Dry kiln interior desulfurizer for smelting ferronickel through RKEF method

A desulfurization device and drying kiln technology, applied in the direction of furnace type, furnace, rotary drum furnace, etc., can solve the problem of high desulfurization cost, achieve the effect of improving the reaction effect, promoting drying and desulfurization, and the effect of novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

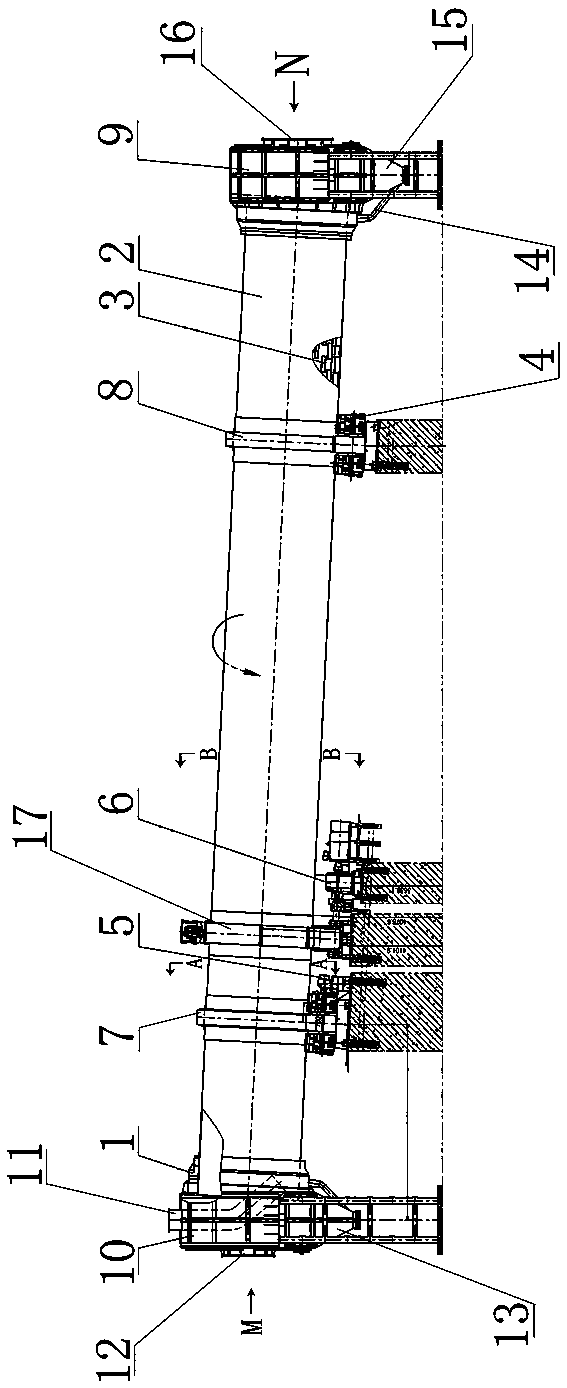

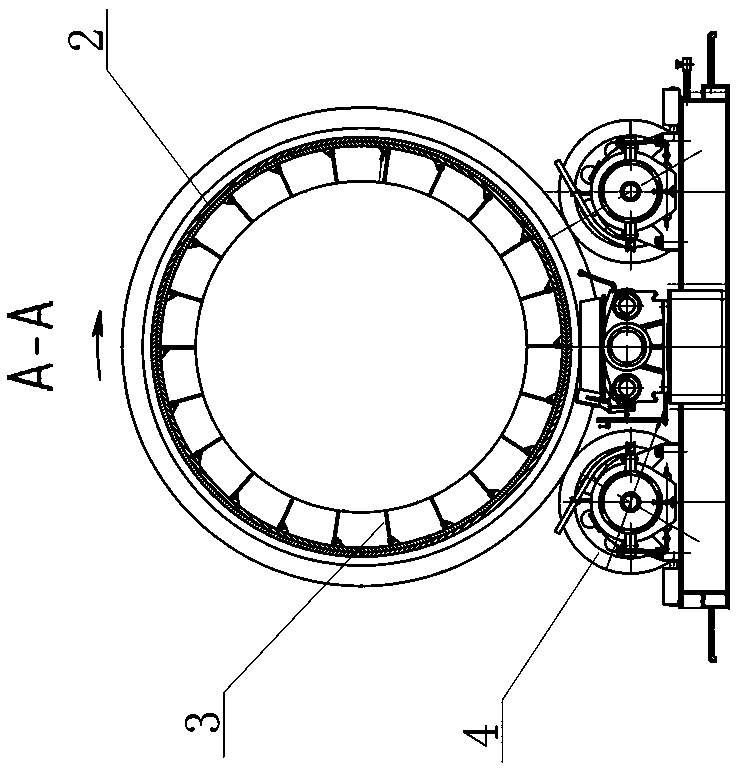

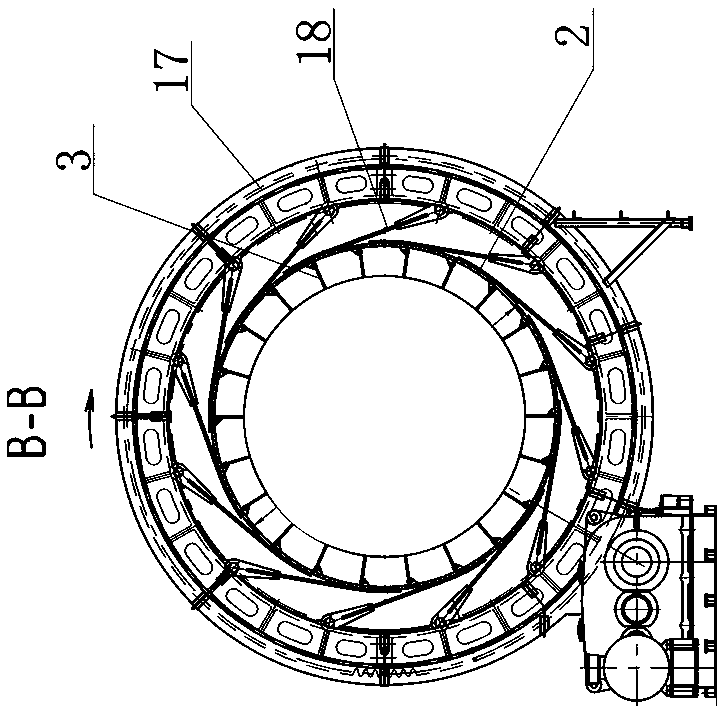

[0032] refer to Figure 1 to Figure 5 , the present invention includes a cylinder 2, and the inner diameter of the cylinder 2 is evenly provided with a number of lifting plates 3; the cylinder 2 is inclined, and the front end of the cylinder 2 is lower than the rear end of the cylinder;

[0033] The front end of the cylinder 2 is provided with an air inlet 16, and the rear end of the cylinder 2 is provided with an air outlet 12; the front end and the rear end of the cylinder 2 are connected to the kiln head cover 9 and the kiln tail cover 10 respectively through bearing seats. Rotating connection; the top of the kiln head cover 9 is provided with a feed pipe 11 communicating with the rear end of the cylinder body 2, and the bottom of the kiln head cover 9 is provided with an ash discharge bucket 13; the kiln tail cover 10 is provided with a The lower hoppers 15 connected to each other at the front ends of the cylinder body 2;

[0034] The front and rear parts of the cylinder ...

Embodiment 2

[0042] A desulfurizer, which is prepared according to the following process:

[0043]1) Crush wheat straw with a pulverizer, then add it to 2M sodium carbonate aqueous solution, soak for 10 hours, filter, air-dry, and grind to 20-mesh powder to obtain component A;

