Wave-absorbing functional protecting coating on surface of aluminum alloy and preparation method thereof

A technology of aluminum alloy surface and protective coating, applied in the field of aluminum alloy, can solve problems such as personal safety and equipment stability impact, achieve great social and economic value, change the absorption intensity and absorption peak frequency range, and electromagnetic wave absorption frequency is wide. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Use aluminum alloy plate, here choose LY12 aluminum alloy for processing. Place the aluminum alloy surface to be processed in the electrolyte. Described electrolytic solution comprises the sodium silicate that concentration is 5~30g / L (this embodiment is 30g / L), the sodium hydroxide that concentration is 1~10g / L (this embodiment is 5g / L), concentration is 1 ~5g / L (the present embodiment is 5g / L) urea, the rest is water. The surface of the alloy to be processed is used as an electrode, the inert conductor is used as a counter electrode of the surface of the alloy to be processed, and the above two electrodes and a power supply form an electrolytic circuit. The inert conductor mentioned here is a conductor (graphite in this embodiment) that is inert to the specific electrolyte solution in this embodiment.

[0035] The control power supply applies a DC or AC pulse voltage, and the pulse frequency is adjusted within the range of 20-3000 Hz (1000 Hz in this embodim...

Embodiment 2

[0042] Step 1: Carry out the same steps as Step 1 of Example 1.

[0043] Step 2: Mix barium titanate:epoxy resin at a mass ratio of 55:45, the particle size of the wave absorbing agent is 50-100nm, heat up to 80°C, and stir to make it uniformly dispersed.

[0044] Step 3: In the coating prepared in step 2, add curing agent polyamide (mass ratio to epoxy resin is 1: 2), evenly coat the ceramic layer prepared in step 1 and dry, with a thickness of 1 or 2mm, The curing temperature is 70°C, and the curing time is 6 hours.

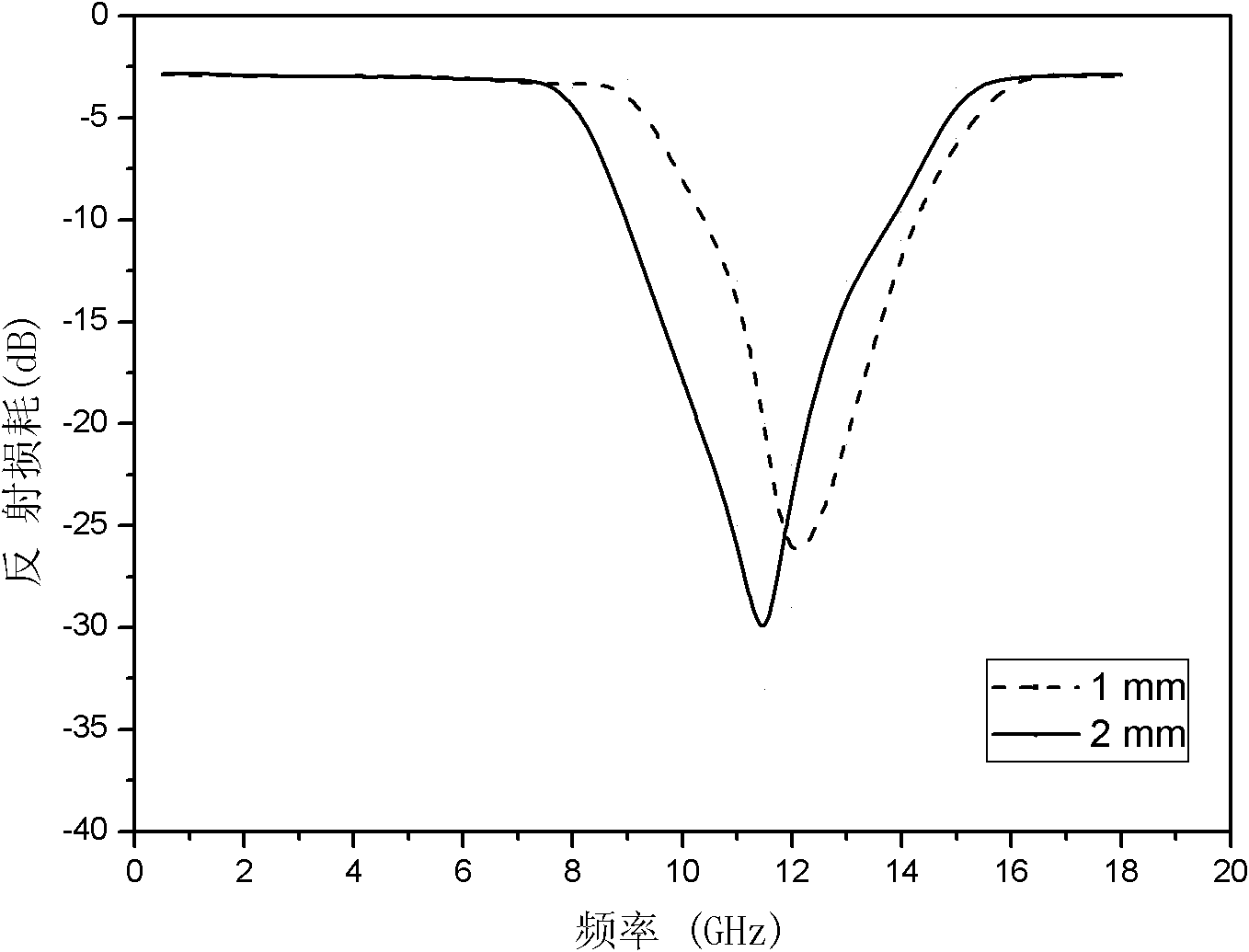

[0045] The neutral salt spray resistance time (ASTM B117 standard) of the coating sample coated with aluminum alloy is ≥6000h, and the absorption curve is as follows image 3 , it can be seen from the figure that when the coating thickness is 1mm, the reflection loss of electromagnetic waves between 11 and 14GHz is less than -10dB, the absorption bandwidth is 3GHz, and the absorption peak is -27dB; when the coating thickness is 2mm, the electromagnetic wave is...

