A kind of preparation method of cyclopropylamine intermediate methyl cyclopropanate

A technology of methyl cyclopropanate and intermediates, which is applied in the field of preparation of cyclopropylamine intermediate methyl cyclopropanate, which can solve the problems of incomplete reaction, difficult to control yield, high impurity content of products, etc., so as to avoid environmental pressure , Reduce the cost of raw materials, the effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

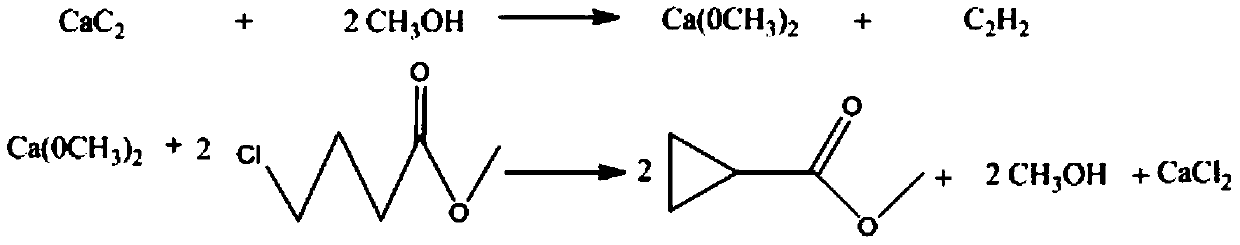

Method used

Image

Examples

Embodiment 1

[0020] In a 1000ml reactor, add 1 mol of calcium carbide, seal it and replace the air with nitrogen for 3 times, then start to add 4 mol of methanol dropwise, and collect acetylene gas until the reaction is completed. Then add 1.8mol of methyl γ-chlorobutyrate dropwise to the reactor, control the drop rate and keep the temperature constant at 100°C, and collect the methanol fraction generated during the dropwise addition process. After the reaction is over, collect the fraction by heating up and distilling , 170.3 g of methyl cyclopropanecarboxylate was obtained, and the yield was 94.5%.

Embodiment 2

[0022] In a 1000ml reactor, add 1 mol of calcium carbide, seal it and replace the air with nitrogen for 3 times, then start to add 2 mol of methanol dropwise, and collect acetylene gas until the reaction is completed. Then add 1.8mol of methyl γ-chlorobutyrate dropwise to the reactor, control the drop rate and keep the temperature constant at 100°C, and collect the methanol fraction generated during the dropwise addition process. After the reaction is over, collect the fraction by heating up and distilling , 150.1 g of methyl cyclopropanate was obtained, with a yield of 83.3%.

Embodiment 3

[0024] In a 1000ml reactor, add 1mol of calcium carbide, seal it and replace the air with nitrogen for 3 times, then start to add 6mol of methanol dropwise, and collect acetylene gas until the reaction is completed. Then add 1.8mol of methyl γ-chlorobutyrate dropwise to the reactor, control the drop rate and keep the temperature constant at 100°C, and collect the methanol fraction generated during the dropwise addition process. After the reaction is over, collect the fraction by heating up and distilling , 120.5 g of methyl cyclopropanate was obtained, with a yield of 66.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com