Method for treating chlorosilane slurry residual liquid

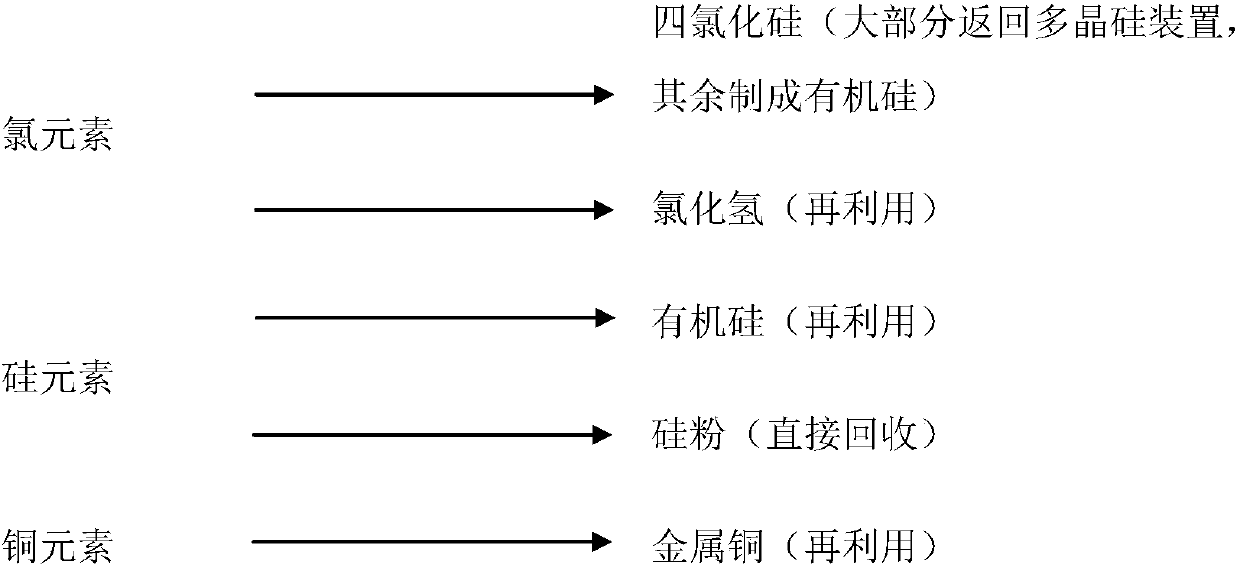

A technology of chlorosilane and slurry, which is applied in the direction of halosilane, chemical instruments and methods, silicon compounds, etc., can solve the problems of no metal and copper recovery reports, achieve convenient recovery, reduce production costs, reduce lye and The effect of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

