Preparation method of terephthalic type unsaturated polyester resin

A polyester resin and unsaturated technology, applied in the field of preparation of unsaturated polyester resin, can solve the problems of production and application limitations, difficult reaction, poor polyester compatibility, etc., and achieves low production cost, high reactivity, Excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

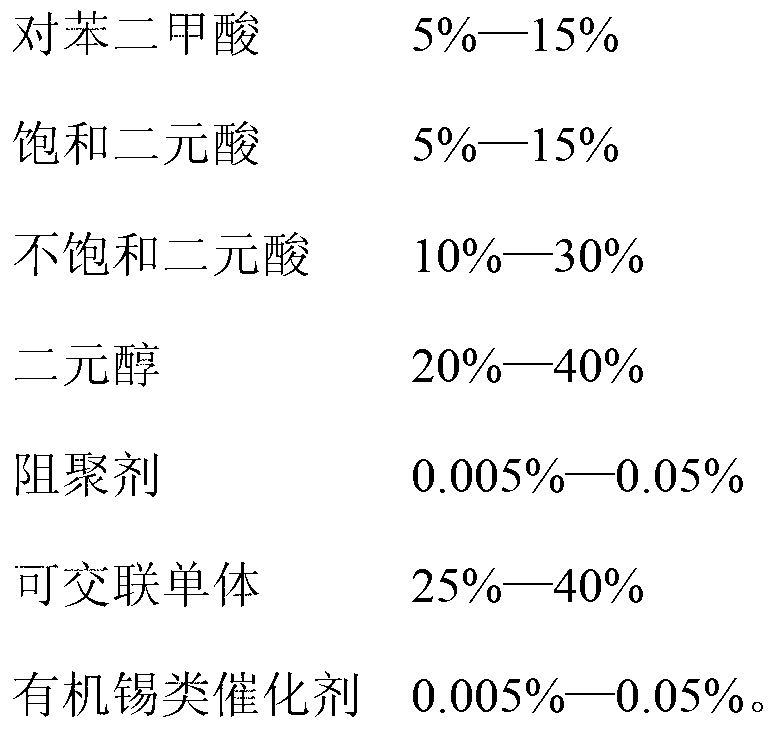

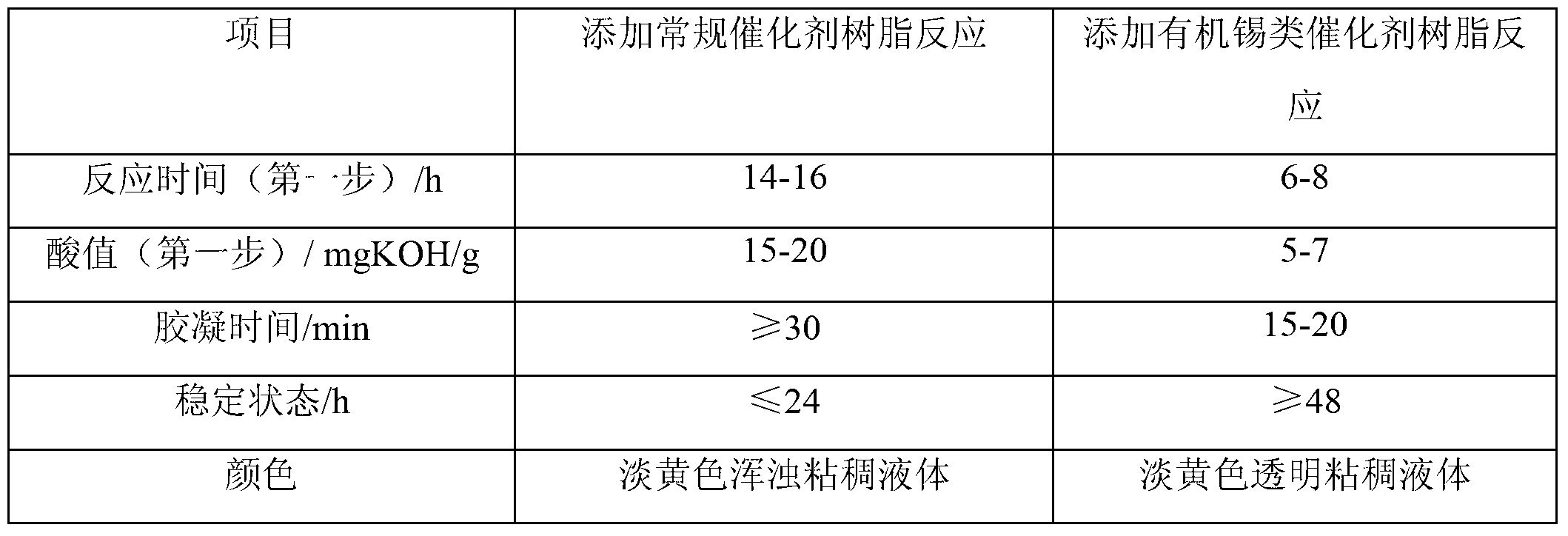

Method used

Image

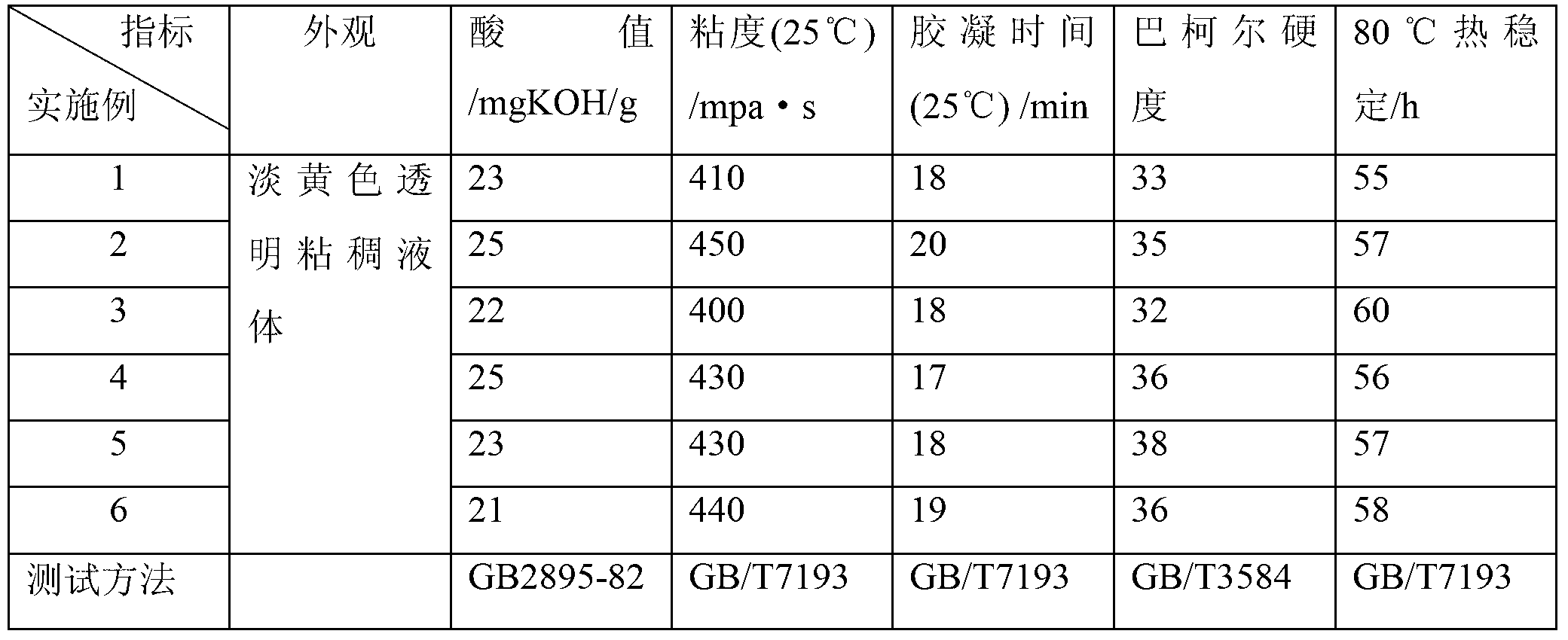

Examples

Embodiment 1

[0027] Add 200 g of terephthalic acid, 266 g of ethylene glycol, and 0.5 g of monobutyltin oxide into a reaction kettle equipped with a thermometer, a stirrer, a nitrogen inlet pipe and a condenser, and stir evenly. Rapidly raise the temperature to 160°C, pay attention to controlling the temperature of the distillation head, then gradually raise the temperature to 205°C, and react until the acid value is lower than 10mgKOH / g. Add 185g of propylene glycol, 83g of ethylene glycol, 184g of phthalic anhydride, 432g of maleic anhydride, and 0.045g of methylhydroquinone under stirring conditions, then gradually raise the temperature to 200°C, control the temperature of the distillation head, and react When the acid value is lower than 70mgKOH / g, polycondense under the vacuum degree of -0.07Mpa until the acid value is lower than 40mgKOH / g, cool down to 180°C and add 0.23g of methyl hydroquinone, cool down to 120°C and add 497.9g of styrene, After stirring evenly, the product p-phenyl...

Embodiment 2

