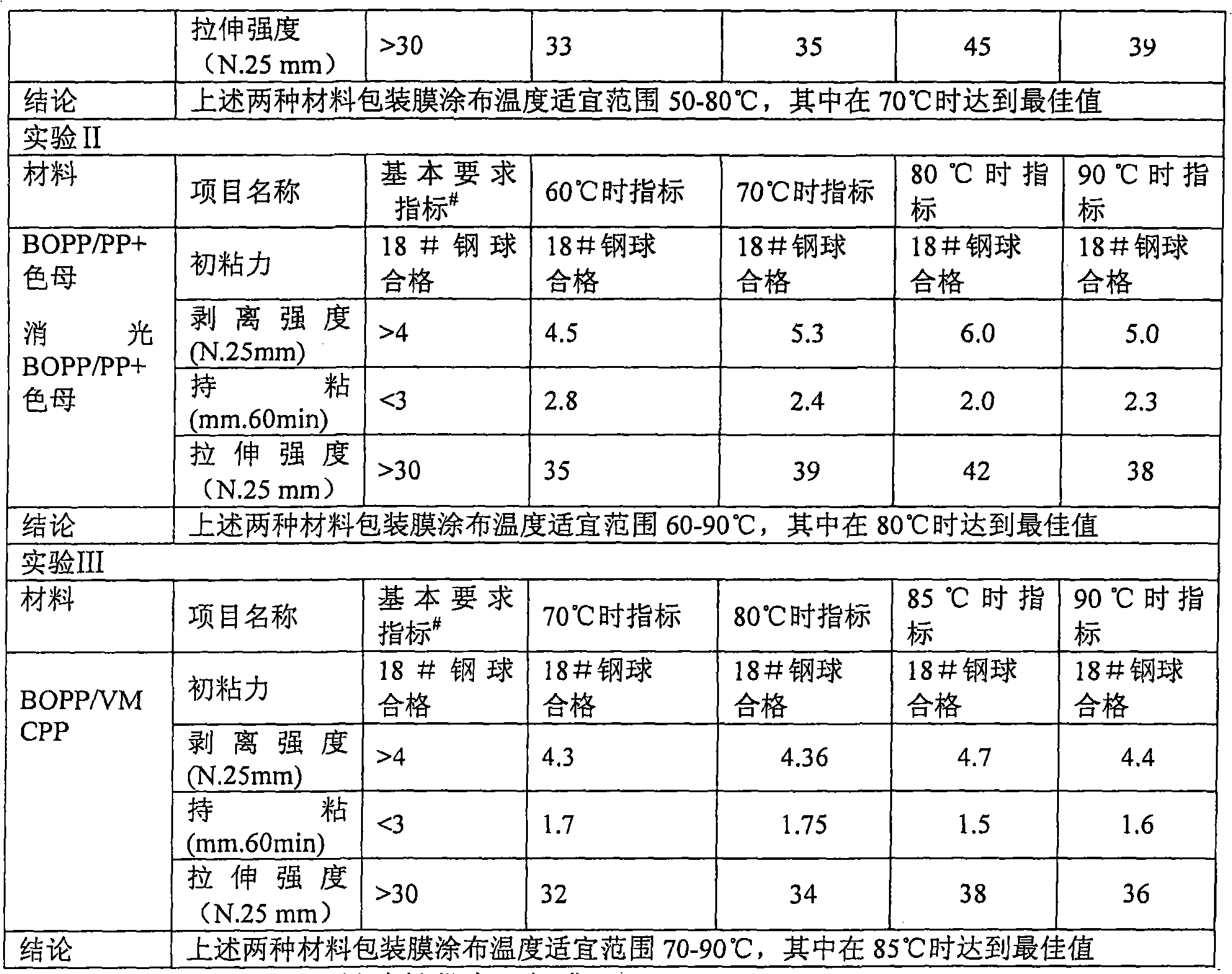

[0028] Applicable packaging film substrates can be BOPP / pearl OPP, matte BOPP / pearl OPP, BOPP / PP+color masterbatch, matte BOPP / PP+color masterbatch or BOPP / VMCPP and other commonly used double-layer polypropylene composite films for cold drink products, among which, There are printed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com