Offshore oilfield water injection well online one-step-process acidification technology

An offshore oilfield, single-step technology, applied in wellbore/well components, chemical instruments and methods, and production fluids, etc., can solve the problems of complex construction procedures, difficulty in optimal design of treatment fluid scale, time-consuming and labor-intensive, etc. To achieve the effect of simplifying the acid formula and construction process, realizing large-scale benefits, and saving the amount of acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

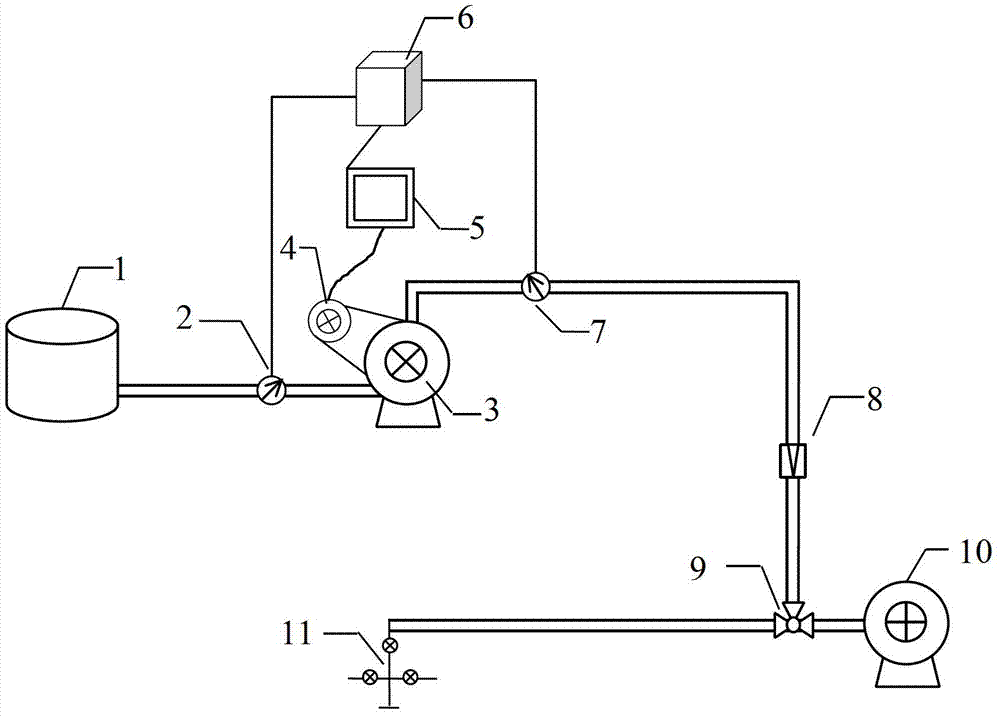

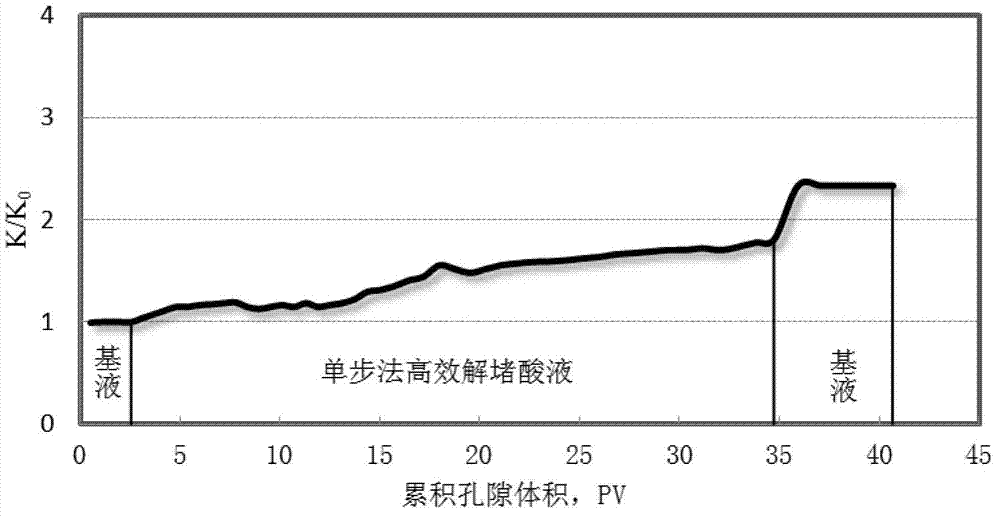

[0046] Embodiment 1: Taking the indoor simulation experiment of the core of Bozhong 25-1S oilfield of CNOOC as an example, the detailed description will be given.

