Preparation method of hydroxyl apatite and application of hydroxyl apatite in 3D printing moulding

A technology of hydroxyapatite and 3D printing, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of undiscovered hydroxyapatite material research, and achieve low cost, simple process flow, and chemical reaction easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, a preparation and molding process of hydroxyapatite powder that can be used for 3D printing:

[0043]1), at room temperature, weigh 49.11g (0.334mol) of calcium chloride dihydrate and 14.19g (0.1mol) of phosphorus pentoxide, respectively dissolve them in 200ml of deionized water and 200ml of absolute ethanol, and stir for 2 hours respectively;

[0044] 2), take 50ml of calcium chloride aqueous solution in step 1) and stir in a beaker, and take 50ml of phosphorus pentoxide alcohol solution with a syringe, slowly drop into the beaker (dropping time is 2 minutes), and stir at room temperature for 2h;

[0045] 3) Place the mixed solution obtained in step 2) in a 60°C oven for aging for 48 hours;

[0046] In the above aging process, the mixed solution is placed in an open container, and the opening of the container is sealed with a plastic wrap, and some small holes are set on the plastic wrap to facilitate the discharge of volatile gas; after the aging is comp...

Embodiment 2

[0063] Example 2, a preparation and molding process of hydroxyapatite powder that can be used for 3D printing

