Ferromagnetic glass fiber, preparation method, and application of same

A glass fiber and ferromagnetic technology, applied in glass manufacturing equipment, inorganic material magnetism, manufacturing tools and other directions, can solve the problems of complex glass batch preparation method, low magnetic glass fiber output, unsuitable for industrial production, etc., to solve environmental problems. Pressure and occupation of land resources, considerable economic and social benefits, and the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A ferromagnetic glass fiber, based on the preparation of 500kg of batch material, according to the following mass proportions:

[0045]

[0046] The preparation steps are as follows:

[0047] Add the above batch materials into the glass furnace, melt, clarify and homogenize at 1460°C according to the conventional melting conditions, and flow to the bushing when it is cooled to about 1180°C through the feeding channel, and use traditional glass fiber drawing Technology drawn into ferromagnetic glass fibers.

[0048]The chemical composition of the ferromagnetic glass fiber that present embodiment makes is as follows, is mass percent:

[0049] Fe 2 o 3 : 40.02%, SiO 2 : 35.01%, Al 2 o 3 : 5.94%, B 3 o 3 : 4.03%, CaO: 11.89%, MgO: 3.11%.

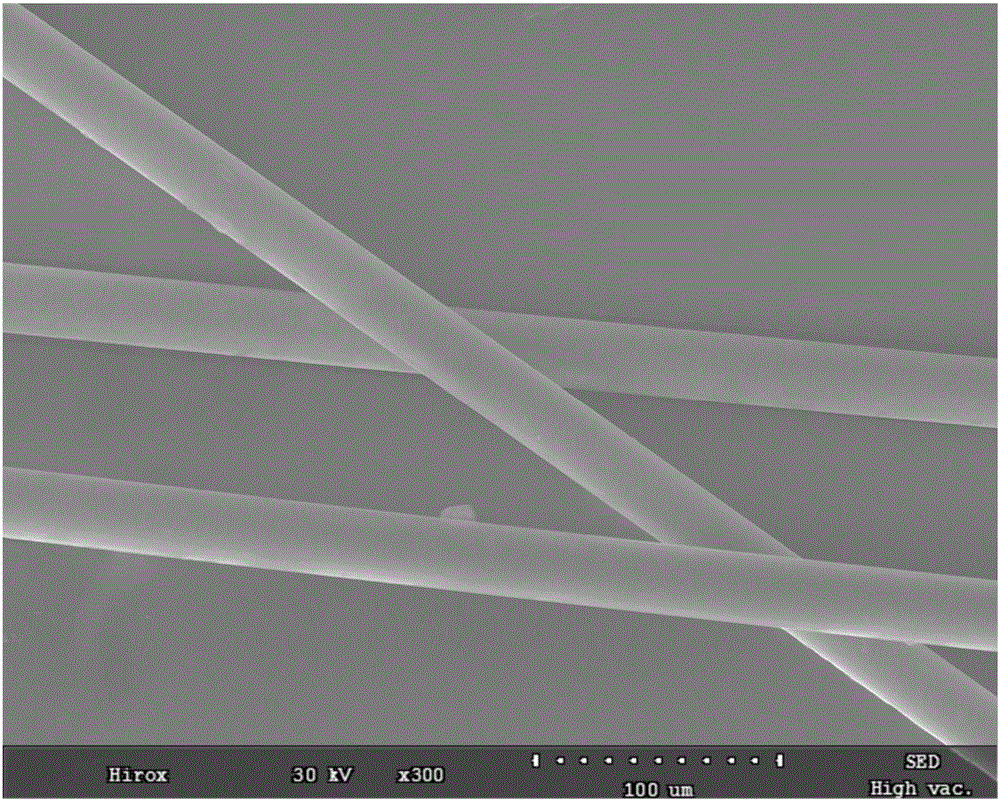

[0050] The scanning electron microscope picture of the ferromagnetic glass fiber that present embodiment makes is as figure 1 shown by figure 1 It can be seen that the average diameter of the ferromagnetic glass fibers prepa...

Embodiment 2

[0055] A ferromagnetic glass fiber, based on the preparation of 500.01kg of batch material, according to the following mass proportions:

[0056]

[0057] The preparation steps are the same as in Example 1.

[0058] The chemical composition of the ferromagnetic glass fiber that present embodiment makes is as follows, is mass percent:

[0059] Fe 2 o 3 : 41.86%, SiO 2 : 33.01%, Al 2 o 3 : 5.97%, B 3 o 3 : 3.98%, CaO: 12.02%, MgO: 3.03%.