[0044] 2) Add activated carbon, manganese acetate and ferric chloride to water at a mass ratio of 50:2:1, heat and stir in a magnetic stirrer until dry, then put it in a drying oven at 80°C for 30 minutes, and finally grind until the particle size is 100 mesh, component B is obtained;

[0045] 3) Mix dolomite and kaolin at a mass ratio of 1:1, and then place them in a calcination furnace for 3 hours at a calcination temperature of 700°C, take them out, pulverize them, and cool to room temperature to obtain component C;

[0046] 4) Control the particle size of calcium oxide, calcium fluoride and dicalcium silicate to be 50 mesh, then add them to the mixing mixer according to the mass ratio of 2:1:1, stir at 600rpm ...

Embodiment 3

[0049] The effect test of the desulfurizer prepared by the embodiment of the present invention 2:

[0050] Take 10g of desulfurizer, place it in the reactor for experiment, simulate and detect sulfur-containing gas, the conditions are as follows: SO 2 The sulfur-containing gas composed of , NOx and dust is blown into the reaction system to control SO 2 The concentration is 16mg / m 3 , NOx concentration is 10mg / m 3 , dust 8mg / m 3 , the reaction space velocity (GHSV) is 80,000h -1 , The reaction time is 60min.

[0051] Set up four groups respectively: Example 2; Control group 1: No component A added; Control group 2: No component B added; Control group 3: No component C added.

[0052] The adsorption capacity of the adsorbent to harmful substances was detected (hazardous substance / adsorbent=mg / g), and the results are shown in Table 1.

[0053] Table 1

[0054] group

[0055] Conclusion: As shown in the above table 1, the desulfurization agent of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com