Embodiment 3

[0047] Step 1: Carry out the same steps as Step 1 of Example 1.

[0048] Step 2: Mix carbonyl iron powder: epoxy resin at a mass ratio of 70:30, the particle size of the wave absorbing agent is 50-100nm, heat up to 80°C, and stir to make it uniformly dispersed.

[0049] Step 3: In the coating prepared in step 2, add curing agent polyamide (mass ratio to epoxy resin is 1: 2), evenly coat the ceramic layer prepared in step 1 and dry, with a thickness of 1 or 2mm, The curing temperature is 70°C, and the curing time is 6 hours.

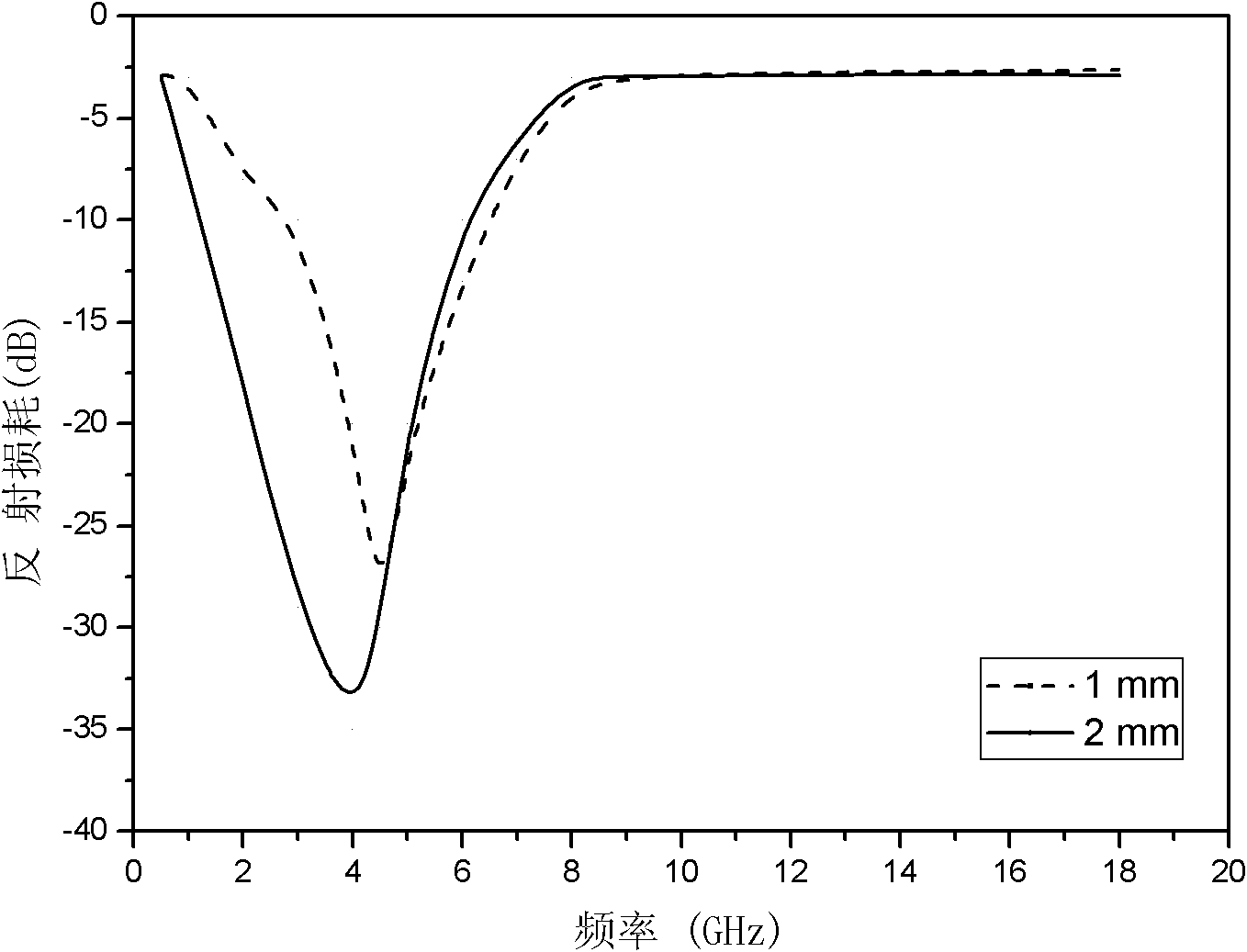

[0050] Aluminum alloy coated with this coating sample has a neutral salt spray resistance time (ASTM B117 standard) ≥ 5500h, and the absorption curve is as follows Figure 4 , it can be seen from the figure that when the coating thickness is 1mm, the reflection loss of the electromagnetic wave between 4.5 and 7.5GHz is less than -10dB, the absorption bandwidth is 3GHz, and the absorption peak is -29dB; when the coating thickness is 2mm, the electromagnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com