Fireproof protection and decoration integrated structure on steel member

A technology for steel components and decoration, applied in fire prevention, building components, building structures, etc., can solve the problems of heat resistance, non-fire resistance, easy corrosion, high cost, and achieve the effect of clean and tidy construction environment, easy organization, and single specification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

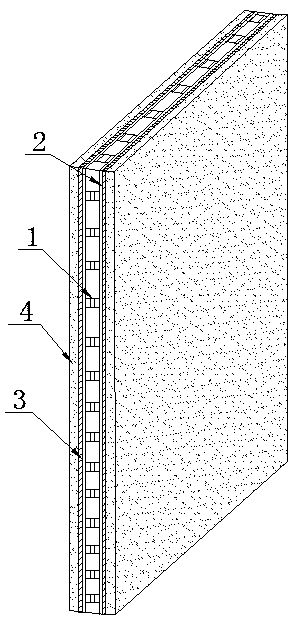

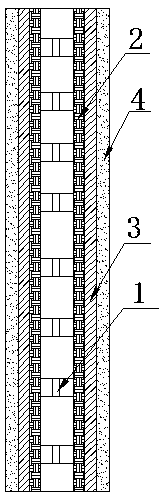

[0032] An integrated structure for fire prevention protection and decoration on a steel component, the thickness of the wall sprayed mortar is 35 mm, including a steel component 1, a steel structure interface mortar layer 2, a steel wire mesh 3 and a wall sprayed mortar layer 4; the steel component 1 is the load-bearing structure of a steel structure building; the steel structure interface mortar layer 2 is applied to the front and back of the steel member 1; the steel wire mesh 3 is laid on the surface of the steel structure interface mortar layer 2; the steel wire mesh 3 The surface of the wall is sprayed with a wall sprayed mortar layer 4, and the wall sprayed mortar layer 4 completely wraps the steel member 1, the steel structure interface mortar layer 2 and the steel wire mesh 3, forming a 35mm thick fire protection and decoration. layer.

[0033] Further, the construction sequence is characterized by: installing steel components → installing steel wire mesh on the steel ...

Embodiment 2

[0041] An integrated structure for fire protection, protection and decoration on steel components, the thickness of wall sprayed mortar is 20mm, including steel component 1, steel structure interface mortar layer 2, glass fiber mesh cloth 3 and wall sprayed mortar layer 4; The steel component 1 is a load-bearing structure of a steel structure building; the steel structure interface mortar layer 2 is applied to the front and back of the steel component 1; the glass fiber mesh cloth 3 is laid on the surface of the steel structure interface mortar layer 2 The surface of the glass fiber mesh cloth 3 is sprayed with a wall sprayed mortar layer 4, and the wall sprayed mortar layer 4 completely wraps the steel member 1, the steel structure interface mortar layer 2 and the glass fiber mesh cloth 3 In the process, a 20mm thick fire protection and decoration integrated layer is formed.

[0042] Further, install the steel components → scrape the mortar layer at the interface of the steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com