A kind of Florfenicol intermediate, its preparation method and the preparation method of Florfenicol

A technology for florfenicol and intermediates, which is applied in the field of intermediates for preparing florfenicol, can solve the problems of long process, difficult industrial production, low yield and the like, and achieves high environmental protection pressure, easy operation and high yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

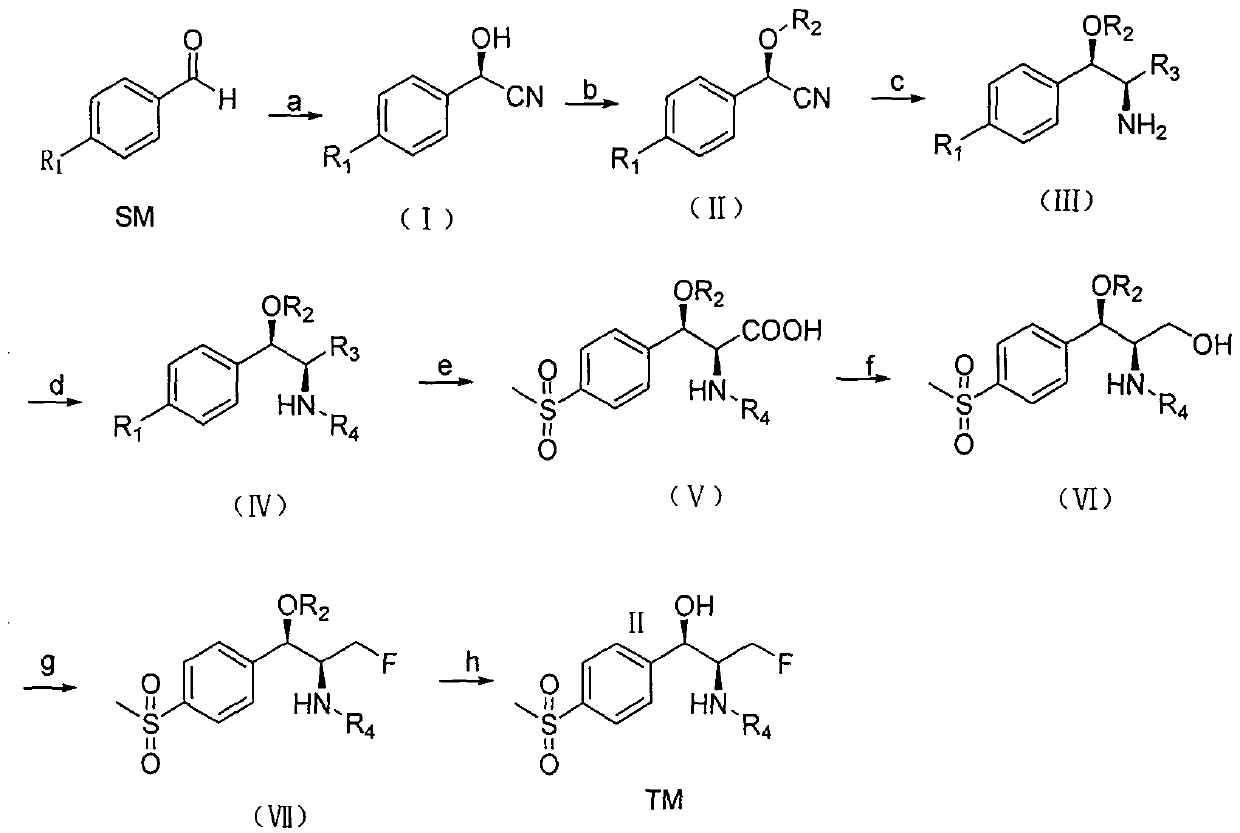

Method used

Image

Examples

Embodiment I

[0062]

[0063]KCN (307 g, 4.71 mol) was added into a buffer solution prepared with citric acid (400 mL, pH=5.0), cooled to 0° C., and set aside. Dissolve p-methyl sulfide benzaldehyde (71.6 g, 0.471 mol) in TBME (400 mL), add to the reaction solution, maintain 0 °C, add (R)-HNL (40 mL), stir for 1.5 hours, and HPLC detects that the reaction is complete. 5M HCl (50 mL) was added to quench the reaction, the catalyst precipitated, filtered, the filtrate was extracted with DCM (3×50 mL), the organic phases were combined, dried and concentrated to give compound I (83.1 g, 98.6%).

