Special beet liquid fertilizer prepared from yeast concentrate

A yeast concentrate and liquid fertilizer technology, applied in liquid fertilizer, inorganic fertilizer, organic fertilizer, etc., can solve problems such as pollution, land pollution, and aggravation of land pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A special liquid fertilizer for sugar beet prepared by using yeast concentrate, which is prepared by the following method:

[0059] (1) Add sulfuric acid solution to the yeast concentrate, stir and react to obtain the first reaction liquid;

[0060] Among them, the mass percentage concentration of the sulfuric acid solution is 25%, the volume ratio of the yeast concentrate to the sulfuric acid solution is 8:1, and the reaction time is 0.5h.

[0061] (2) Pass the EM bacterial solution into the first reaction solution, and then perform fermentation and aeration treatment at 25-30°C for 5.5 hours under light conditions to obtain the second reaction solution;

[0062] The EM bacterial liquid contains lactic acid bacteria, Bacillus subtilis, Bacillus licheniformis, yeast, nitrifying bacteria, photosynthetic bacteria and carriers, and the effective number of viable bacteria is ≥10 billion / g. The mass ratio of the first reaction liquid to the EM bacterial liquid is 100:0.3. The EM ba...

Embodiment 2~6

[0070] The preparation process is basically the same as that of Example 1. The products include special flush fertilization during the luxuriant period of sugar beet leaves and special flush fertilization during the growth period of sugar beet roots. The changed parameters are shown in Table 1.

[0071] Table 1

[0072] Example Variable parameters Example 2 In step (1), no sulfuric acid solution was added to the yeast concentrate, and other preparation processes were the same as in Example 1. Example 3 In step (2), no EM bacteria liquid was added, only aeration treatment was performed, and other preparation processes were the same as in Example 1. Example 4 No synergist is added in step (4), and other preparation processes are the same as in Example 1. Example 5 In step (5), ammonia was not used to adjust the pH value to 6-7, and other preparation processes were the same as in Example 1. Example 6 Xanthan gum is not added in step (5), and other preparation processes are the ...

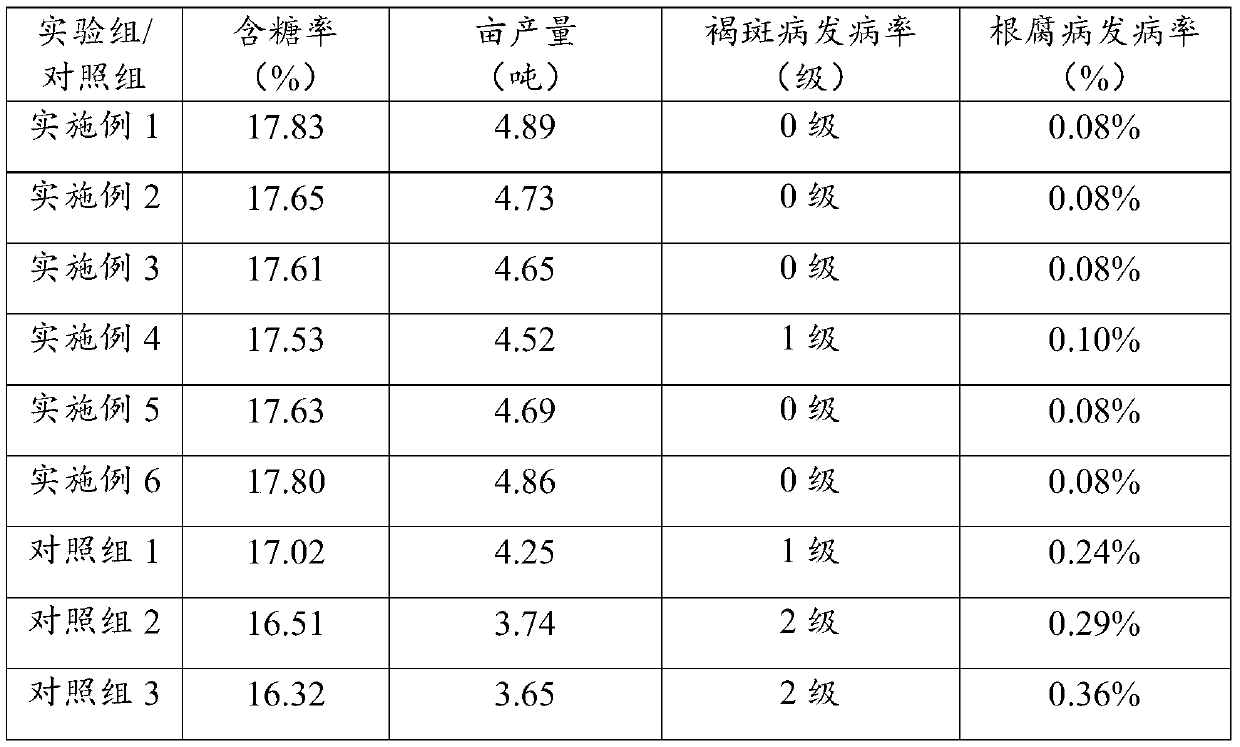

experiment example

[0074] 1. The purpose of the experiment

[0075] Using the yeast concentrate liquid fertilizer for sugar beet prepared in the embodiment of the present invention, field experiments were conducted at the Baihuisheng R&D Center Experimental Base of Linxi County, Chifeng City, Inner Mongolia, to identify the effect of the liquid fertilizer on sugar beet, yield and disease resistance.

[0076] 2. Overview of the experiment

[0077] The field management of the test field was carried out in accordance with standardization, including planting and transplanting, drip irrigation under the film, and timely prevention of diseases, insects and weeds. The sugar beet variety is Syngenta HI0936, the beet spacing is 26cm, the row spacing is 50cm, and 5000 seedlings are protected per mu.

[0078] 3. Experimental design

[0079] In this experiment example, the experimental group and the control group are set, and each group is set to repeat the experiment three times. The setting method is as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com