Pig feed additive and preparation method and application thereof

A feed additive and feed technology, applied in the direction of bacteria, application, animal feed, etc. used in food preparation, can solve the problems of increasing the rate of survival and slaughter, and achieve the effects of increasing the rate of survival and slaughter, improving immunity, and enhancing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

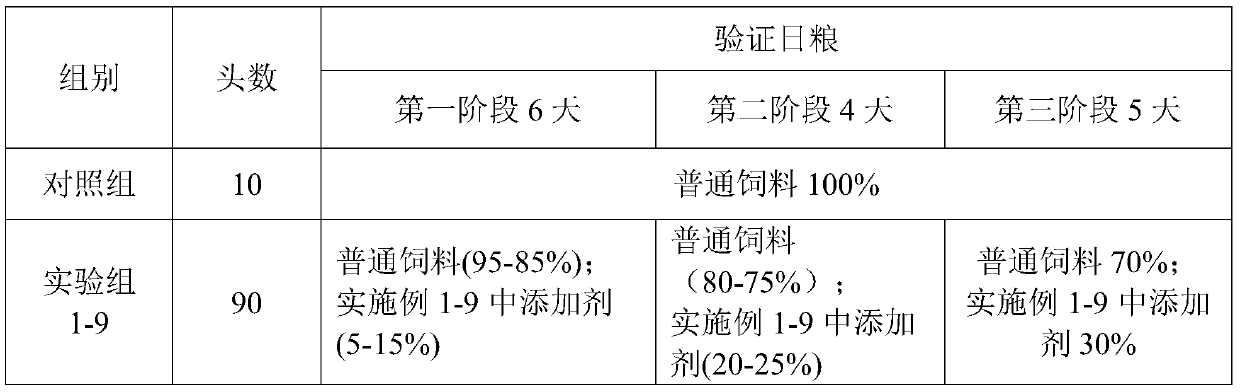

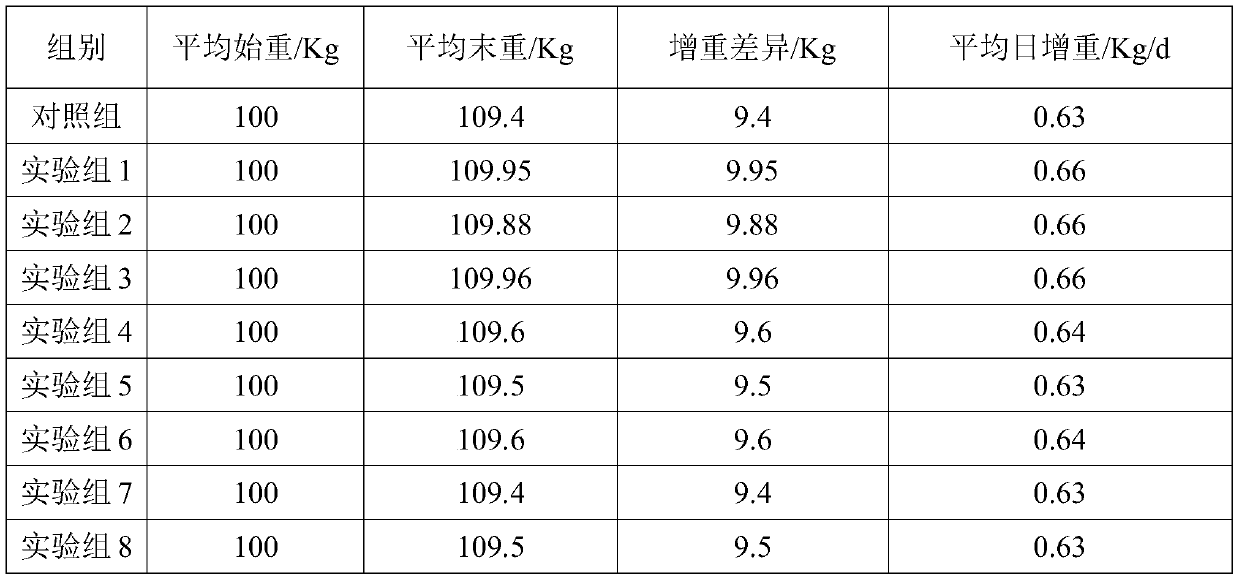

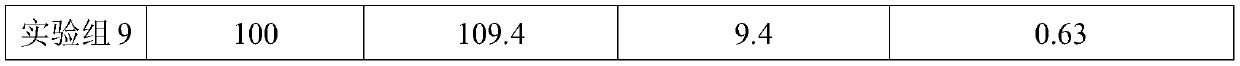

Method used

Image

Examples

Embodiment 1

[0054] The present embodiment provides a kind of pig feed additive, and its preparation method is as follows:

[0055] (1) Co-cultivate the mixed flora comprising Lactobacillus acid-fast and Lactobacillus branii in equal proportions for 36 hours at 40°C to obtain a fermentation inoculant;

[0056] (2) Grinding the dry yellow corn stalks produced in the current year to a particle size of 6 mm, and sieving to obtain a standard fermented product;

[0057] (3) Mix the fermented inoculant obtained in step (1) with water and incubate at 37°C for 24 hours to activate it, and mix it with the standard fermented product obtained in step (2) and fermentation auxiliary materials corn flour, 5-aminolevulinic acid, salt , glucose, and cellulase were mixed, and facultative anaerobic fermentation was carried out at 25° C. for 7 days to obtain the pig feed additive. Wherein the ratio of the standard fermented substance to the volume of the fermentation inoculum is 2kg / mL; the mass ratio of th...

Embodiment 2

[0059] The present embodiment provides a kind of pig feed additive, and its preparation method is as follows:

[0060] (1) Co-cultivate the mixed flora containing Lactobacillus acidophilus, Lactobacillus acidophilus, Lactobacillus brinneri, and Lactobacillus fermentum at 50°C for 24 hours to obtain a fermentation inoculant; wherein the total amount of Lactobacillus acidophilus and Lactobacillus acidophilus The ratio of the mass to the total mass of Lactobacillus Brucella and Lactobacillus fermentum is 2:3;

[0061] (2) Grinding the dry yellow corn stalks produced in the current year to a particle size of 5 mm, and sieving to obtain a standard fermented product;

[0062] (3) Mix the fermented inoculant obtained in step (1) with water and incubate at 35° C. for 30 h to activate it, and mix it with the standard fermented product obtained in step (2) and fermentation auxiliary corn flour, 5-aminolevulinic acid, vitamin and glucose were mixed, and facultative anaerobic fermentatio...

Embodiment 3

[0064] The present embodiment provides a kind of pig feed additive, and its preparation method is as follows:

[0065] (1) Co-cultivate the mixed flora containing Lactobacillus acid-resistant, Lactobacillus acidophilus, Lactobacillus brinneri, Lactobacillus fermentum, Trichoderma longifera, and Aspergillus oryzae at 30°C for 72 hours to obtain a fermentation inoculant; wherein the acid-resistant The ratio of the total mass of Lactobacillus and Lactobacillus acidophilus to the total mass of Lactobacillus Brucella and Lactobacillus fermentum is 3:2;

[0066] (2) Grinding the dry yellow corn stalks produced in the current year to a particle size of 8mm, and sieving to obtain a standard fermented product;

[0067] (3) Mix the fermented inoculant obtained in step (1) with water and incubate at 40°C for 20 hours to activate it, and mix it with the standard fermented product obtained in step (2) and fermentation auxiliary materials corn flour, 5-aminolevulinic acid, vitamin , glucos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com