Steel slag selecting method

A steel slag and magnetic separation technology, applied in solid separation, recycling technology, mechanical material recovery and other directions, can solve problems such as environmental pollution, and achieve the effect of solving environmental protection pressure, realizing maximization, and realizing the utilization of steel slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

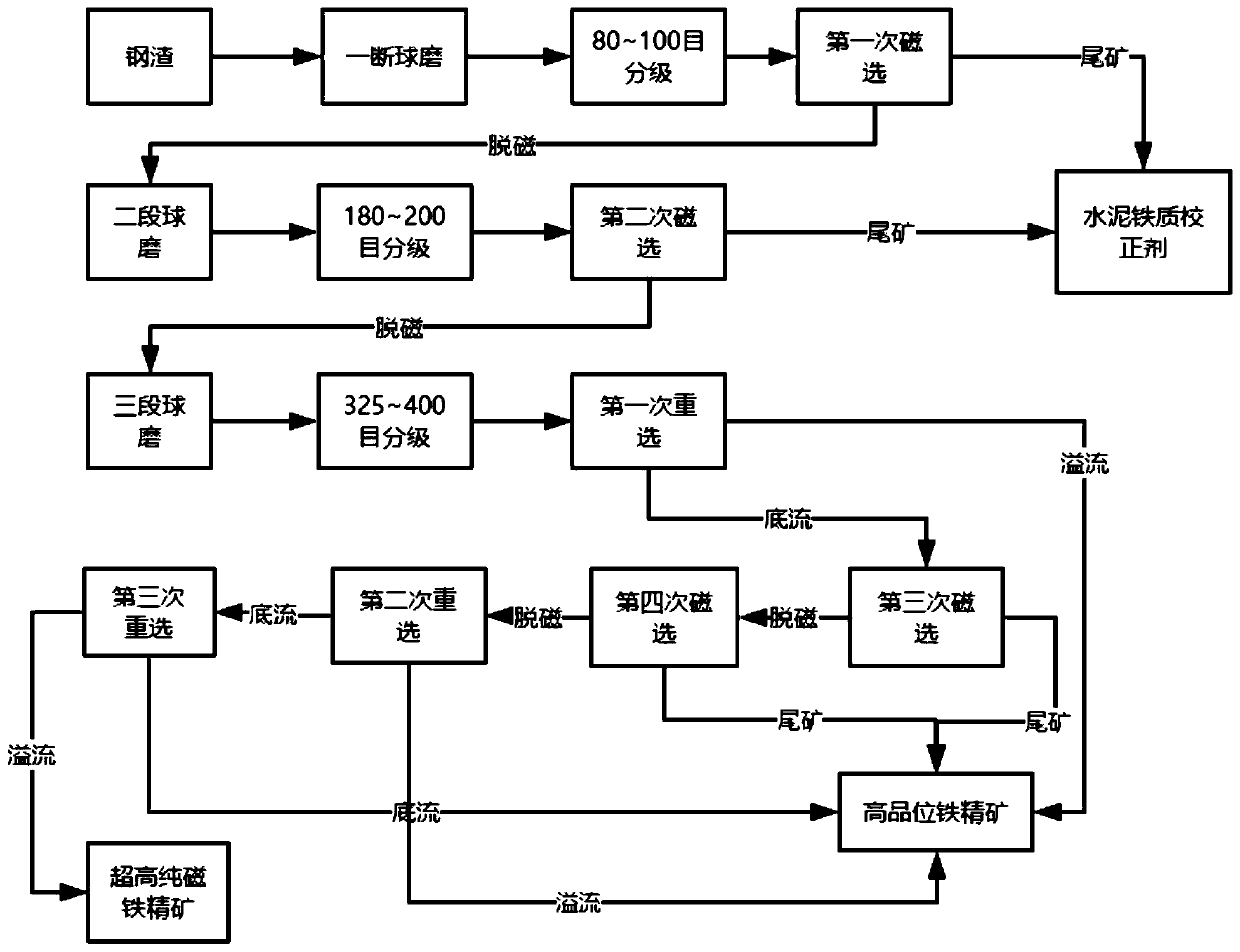

[0038] Such as figure 1 As shown, a kind of steel slag sorting method for cement iron correction agent is provided, comprising the following steps:

[0039] Step 1: Carry out the first stage of ball milling steel slag until the particle size of steel slag exceeds 100 mesh, and then perform the first magnetic separation to obtain a magnetically separated concentrate and tailings for future use; The abrasive after ball milling enters the high weir type spiral classifier for classification, and the unqualified particle size (>100 mesh) steel slag classified by the high weir type spiral classifier is returned to the first stage of ball mill to continue ball milling, and repeated cycles until the graded mineral material particle size If the particle size is less than 100 mesh, the first magnetic separation will be performed on the ore with a particle size of less than 100 mesh after classification. The magnetic field strength of the first magnetic separation is 850±50GS. The tailin...

Embodiment 2

[0041] A method for sorting steel slag, specifically comprising the following steps:

[0042] Step 1: Carry out the first stage of ball milling steel slag until the particle size of steel slag exceeds 80 meshes, and then perform the first magnetic separation to obtain a magnetically separated concentrate and tailings for use; The abrasive after ball milling enters the high weir type spiral classifier for classification, and the steel slag with unqualified particle size (>80 mesh) classified by the high weir type spiral classifier enters the first stage of ball mill to continue ball milling, and repeats the cycle until the graded mineral material particle size If it is less than 80 mesh, the first magnetic separation will be performed on the ore with a particle size of less than 80 mesh after classification. The magnetic field strength of the first magnetic separation is 850±50GS, and the magnetic separation will obtain a magnetic separation concentrate and tailings. The tailing...

Embodiment 3

[0045] The present embodiment provides a kind of sorting method of steel slag, specifically comprises the following steps:

[0046] Step 1: Carry out the first stage of ball milling steel slag until the particle size of steel slag exceeds 90 meshes, and then perform the first magnetic separation to obtain a magnetically separated concentrate and tailings for use; The abrasive after ball milling enters the high weir type spiral classifier for classification, and the steel slag with unqualified particle size (>90 mesh) classified by the high weir type spiral classifier enters the first stage of ball mill to continue ball milling, and repeats the cycle until the graded mineral material particle size If it is less than 90 mesh, the first magnetic separation will be performed on the ore with a particle size of less than 90 mesh after classification. The magnetic field strength of the magnetic separation is 850±50GS, and the magnetic separation will obtain the primary magnetic separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com