Catalyst for catalyzing amine salt conversion, preparation method of the catalyst and preparation method of DAM

A technology for catalyzing amine salts and catalysts, which is applied in the field of preparation of diamines and polyamines. It can solve problems such as environmental protection discharge or recycling pressure, corrosion of acid-resistant equipment, and long-term stable operation of devices, so as to reduce activation energy and disperse Uniform, excellent catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

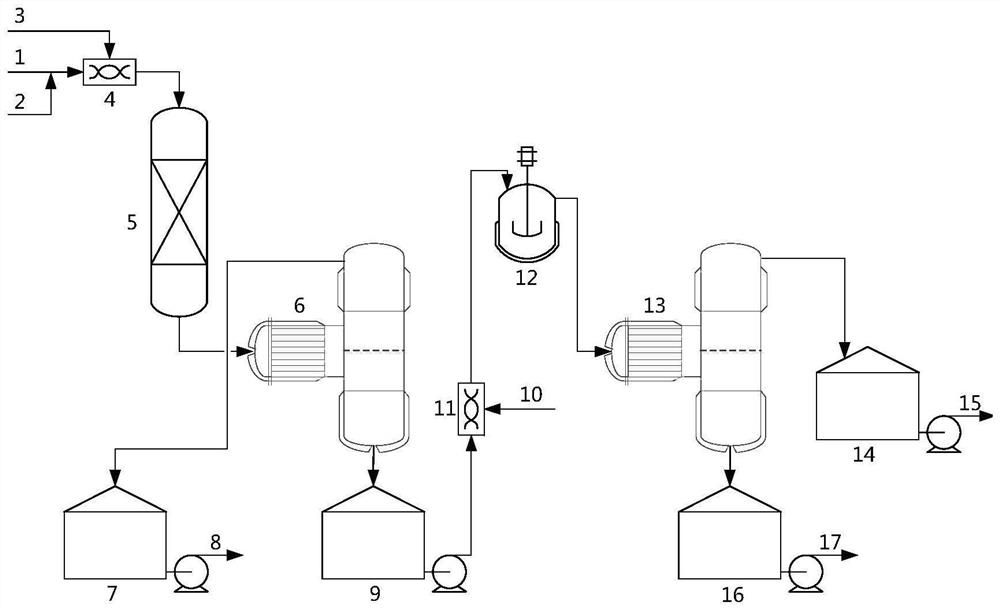

Image

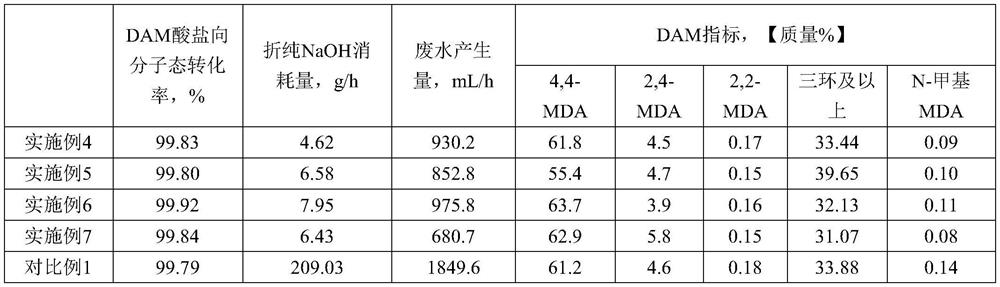

Examples

Embodiment 1

[0066] Embodiment 1: the preparation of 1# catalyst

[0067] a) Preparation of nano-TiO 2 Carrier: Measure 24 mL of butyl titanate into a 1000 mL three-neck flask, add a mixed solution of 150 mL of ethanol and 150 mL of pure water, then add 30 mL of acetic acid, and stir for 10 min at 25°C and 300 r / min. Measure 180mL of ethanol solution containing 20wt% urea, slowly add it into the flask at a rate of 3.6mL / min, keep stirring at 300r / min, and heat the solution in the flask to 160°C at a heating rate of 10°C / min and maintain 160°C, after the addition of the urea-ethanol solution, cool to 50°C after 8 minutes, separate the precipitate, and use absolute ethanol to ultrasonically clean it 5 times, each time using 20mL of ethanol. Then the cleaned solid was dried in an oven at 160°C for 40min, and then calcined in a muffle furnace at 320°C for 2h to obtain TiO with an average particle size of 15nm. 2 carrier.

[0068] b) Loading active components: weigh 1.96g praseodymium nitrat...

Embodiment 2

[0069] Embodiment 2: the preparation of 2# catalyst

[0070] a) Preparation of nano-TiO 2 Carrier: Measure 20 mL of butyl titanate into a 1000 mL three-necked flask, add a mixed solution of 150 mL of ethanol and 150 mL of pure water, then add 40 mL of acetic acid, and stir for 10 min at 25°C and 300 r / min. Measure 180mL of ethanol solution dissolved with 18wt% urea, slowly add it into the flask at a rate of 3.6mL / min, keep stirring at 300r / min, and heat the solution in the flask to 160°C at a heating rate of 10°C / min and maintain 160°C, after the addition of the urea-ethanol solution, cool to 50°C after 6 minutes, separate the precipitate, and use absolute ethanol to ultrasonically clean it 3 times, each time using 30mL of ethanol. Then the cleaned solid was dried in an oven at 160°C for 50min, and then calcined in a muffle furnace at 320°C for 2.5h to obtain TiO with an average particle size of 48nm. 2 carrier.

[0071] b) Loading active components: weigh 2.45g praseodymiu...

Embodiment 3

[0072] Embodiment 3: the preparation of 3# catalyst

[0073] a) Preparation of nano-TiO 2 Carrier: Measure 42 mL of butyl titanate into a 1000 mL three-necked flask, add a mixed solution of 150 mL of ethanol and 150 mL of pure water, then add 30 mL of acetic acid, and stir for 10 min at 25°C and 300 r / min. Measure 180mL of ethanol solution containing 22wt% urea, slowly add it into the flask at a rate of 3.6mL / min, keep stirring at 300r / min, and heat the solution in the flask to 160°C at a heating rate of 10°C / min and maintain 160°C, after the addition of the urea ethanol solution, cool to 50°C after 10 minutes, separate the precipitate, and use absolute ethanol to ultrasonically clean it 3 times, each time using 40mL of ethanol. Then the cleaned solid was dried in an oven at 160°C for 40min, and then calcined in a muffle furnace at 320°C for 3h to obtain TiO with an average particle size of 29nm. 2 carrier.

[0074] b) Loading active components: weigh 2.94g praseodymium nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com