Equipment and method for crushing and sorting solar cell components

A solar cell module and sorting technology, which is applied in the direction of electronic waste recycling, solid waste removal, recycling technology, etc., can solve problems such as easy generation of waste water and waste gas, difficult disassembly and classification of solar cell components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

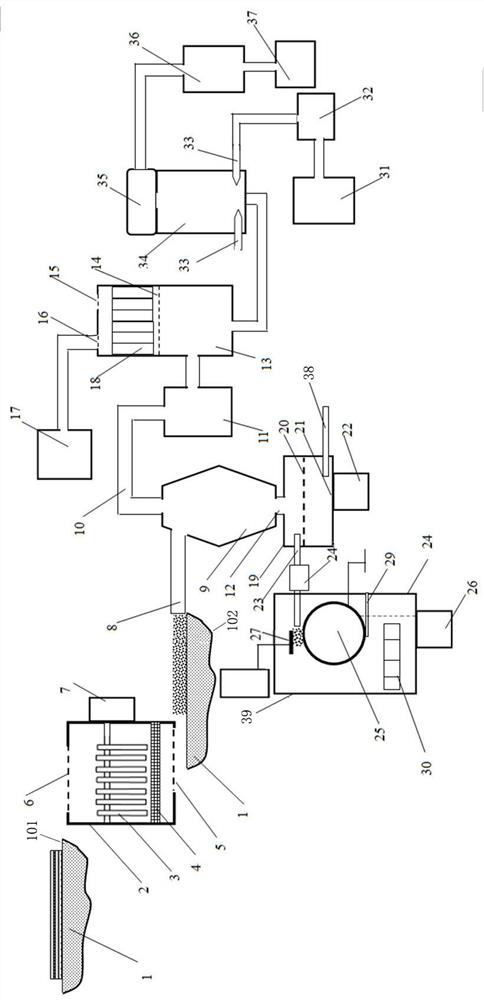

[0046] Such as figure 1 As shown, the equipment of the present invention includes a first feeding device 101, a hammer crushing and splitting device, a second feeding device 102, a wind separation device, a vibration screening device, an electrostatic separation device and an air flow crushing and grading device.

[0047] The hammering and splitting device includes a hammering chamber 2, a hammering mechanism 3 arranged in the hammering chamber 2, a discharge screen 4 arranged below the hammering mechanism 3, and a hammering mechanism for driving the hammering mechanism 3. motor7. There is a hammering inlet 6 on the upper side of the cavity, and a hammering outlet 5 on the lower side of the discharge screen 4 of the cavity. The hammering mechanism 3 includes a rotating shaft and 5-20 hammers arranged on the rotating shaft. One end of the hammers is evenly arranged coaxially along the rotating shaft. The hammering motor 7 controls the rotating shaft to drive the hammers to rot...

Embodiment 2

[0054] The method for crushing and sorting solar cell components of the present invention comprises the following steps:

[0055] a. Prepare the equipment for crushing and sorting solar cell assemblies described in Example 1, and send the solar cell assemblies without the aluminum frame and glass to the hammering and dismantling device.

[0056] b. The hammering motor 7 of the hammering and splitting device drives the hammer blade of the hammering mechanism 3 to rotate, and the hammer blade crushes the solar battery module, the plastic of the module is hammered into plastic particles, and the battery sheet of the module is hammered into silicon particles and Metal welding strip particles, metal converging belt particles, these particles form a particle mixture; the particle mixture smaller than the 4 meshes of the discharge screen is sieved out through the screen mesh, and sent to the second feeding device 102 through the hammering discharge port, Sent to the winnowing separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com