Preparation method of dispersing agent containing sulfo polycarboxylate

A sulfonic acid group-containing polycarboxylate and dispersant technology, which is applied in botany equipment and methods, biocides, animal repellants, etc., can solve the problem of long heat preservation time, unsatisfactory dispersion effect of copolymer dispersant, More expensive and other issues, to achieve the effect of short production cycle, product safety and stability, easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] One, the preparation of dispersant, the steps are as follows:

[0030] Preparation of solution A: Add 4.3236g of acrylic acid and 2.6028g of 1-hydroxypropyl acrylate into 17.5mL of water three times, and record it as solution A);

[0031] Preparation of solution A: Add 0.5130g of ammonium persulfate into 5.13mL of water, stir to dissolve, and record it as solution B.

[0032] Add 3.3158g AMPS to a four-neck flask equipped with a thermometer, stirrer, nitrogen tube, Y-shaped tube, and constant pressure dropping funnel, add 29mL three times of water, and then add 1.305mL isopropanol, heat up to 60°C, stir and pass Nitrogen for 30min. The temperature was raised to 65°C, and solution A and solution B were added drop by drop. Solution A was dropped in about 1 hour, and solution B was dropped in about 1.5 hours. The temperature was raised to 70° C., and the reaction was kept for 2.5 hours. After the solution is cooled below 30°C, add dropwise a 35% sodium hydroxide solutio...

Embodiment 2

[0050] Add 4.3236 g of acrylic acid and 2.6028 g of 1-hydroxypropyl acrylate into 11.5 mL of three times of water, add 1.025 g of ammonium persulfate into 10.25 mL of three times of water, stir and dissolve to obtain a mixed monomer solution.

[0051] Add 0.5130g of ammonium persulfate into 5.13mL of water, stir and dissolve to obtain an initiator solution.

[0052] Add 3.3158g AMPS to a four-necked flask equipped with a thermometer, stirrer, nitrogen tube, Y-shaped tube, and constant pressure dropping funnel, add 29.5mL of water for three times, then add 1.305mL of isopropanol, heat up to 58°C, pass Nitrogen for 30min. Raise the temperature to 68°C, add the mixed monomer solution and initiator solution drop by drop, the mixed monomer solution drops in about 1 hour, and the initiator solution drops in about 1.5 hours. The temperature was raised to 80° C., and the reaction was kept for 2.5 hours. After the solution is cooled below 30°C, add dropwise a 35% sodium hydroxide sol...

Embodiment 3

[0055] Add 4.3236 g of acrylic acid and 2.6028 g of 1-hydroxypropyl acrylate into 11.5 mL of water three times to obtain a mixed monomer solution; add 1.190 g of ammonium persulfate into 11.90 mL of water, stir and dissolve to obtain an initiator solution.

[0056] Add 4.974g AMPS to a four-necked flask equipped with a thermometer, stirrer, nitrogen tube, Y-shaped tube, and constant pressure dropping funnel, add 46.5mL of water for three times, then add 2.271mL of isopropanol, raise the temperature to 60°C, and blow nitrogen 30min. Raise the temperature to 67°C, add the mixed monomer solution and initiator solution drop by drop, the mixed monomer solution will be dropped in about 1 hour, and the initiator solution will be dropped in about 1.5 hours. The temperature was raised to 70° C., and the reaction was kept for 2.5 hours. After the solution is cooled below 30°C, add dropwise a 35% sodium hydroxide solution to adjust the pH to 7-8. The obtained solution was dropped into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

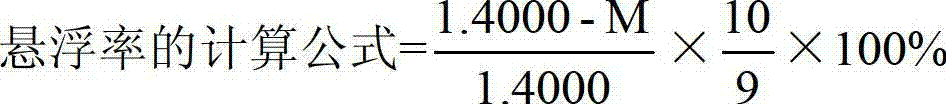

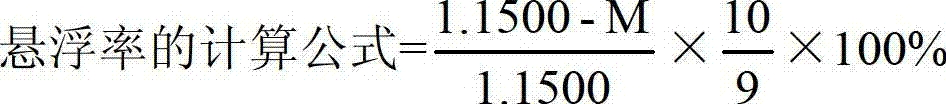

| suspension rate | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com