Bio-based asphalt mixture modifier, preparation method and application

A technology of asphalt mixture and bio-based filler, which is applied in the direction of building structure, building insulation materials, building components, etc., and can solve the problem of water damage resistance, low temperature cracking resistance, no promotion, increased road cost, and adverse effects, etc. problems, to achieve the effect of reducing the expansion of the industrial chain, saving costs, and solving environmental pressures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

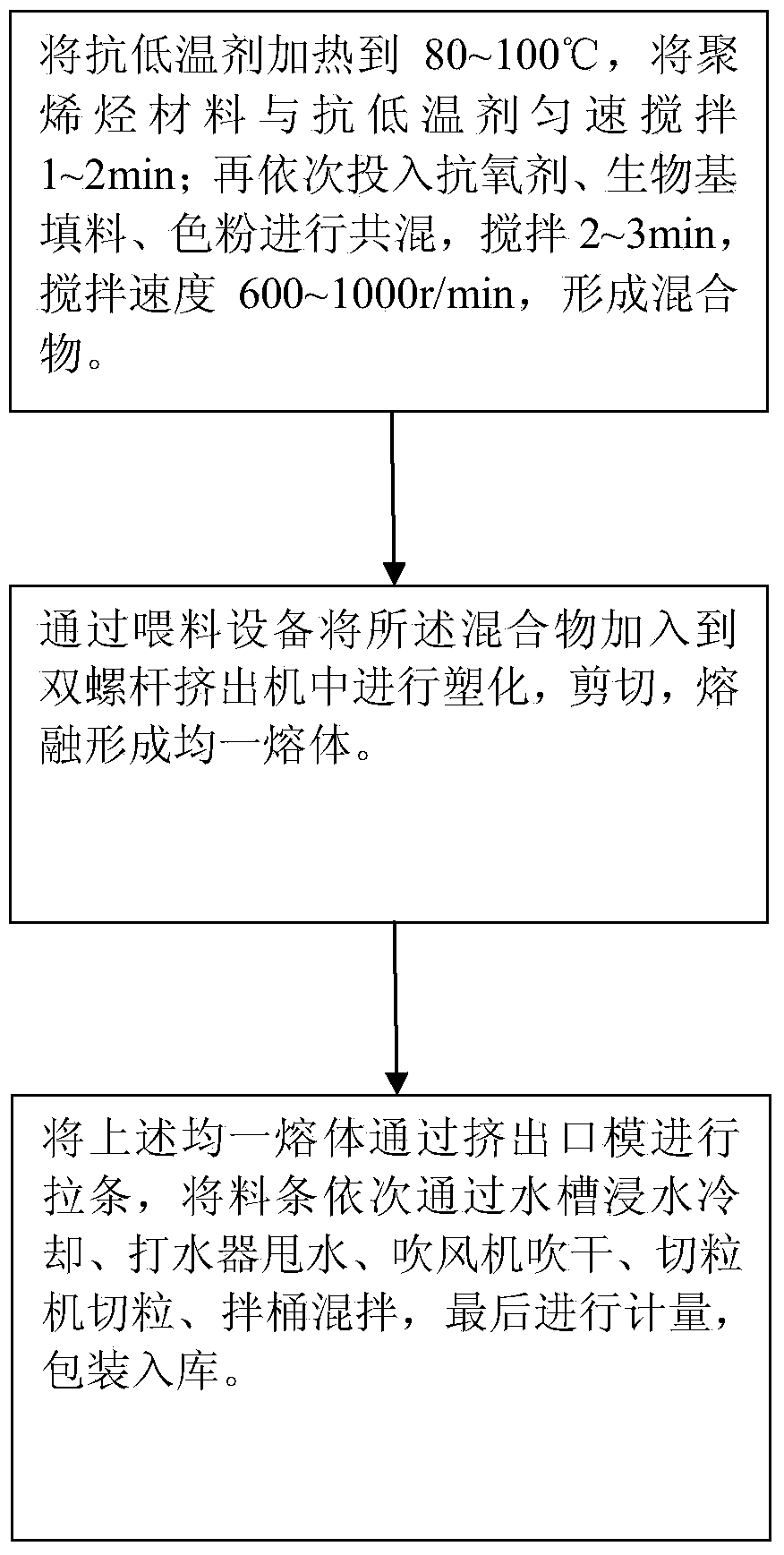

[0018] Shown in Fig. 1 with reference to, the preparation method of asphalt mixture modifier of the present invention comprises the steps:

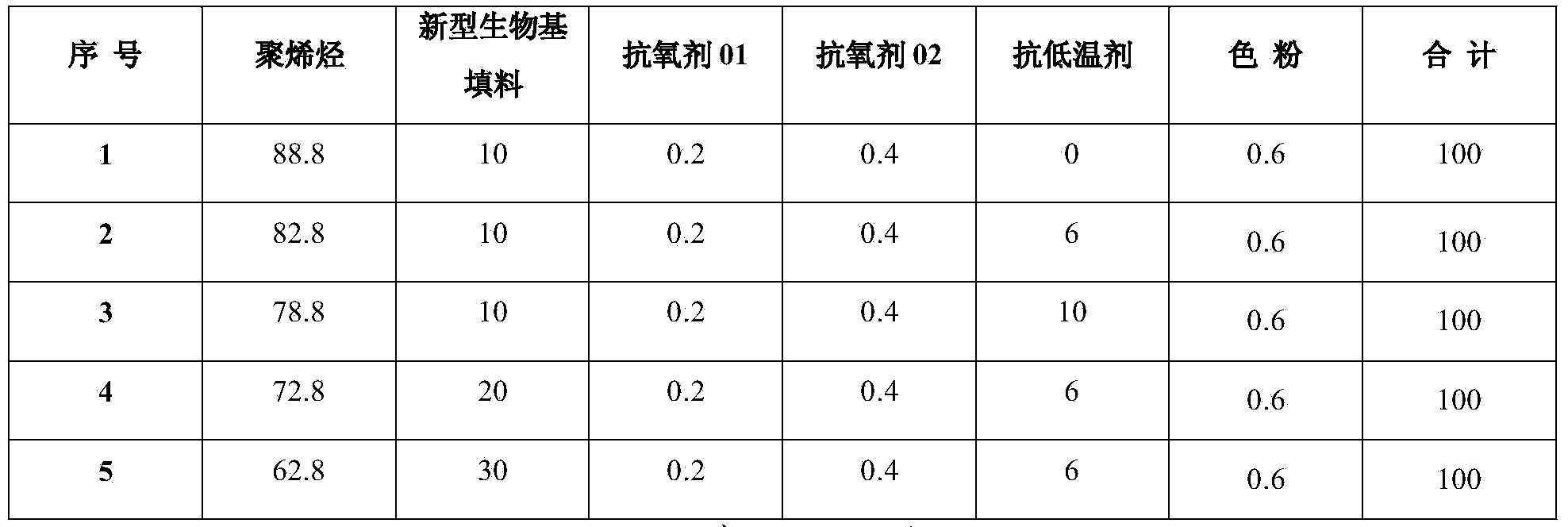

[0019] Heat the anti-low temperature agent to 80-100°C, then stir the polyolefin material and the anti-low temperature agent at a constant speed for 1-2 minutes; then put in the antioxidant, new bio-based filler, and toner in sequence for blending and stirring, and the stirring time is 2 ~3min, the stirring speed is 600~1000r / min; it is to ensure the uniform mixing of materials, which is beneficial to subsequent processing and molding;

[0020] Add the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com