Bio-based dimer fatty acid base vinyl ester resin as well as preparation method and application thereof

A bio-based dimerized fatty acid-based vinyl ester technology is applied in the field of preparing dimerized fatty acid-based vinyl ester resin, which can solve the problems of high price of epoxy resin, limited wide application and the like, and achieves mild reaction conditions, simple process, The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

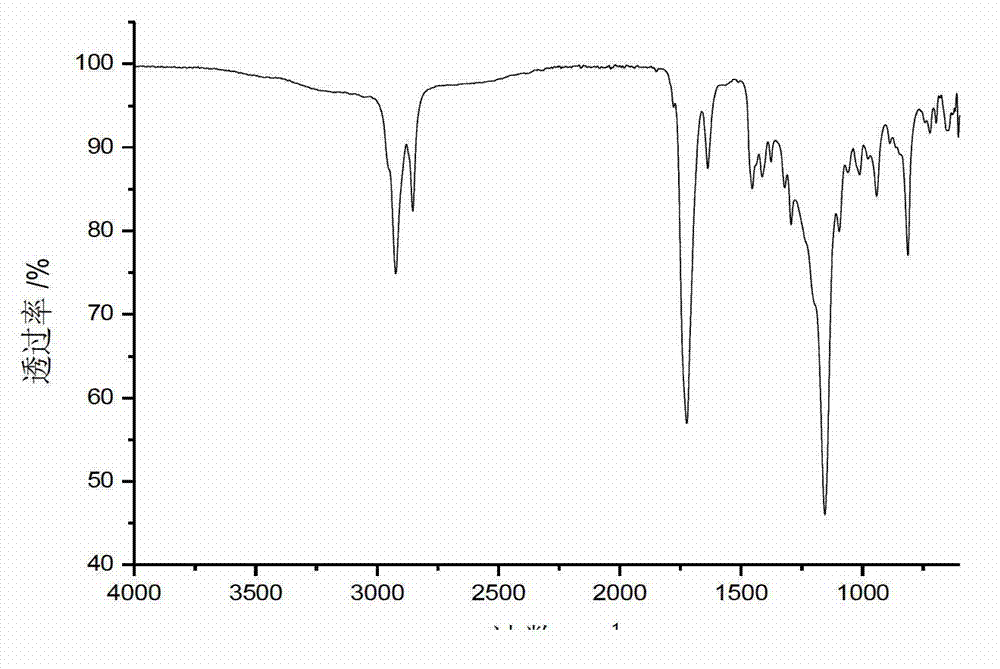

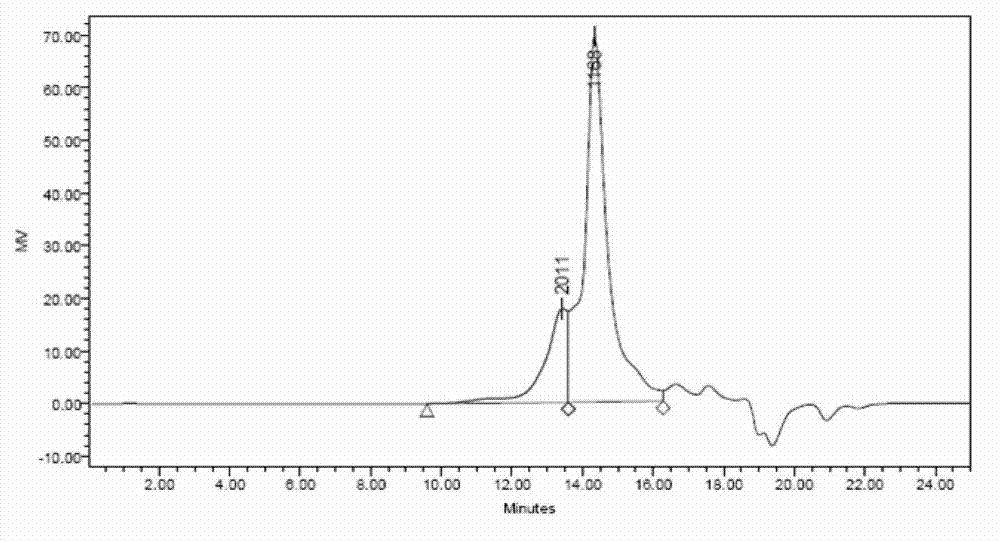

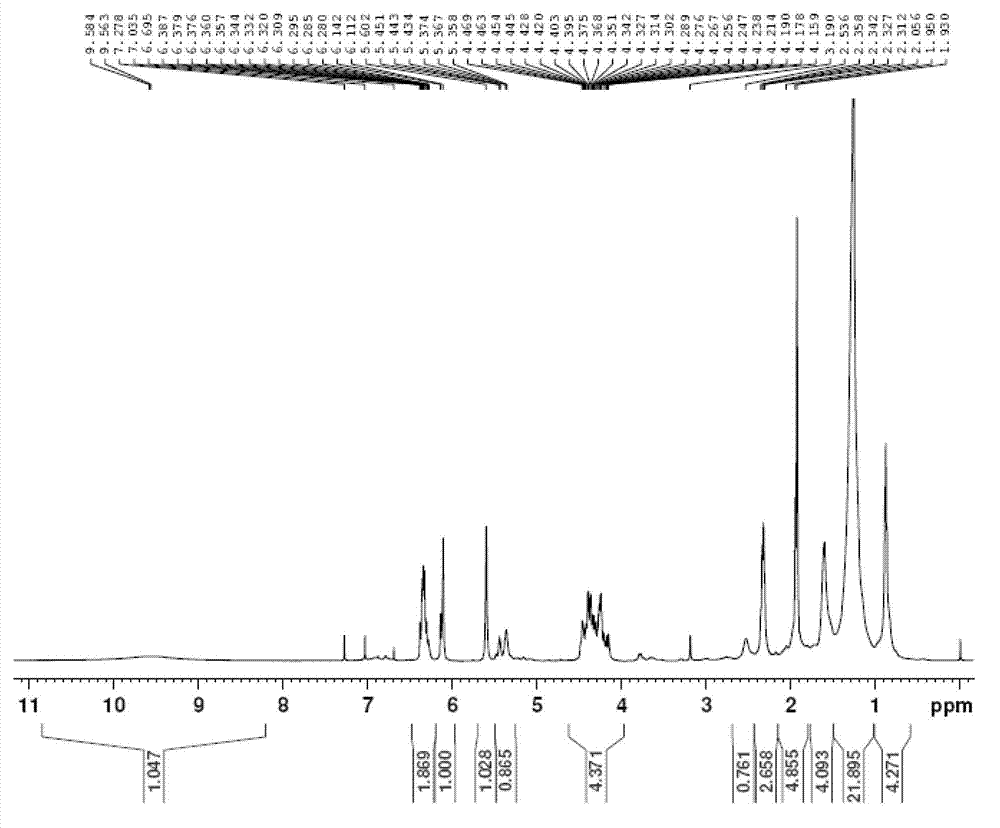

[0038] Under a nitrogen atmosphere, put a certain amount of dimer fatty acid in a reaction flask, stir and heat to 65°C, add glycidyl methacrylate dropwise at a molar ratio of 1.75:1 to dimer fatty acid; The total mass of 0.05% of 2-tert-butylhydroquinone was added to the total mass of 2.5% of tetramethylammonium chloride, and then heated to 110 ° C, refluxed for 6 hours to obtain the intermediate product dimer fatty acid unsaturated diglyceride Then the system is properly cooled to 70°C, and acrylic anhydride is added at a ratio of 1.75:1 to the dimer fatty acid molar ratio, refluxed for 4 hours, and finally the dimer fatty acid-based vinyl ester resin monomer is obtained by activated carbon decolorization; The prepared resin monomer and ethyl acrylate monomer were mixed in a mass ratio of 100:80, stirred evenly at 50° C. and then cooled to normal temperature to obtain a dimerized fatty acid-based vinyl ester resin.

Embodiment 2

