High-displacement-ability silicone fire-proof sealing glue and manufacturing method of the same

A fire-resistant sealant and sealant technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problem of high elongation, increased Shore A hardness, and elongation at break of silicone weather-resistant sealants. problems such as lowering, to achieve the effects of good adhesion, low smoke generation, and low energy consumption in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

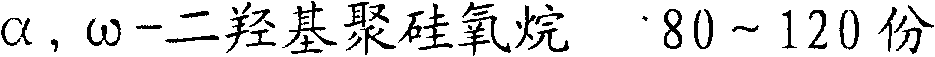

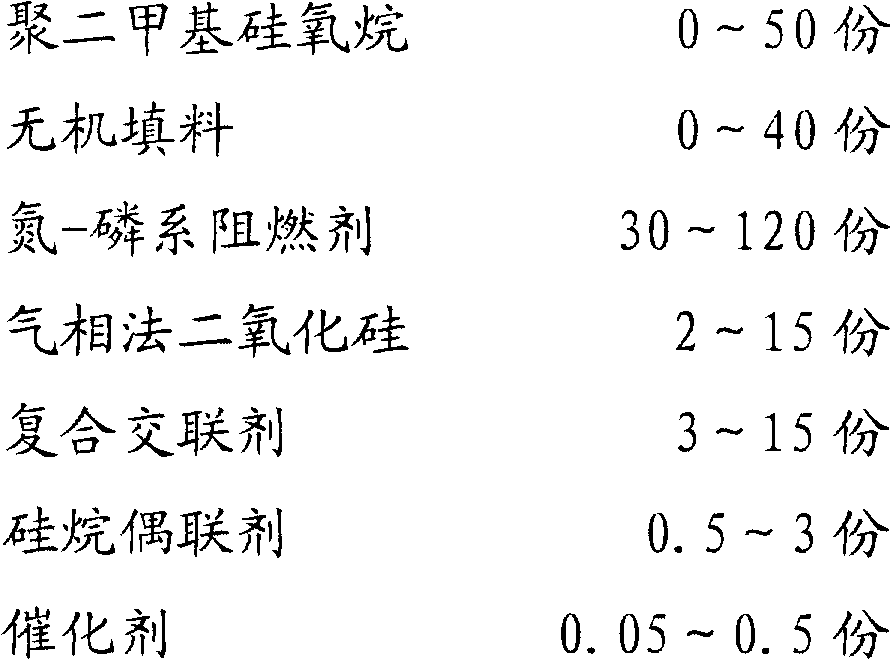

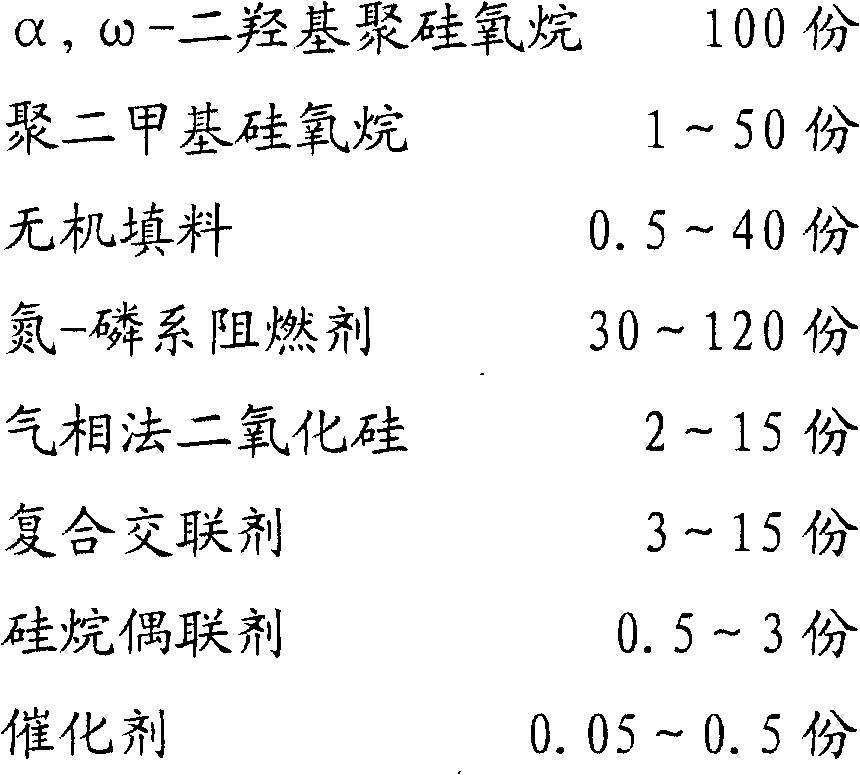

Method used

Image

Examples

Embodiment 1

[0031] 100 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 50 Pa.s at 25°C, 30 parts of polydimethylsiloxane with a viscosity of 0.1 Pa.s at 25°C, and nano-active calcium carbonate 30 parts, 30 parts of ammonium polyphosphate, and 50 parts of melamine borate were added to the kneader, at a temperature of 110 ° C, a vacuum of 0.09 MPa, dehydration and blending for 90 minutes, cooled to room temperature to obtain the base material; the above base material was added to the planetary Mixer, then add 2 parts of vinyl tributylketoxime silane, 8 parts of methyl tributylketoxime silane, 1 part of methylphenylbis(N-methylacetamido) silane, 6 parts of fumed silica , 2 parts of γ-aminopropyltriethoxysilane, 0.2 part of dibutyltin dilaurate, and the chemical reaction was carried out for 90 minutes at a vacuum degree of 0.09MPa and a rotation speed of 300rpm. The product performance indicators are shown in Table 1.

Embodiment 2

[0033] 100 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 80 Pa.s at 25°C, 40 parts of polydimethylsiloxane with a viscosity of 0.5 Pa.s at 25°C, and nano-active calcium carbonate 30 parts, 20 parts of melamine pyrophosphate, and 80 parts of melamine cyanurate were added to the kneader, dehydrated and blended for 60 minutes at a temperature of 120 ° C, a vacuum of 0.09 MPa, and cooled to room temperature to obtain a base material; the above base material was added to Planetary mixer, then add 3 parts of vinyl tributylketoxime silane, 4 parts of methyl tributylketoxime silane, 4 parts of methyl vinyl dibutylketoxime silane, 6 parts of fumed silica, N- 1.5 parts of β-aminoethyl γ-aminopropyl triethoxysilane, 0.2 parts of dibutyltin dilaurate, the chemical reaction was carried out for 90 minutes at a vacuum of 0.09 MPa and a rotation speed of 300 rpm. The product performance indicators are shown in Table 1.

Embodiment 3

[0035] 100 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 30 Pa.s at 25°C, 20 parts of polydimethylsiloxane with a viscosity of 5 Pa.s at 25°C, and 40 parts of nano-active calcium carbonate Parts, 30 parts of ammonium polyphosphate, 60 parts of melamine pyrophosphate, added to the kneader, at a temperature of 130 ° C, a vacuum of 0.09 MPa, dehydration and blending for 60 minutes, cooled to room temperature to obtain the base material; the above base material was added to the planetary Mixer, then add 6 parts of phenyl tributylketoxime silane, 3 parts of methyl tributyl ketoxime silane, 5 parts of fumed silica, 2 parts of γ-aminopropyl triethoxysilane, dilauric acid 0.2 parts of dibutyltin, the chemical reaction was carried out for 60 minutes at a vacuum degree of 0.09 MPa and a rotation speed of 300 rpm. The product performance indicators are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com