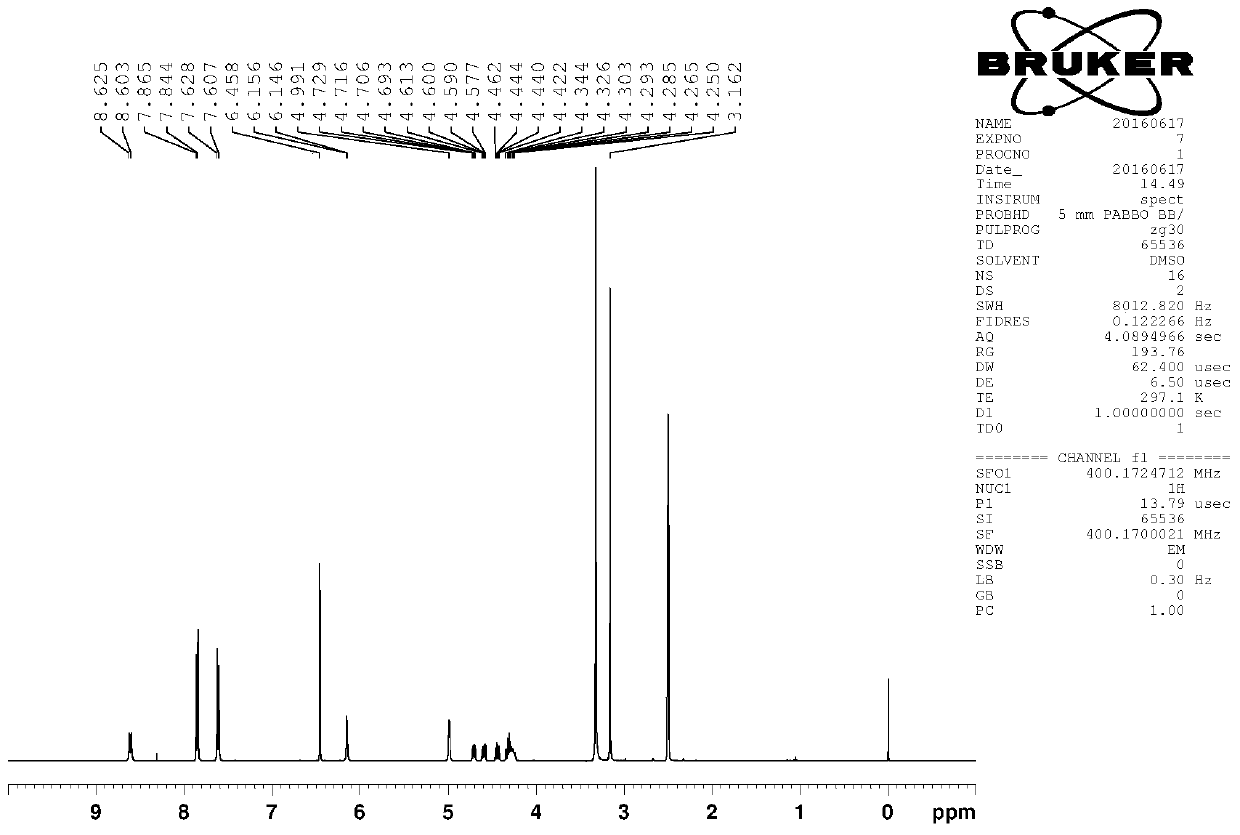

[0064] 1 H NMR (CDCl 3 300MHz): δ2.5(s, 3H), 3.0(br, s, 1H), 5.49(s, 1H), 7.29-7.43(AB, J=8.5Hz, 4H).

Embodiment II

[0066]

[0067] Compound I (10 g, 55.8 mmol) was dissolved in CH 3 CN (150mL), add methylal (12.5g, 167.4mmol), add P 2 o 5 (23.5g, 167.4mmol), TLC detection until the end of the reaction. Pour the reaction solution into water, remove acetonitrile under reduced pressure, add TBME (100mL×2) for extraction, combine the organic phases, and wash with saturated NaHCO 3 (100ml×1), washed with saturated NaCl solution (500mL×1), dried over anhydrous sodium sulfate, concentrated by suction filtration to obtain compound IIa (12.4g, 83.2%).

[0068] Dissolve p-methyl sulfide benzaldehyde (10g, 65.7mmol) in THF (70mL), add zinc bromide (1.5g, 6.57mmol), drop the temperature to 0-5°C under the protection of nitrogen, then add dropwise TMSCN (6.5 g, 6.57mmol), reacted for 25hs, and HPLC detected the end of the reaction. Pour the reaction solution into water, add TBME (100mL×2) for extraction, combine the organic phases, and wash with saturated NaHSO 3 (100ml×1), washed with saturate...

