Chelation ion exchange fiber capable of resisting marine organism stain and preparation method thereof

A technology of marine biofouling and chelating ions, which is applied in ion exchange of chelates, ion exchange, fiber treatment, etc., can solve the problems of rare functional substances, rare chelated ion exchange fibers, and functional resins. It is difficult to withstand the problems of spinning, etc., and achieve the effect of fast adsorption and desorption, simple and easy preparation method, and high mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

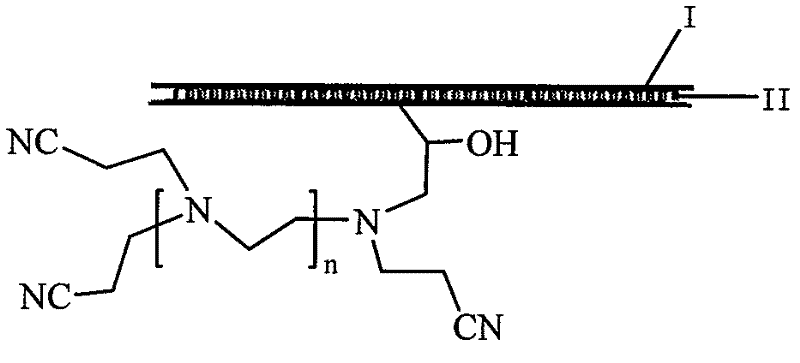

[0042] Example 1 Preparation method and application of anti-marine biofouling chelation ion exchange polyester-cotton blended yarn

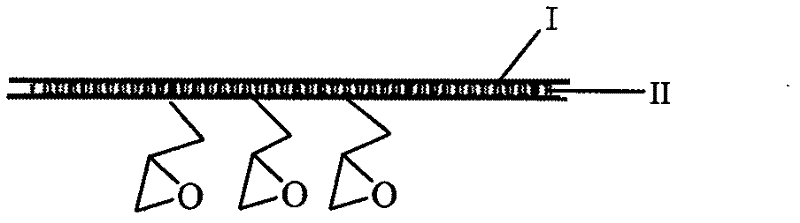

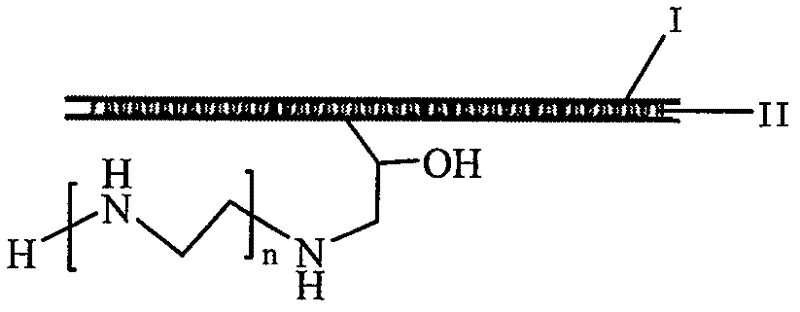

[0043] Step 1. Preparation of epoxy functional polyester-cotton blended yarn

[0044] Immerse 100 grams of commercially available 18 counts of 65 / 35 polyester-cotton natural color blended yarn into a polyester resin made of glycidyl methacrylate / methyl methacrylate / ethylene glycol dimethacrylate in a ratio of 75:10:15. Acrylate functional resin solution, padding three times at room temperature for 30 minutes, pulling out the yarn, drying, and gaining 95 grams in weight to obtain epoxy functional polyester-cotton blended yarn, which contains rings through chemical analysis. Oxygen 2.192mmol / g (the epoxy functional polyester-cotton blended yarn epoxy measured value is lower than the theoretical value, indicating that the preparation process of the polyacrylate functional resin solution and the hiding of the resin coating on the fiber surface will c...

Embodiment 2

[0052] Example 2 Preparation of anti-marine biofouling chelated ion-exchange polyester

[0053] According to the method and operation steps of Example 1, the commercially available 18-count 65 / 35 natural color polyester-cotton blended yarn in step 1 of Example 1 was replaced with commercially available 18S natural color polyester single yarn, and the anti-marine biofouling Chelated ion-exchange polyester, through adsorption experiments and chemical analysis, calculates that the retention adsorption capacity of anti-marine biofouling chelated ion-exchange polyester to copper chloride is 130.2mg / g.

Embodiment 3

[0054] Example 3 Preparation of anti-marine biofouling chelation ion exchange 32S / 2 acrylic fiber / cotton bulked yarn

[0055] According to the method and operation steps of Example 1, the commercially available 18 counts of 65 / 35 natural color polyester-cotton blended yarn in Step 1 of Example 1 was replaced with commercially available 32S / 2 acrylic fiber / cotton bulked yarn, and the anti-marine Biofouling chelated ion-exchanged acrylic / cotton bulked yarn, through adsorption experiments and chemical analysis, calculated the retention adsorption capacity of anti-marine biofouling chelated ion-exchanged acrylic / cotton bulked yarn to copper chloride was 483.3mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com