[0029] Add 200 g of terephthalic acid, 177.7 g of propylene glycol, and 0.32 g of stannous octoate into a reaction kettle with a thermometer, a stirrer, a nitrogen inlet pipe and a condenser, and stir evenly. Rapidly raise the temperature to 170°C, pay attention to controlling the temperature of the distillation head, then gradually raise the temperature to 210°C, and react until the acid value is lower than 10mgKOH / g. Add 85g of butanediol, 183g of diethylene glycol, 150g of phthalic anhydride, 356g of fumaric acid, and 0.027g of hydroquinone under stirring conditions, then gradually raise the temperature to 200°C, and control the distillation head Temperature, react until the acid value is lower than 70mgKOH / g, polycondense at a vacuum degree of -0.08Mpa until the acid value is lower than 40mgKOH / g, cool down to 180°C and add 0.28g of hydroquinone, cool down to 120°C and add 456g of styrene, 155g of methyl methacrylate, after being stirred evenly, the product p-phenylene typ...

Embodiment 3

[0031] Add 200 g of terephthalic acid, 289 g of diethylene glycol, and 0.14 g of dimethyl tin into a reaction kettle equipped with a thermometer, a stirrer, a nitrogen inlet pipe and a condenser, and stir evenly. Rapidly raise the temperature to 180°C, pay attention to controlling the temperature of the distillation head, then gradually raise the temperature to 215°C, and react until the acid value is lower than 10mgKOH / g. Add 286g of dipropylene glycol, 225g of succinic acid, 322g of maleic acid, and 0.055g of p-tert-butylcatechol under stirring conditions, and then gradually raise the temperature to 200°C, control the temperature of the distillation head, and react until the acid value is low Polycondensate at 70mgKOH / g under vacuum degree -0.09Mpa until the acid value is lower than 40mgKOH / g, add 0.10g of p-tert-butylcatechol when cooled to 180°C, add 710g of divinylbenzene when cooled to 120°C, stir evenly The resulting product is phenylene type unsaturated polyester resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com