Embodiment III

[0071]

[0072] Compound IIa (5.0g, 22.4mmol) was dissolved in 100mL ether, cooled to 0°C, vinylmagnesium bromide (24mL, 67.2mmol) was added dropwise, stirred at this temperature for 1 hour, and methanol was added after the disappearance of the raw material was detected by HPLC (70mL), added sodium borohydride (3.4g, 89.6mmol) in batches, stirred for 1.5 hours, HPLC detected that the reaction was over, added ice water to quench, extracted with TBME (50mL×2), after combining the organic phases, washed with water (50mL ×2), washed with saturated sodium chloride (50mL×2), dried and concentrated to obtain a crude product (6.8g), which was recrystallized by EA / PE system to obtain compound IIIa (5.4g, 95%) as a white solid.

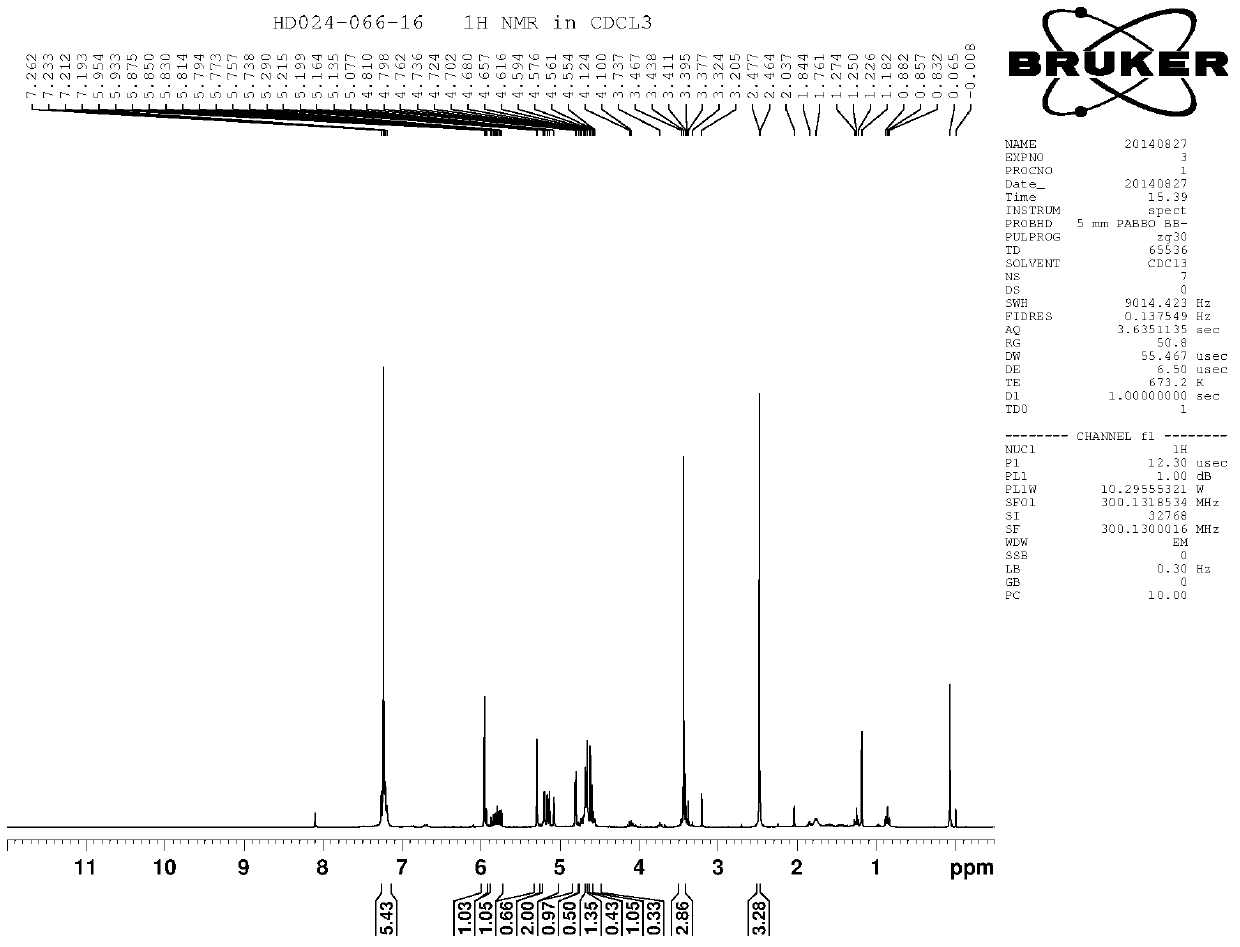

[0073] 1,3-Dithiane (0.48g, 3.99mmol) was added into ether (20mL), cooled to -78°C, n-butyllithium (2.5mL, 3.99mmol) was added dropwise, and after stirring for 30min, compound IIb (0.5 g, 1.98mmol) in ether solution, reacted at -78°C for 1.5hs, added methano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com