[0047] Contaminated cores from the bottom of under-injection water injection wells in CNOOC Bozhong 25-1S Oilfield were used. The core is 3.542cm long, 2.52cm in diameter, with a porosity of 26% and a permeability of 1620×10 -3 μm 2 , to simulate the reservoir conditions, the acid fluid flow experiment was carried out at a temperature of 65°C and a confining pressure of 1 MPa. According to the injection sequence of "base fluid injection → single-step acid fluid injection → base fluid injection", the simulated acid fluid in The flow process of “water injection→injection of single-step plugging removal acid solution→water injection” in the formation.

[0048] The weight percentage of each component of the single-step acid solution used in the online single-step acidification: industrial acetic acid, 30%; industrial...

Embodiment 2

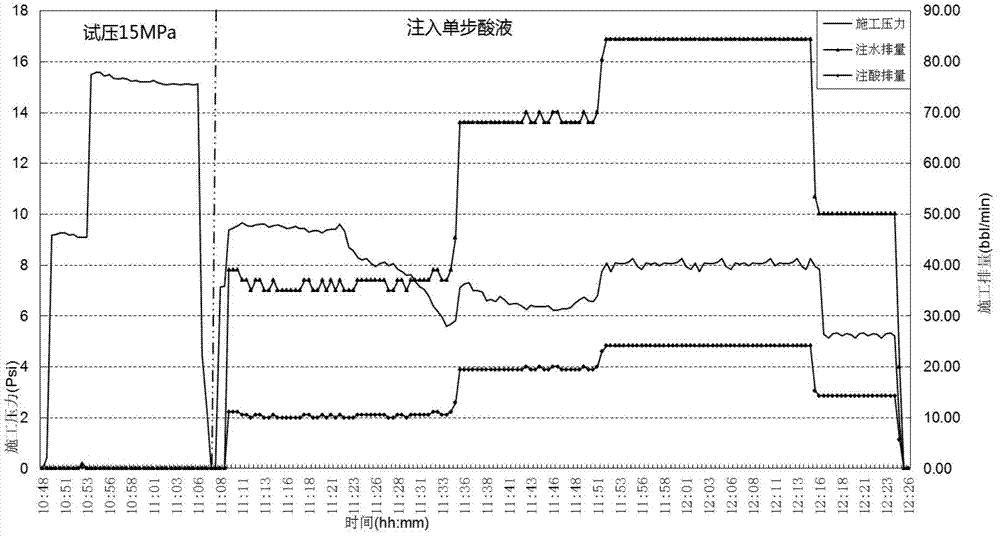

[0050] Example 2: Taking the online single-step acidification of layer C of water injection well QHD32-6-A7 in Qinhuangdao 32-6 oilfield of CNOOC as an example, it will be described in detail.

[0051] Well QHD32-6-A7 had a high injection pressure before acidizing layer C, the wellhead oil pressure was 8.9MPa, and the water injection rate was 10m 3 / h, and the injection pressure plus the net liquid column pressure tends to be greater than the formation fracture pressure. The research shows that the C layer of Well A7 is composed of suspended solids in the injected water, oil in the water and Fe(OH) 3 , CaCO 3 Scale caused blockage near the wellbore. In order to ensure the effective development of the oilfield, the on-line single-step acidizing technology is used for plug removal and injection enhancement.

[0052] QHD32-6-A7 water injection well C layer used in the online single-step acidification single-step acid liquid components weight percentage: industrial acetic acid,...

Embodiment 3

[0061] Example 3: Taking the QHD32-6-AW water injection well of CNOOC Qinhuangdao 32-6 Oilfield as an example, the online single-step acidification is described in detail.

[0062] The injection pressure of QHD32-6-AW water injection well before acidification is 9.5MPa, and the daily water injection volume is 22m 3 / h. Because the pump pressure is close to the rated working pressure, the injection is more difficult. The research shows that the AW well is injected with solid suspended solids, oil and Fe(OH) in the water. 3 , CaCO 3 Scale caused blockage near the wellbore.

[0063] QHD32-6-AW water injection well online single-step acidification acid liquid each component weight percent is the same as that of Example 2. A total of 30m prepared 3 Acid loading capacity is 30m 3 Skid mounted acid tank.

[0064] The online single-step acidizing process of QHD32-6-AW water injection well in CNOOC Qinhuangdao 32-6 oilfield is basically the same as that in Example 2, and the rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com