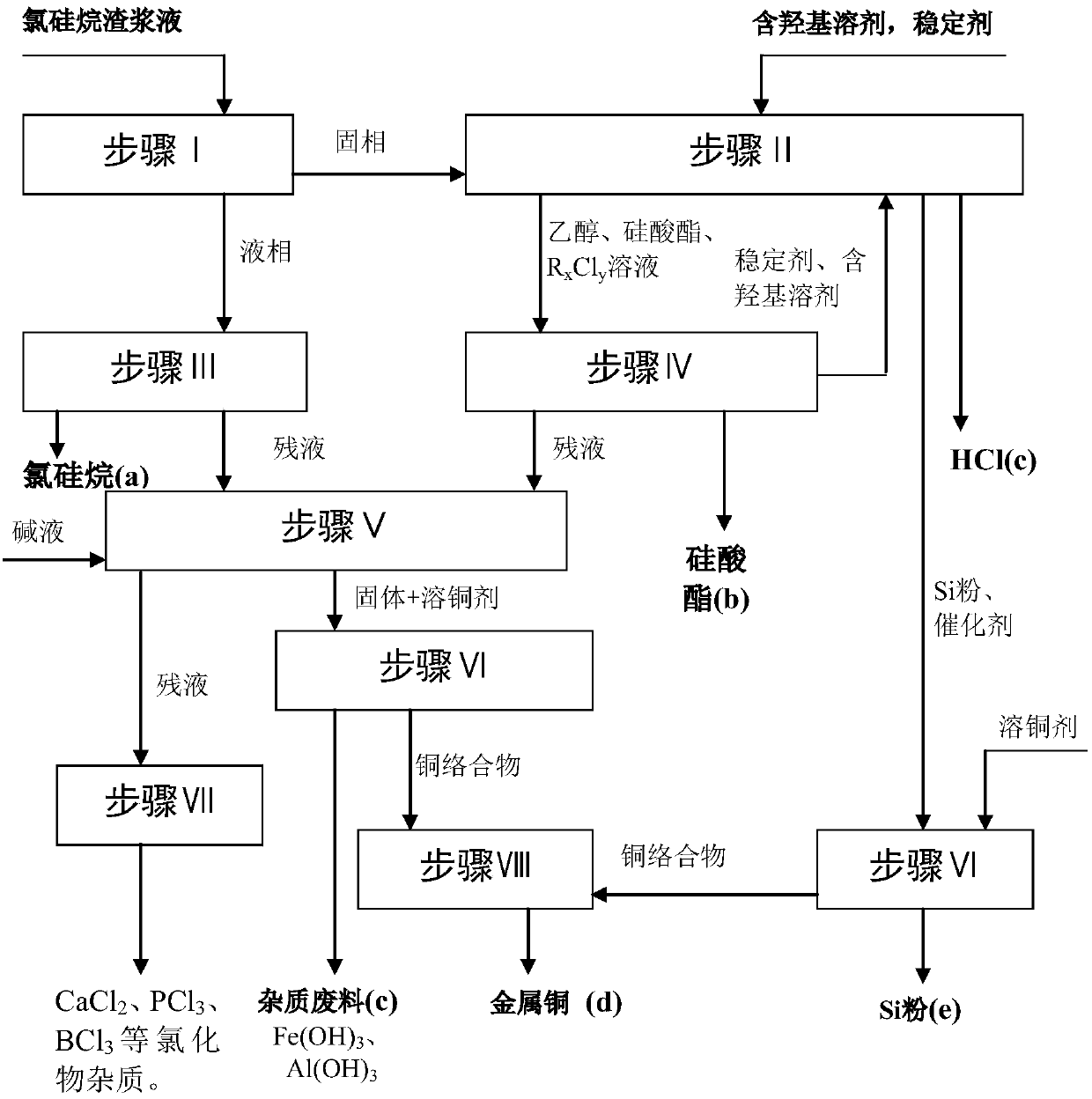

Method used

Image

Examples

Embodiment 1

[0090] The chlorosilane slurry raffinate treated here is taken from a cold hydrogenation unit in a certain polysilicon production, and its main components are shown in Table 1:

[0091] Table 1 Composition of slurry raffinate

[0092] main ingredient

Mass fraction (wt)%

83.31%

0.13%

3.85%

Dichlorodihydrosilane

0.13%

Other metal chlorides

3.56%

Phosphorus trichloride

2.31%

Methyldichlorosilane

0.01%

0.00%

3.18%

1.54%

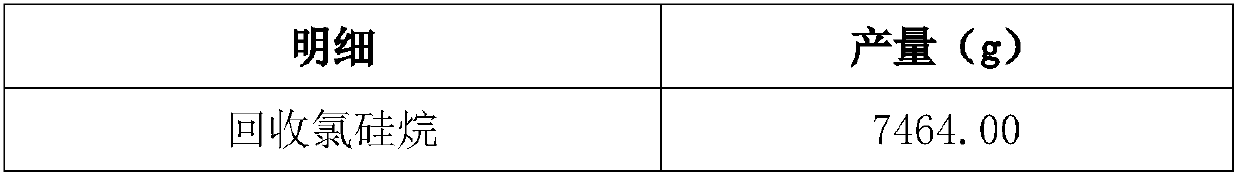

[0093] Take 10,000g of chlorosilane slurry residue and transport it to the preliminary recovery step I as shown in the accompanying drawing. After standing for a period of time, the solids will settle at the bottom of the container, and the upper layer is a chlorosilane solution with a lower solid content. After the upper layer solution is separated, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com