Method for preparing silicate ester by recycling chlorosilane slag slurry residual liquid

A chlorosilane and silicate technology, which is applied in the field of recovering chlorosilane slurry residue to prepare silicate, can solve problems such as environmental pressure and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

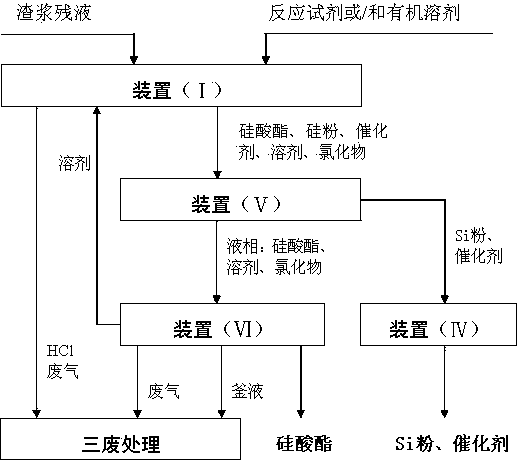

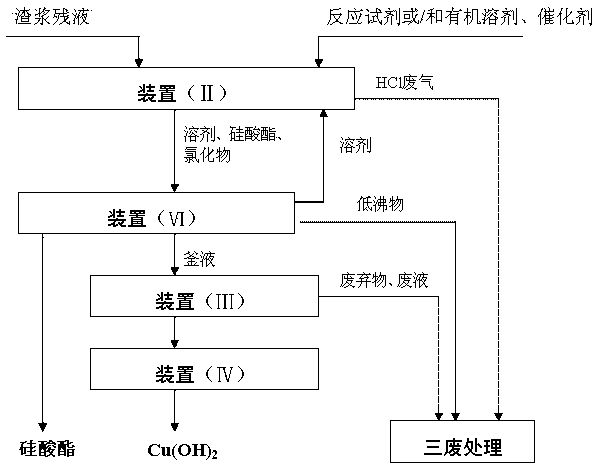

Image

Examples

Embodiment 1

[0049] The chlorosilane slurry raffinate treated here is taken from the cold hydrogenation unit in polysilicon production, and its main components are shown in Table 2:

[0050] Table 2 Main components in slurry raffinate

[0051] components main ingredient Content (WT)% Chlorosilane STC 73.0 catalyst CuCl 5.0 Silica fume Si powder 14.0 other High boilers, chlorides 8.0

[0052] Take 200g of chlorosilane slag slurry, let it stand for a period of time, let the solid settle at the bottom of the container, and the upper layer is a relatively clear chlorosilane solution. After the upper layer solution was sucked out, it weighed 116.0g, and its main component was STC, but the impurity content was relatively high, and the main content of STC was 94%. It must be rectified to meet the requirements of cold hydrogenation STC raw material. Nitrogen gas at about 100°C is introduced into the solid to try to blow away the incompletely separa...

Embodiment 2

[0054] Take 200.0 g of the same chlorosilane slag slurry as in Example 1 as the initial raw material, first add about 30.0 g into a 1000 ml reaction flask, and then slowly add the remaining slag residue and 200.0 g of absolute ethanol at the same time at room temperature, while adding While stirring, the temperature of the system gradually increased, and hydrogen chloride gas was continuously generated. Condensate the reaction tail gas with condensed water at 25°C and discharge it into the alkaline solution for absorption. Since the esterification reaction between chlorosilane and ethanol is very fast, the reaction is basically completed after the addition is completed and the stirring is continued for 0.5 h. Stirring was stopped to obtain a viscous yellow-green solution. After standing for a while, it was observed that the solids all sank to the bottom of the reactor, and the upper layer was a cleaner liquid.

[0055] Using a suction filtration device, transfer the reaction ...

Embodiment 3

[0067] Get 20.00g of the silicon powder recovered in Example 1 as the initial material, slowly add it into a reaction flask filled with 100ml of ethanol, stir while adding, heat will be released continuously, if adding too fast or insufficient stirring, bumping will occur, After the addition, start heating and stirring, make the silicon powder and ethanol react under reflux (82°C) for 5 hours, then stop heating. After the reaction solution was cooled to room temperature, the reaction solution was transferred to a suction filter funnel for suction filtration. The filtrate was a viscous slightly yellow liquid, and the filter cake was a black solid. The filter cake was rinsed three times with 30g*3 absolute ethanol, and finally drained to obtain a black solid substance with metallic luster, which weighed 13.6g after drying. The filtrates were combined, and the filtrate was distilled at atmospheric pressure with a distillation device. After all the solvents were evaporated, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com