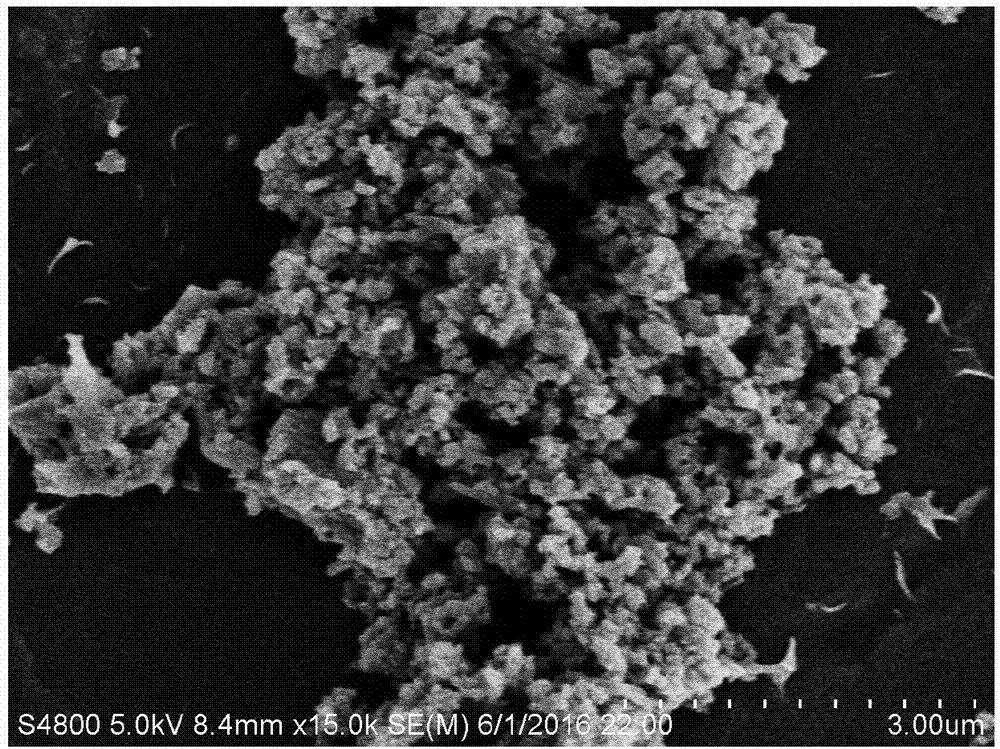

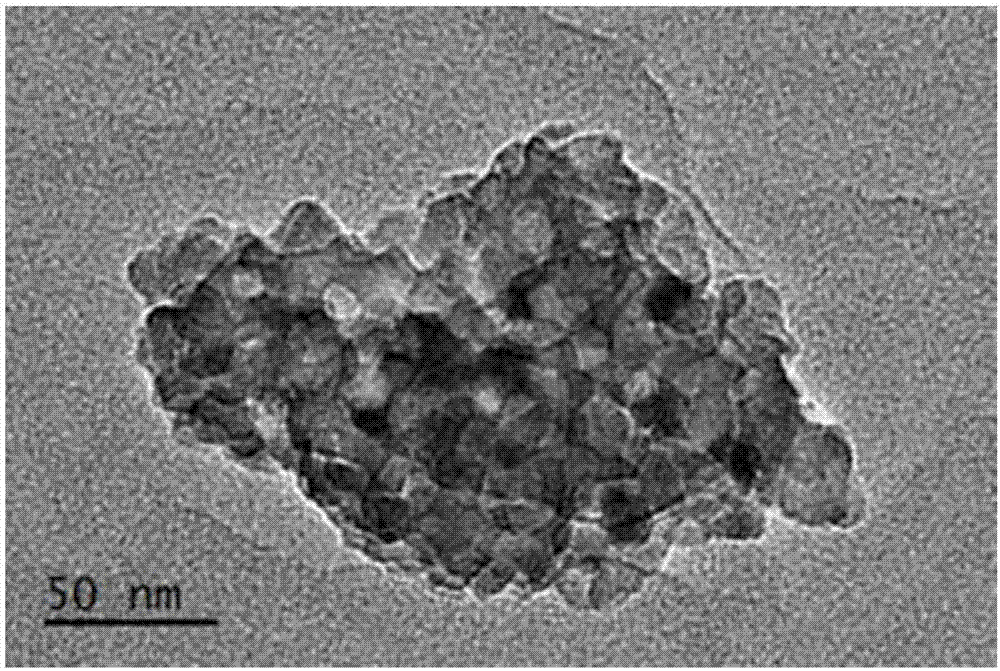

[0064] Change the heat treatment temperature in Step 5) of Example 1 from 800°C to 600°C, and the rest are the same as in Example 1. The prepared main crystal phase is still hydroxyapatite with a high degree of crystallinity. The observation results under the transmission electron microscope are as follows: image 3 As shown, granular nano-hydroxyapatite grains were obtained, and the grain diameter was about 20 nm.

[0065] Comparative Example 2-1. The heat treatment temperature in Example 2 was changed from 600°C to 500°C, and the rest were the same as in Example 2.

[0066] Comparative Example 2-2, the heat treatment temperature in Example 2 was changed from 600°C to 700°C, and the rest were the same as in Example 2.

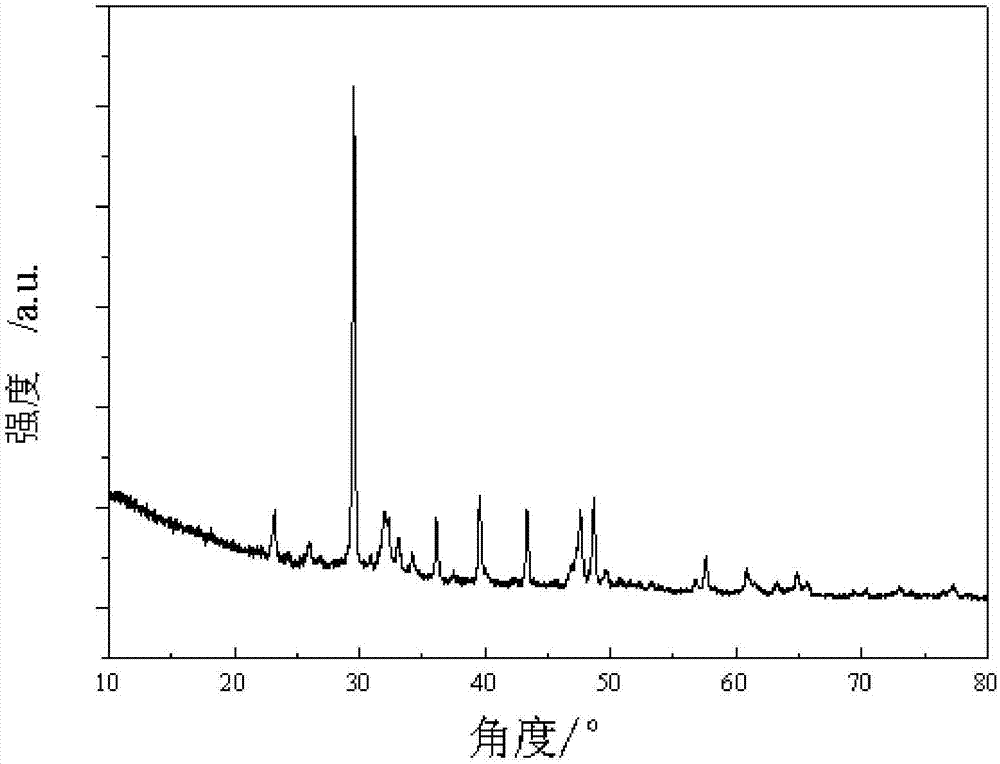

[0067] By X-ray diffraction, the law of the phase change with the heat treatment temperature was analyzed, and the results were as follows: Fig...

Embodiment 3

[0071] Example 3, a preparation and molding process of hydroxyapatite powder that can be used for 3D printing

[0072] The total mass of hydroxyapatite fine powder added in Step 7 of Example 1 was changed from 7.5 g to 8 g, and the rest were the same as in Example 1.

[0073] The compressive strength of the final printed hydroxyapatite 3D model was measured to be 7.53MPa. It can be seen that with the increase of the mass ratio of powder in the slurry, the strength of the printed product is slightly improved. This is a consequence of the decrease in porosity in the model as the solids content increases.

[0074] Comparative Example 3-1. The total mass of hydroxyapatite fine powder added in Example 3 was changed from 8g to 6g, and the rest were the same as in Example 3. Due to the low solid content, the viscosity of the slurry is not enough to achieve molding during the printing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com