Hyaluronic acid-glucosamine grafted copolymer, and preparation method and application thereof

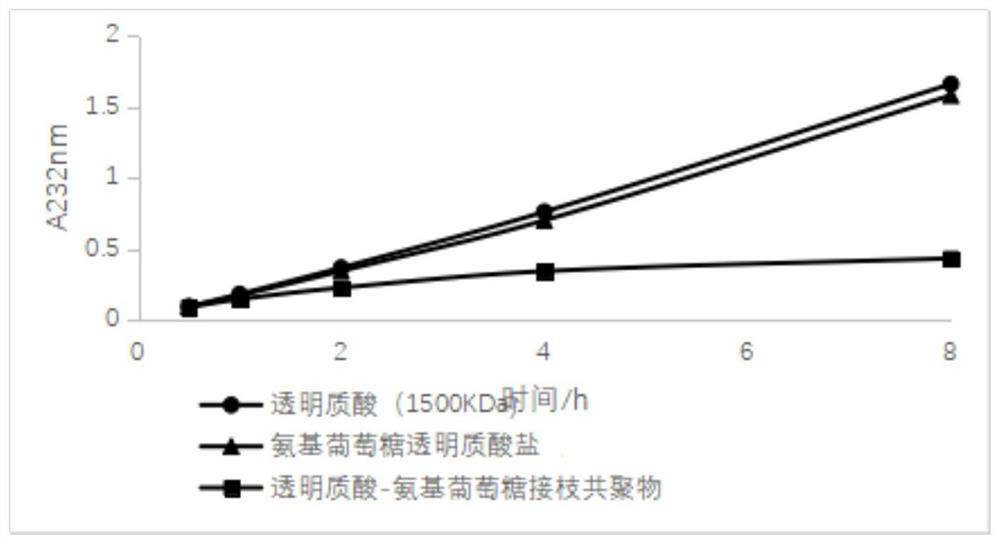

A technology of glucosamine and graft copolymers, applied in the field of hyaluronic acid modification, which can solve the problems of poor stability, sensitivity to free radicals and hyaluronidase, and easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

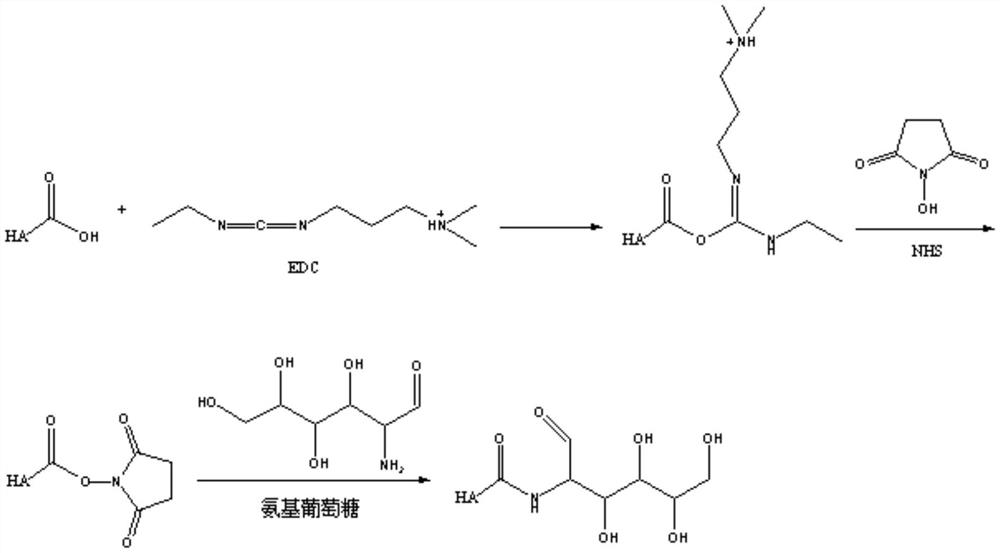

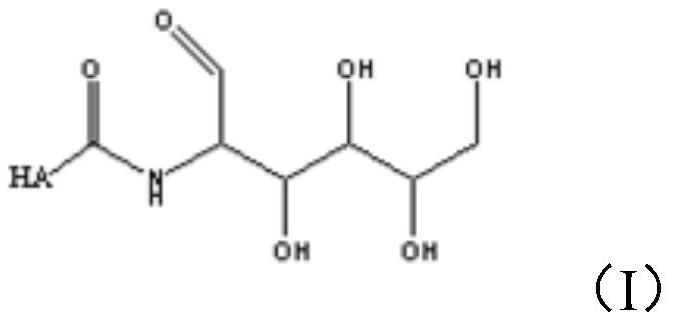

[0044] The invention provides a kind of preparation method of hyaluronic acid-glucosamine graft copolymer, it comprises the following steps:

[0045] mixing the condensing agent, glucosamine or its salt and water to obtain a mixed solution;

[0046] The pH value of the mixed solution is adjusted, and then hyaluronic acid or its salt is added for amidation reaction to obtain a hyaluronic acid-glucosamine graft copolymer.

[0047] For the condensing agent, the present invention has no limitation, as long as the carboxyl group of hyaluronic acid or its salt can be amidated with the amino group of glucosamine or its salt, for example, the use of carbodiimides and succinyl A composite condensing agent composed of imine substances, or a composite condensing agent composed of carbodiimide substances and benzotriazole substances, or a composite condensing agent composed of carbodiimide substances, benzotriazole substances and succinyl A composite condensing agent composed of amine su...

Embodiment 1

[0102] (1) At room temperature, add 4.79g of EDC, 2.88g of NHS and 13.86g of glucosamine sulfate to 100ml of purified water in sequence, and completely dissolve to obtain a mixed solution;

[0103](2) Use NaOH solution to adjust the pH value of the mixed solution to 9.0, then add 10g of hyaluronic acid (1500kDa) to the above solution while stirring, disperse evenly, put it at 4°C to activate for 10-30min, then take it out and place it React at room temperature for 4 hours. After the reaction is completed, add 200ml of purified water to dilute the reaction solution, then add 2.5 times the volume of ethanol for the dilution to precipitate, adjust the pH value of the precipitate suspension to 7.0 with hydrochloric acid, let it stand for a while, discard The supernatant was removed, the precipitate was repeatedly washed with ethanol and dehydrated 3 times, and finally the liquid was removed by suction filtration to obtain a wet powder, which was placed at 40°C for vacuum drying to ...

Embodiment 2

[0112] (1) At room temperature, add 9.58g of EDC, 5.75g of NHS and 13.86g of glucosamine sulfate to 100ml of purified water in sequence, and completely dissolve to obtain a mixed solution;

[0113] (2) Use NaOH solution to adjust the pH value of the mixed solution to 8.0, then add 10g of hyaluronic acid (900kDa) to the above solution while stirring, disperse evenly, put it at 4°C for 10-30min, and then take it out and place it React at room temperature for 8 hours. After the reaction is completed, add 200ml of purified water to dilute the reaction solution, and then add 2.5 times the volume of ethanol to precipitate the diluted solution. Use hydrochloric acid to adjust the pH value of the precipitated suspension to 7.0. After standing for a period of time, discard The supernatant and the precipitate were repeatedly washed with ethanol and dehydrated 3 times, and finally the liquid was removed by suction filtration to obtain a wet powder. The wet powder was placed in 40°C for va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com