[0040]Under a nitrogen atmosphere, put a certain amount of dimerized fatty acid in a reaction flask, stir and heat to 85°C, and add glycidyl methacrylate dropwise at a molar ratio of 2.5:1 to the dimerized fatty acid; 0.25% of the total mass of p-benzoquinone, adding 0.25% of the total mass of triethylbenzyl ammonium chloride, and then heating up to 140 ° C, refluxed for 1 h, to obtain the intermediate product dimer fatty acid unsaturated diglyceride; then the system Appropriately lower the temperature to 90°C, add crotene anhydride at a molar ratio of 2.5:1 to the dimerized fatty acid, reflux for 4 hours, and finally decolorize the dimerized fatty acid-based vinyl ester resin monomer with activated carbon; the obtained Resin monomer and propyl acrylate monomer were mixed in a mass ratio of 100:20, stirred evenly at 70°C and then cooled to room temperature to obtain dimerized fatty acid-based vinyl ester resin.

Embodiment 3

[0042] Under a nitrogen atmosphere, put a certain amount of dimerized fatty acid in a reaction flask, stir and heat to 85°C, and add glycidyl methacrylate dropwise at a molar ratio of 2.5:1 to the dimerized fatty acid; Add 0.25% of the total mass of 2-tert-butylhydroquinone to 0.25% of the total mass of tetramethylammonium chloride, then raise the temperature to 140 °C, and reflux for 1 h to obtain the intermediate product dimerized fatty acid-based unsaturated diglyceride Then the system is properly cooled to 70°C, and acrylic anhydride is added in a ratio of 2.5:1 to the dimer fatty acid molar ratio, refluxed for 4 hours, and finally the dimer fatty acid-based vinyl ester resin monomer is obtained by activated carbon decolorization; The prepared resin monomer and butyl acrylate were mixed in a mass ratio of 100:50, stirred evenly at 50° C. and then cooled to room temperature to obtain a dimerized fatty acid-based vinyl ester resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com