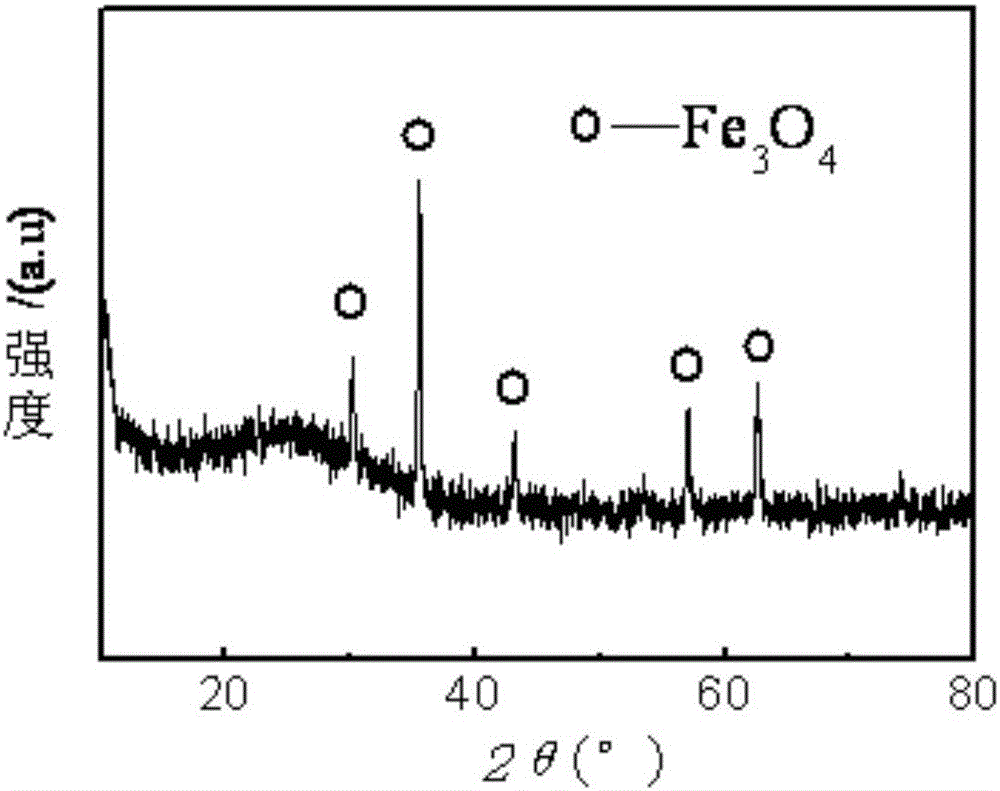

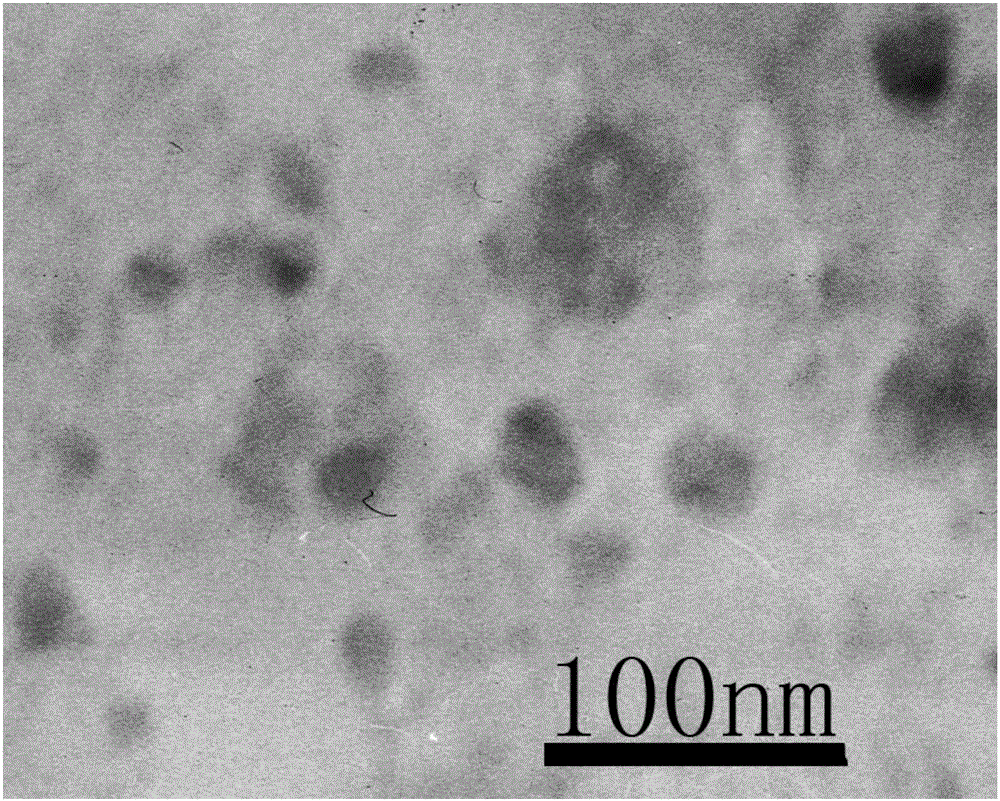

[0060] The crystalline phase of the ferromagnetic glass fiber that present embodiment makes is Fe 3 o 4 Crystal, the crystal size is 25nm;

[0061] The ferromagnetic glass fiber has a diameter of 20 μm and a specific saturation magnetic moment of 12 emu / g.

Embodiment 3-8

[0063] The raw material ratio of embodiment 3-8 is as shown in table 1.

[0064] Table 1

[0065] Raw material\Example

Example 3

Example 4

Example 5

Example 6

Example 7

Example 8

Pyrite slag (kg)

301.74

288.79

282.27

275.68

269.06

262.40

Quartz sand (kg)

69.87

80.24

85.46

90.75

96.02

101.35

16.65

17.06

17.23

17.44

17.65

17.86

Limestone (kg)

53.10

53.47

53.68

53.88

54.08

54.26

Dolomite (kg)

31.34

32.96

33.80

34.61

35.46

36.32

Boric acid (kg)

27.30

27.47

27.56

27.64

27.73

27.81

total

500.00

499.99

500.00

500.00

500.00

500.00

[0066] The preparation steps are the same as in Example 1.

[0067] The chemical composition of the ferromagnetic glass fiber that embodiment 3-8 makes is as shown in table 2, is mass percent:

[0068] Table 2

[0069]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com