Extensible manufacturing/process control information portal server

a technology of information portal server and manufacturing process, which is applied in the direction of process and machine control, computer control, instruments, etc., can solve the problems of travel delays, considerable time and cost, and limited complexity and degree of control over a process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

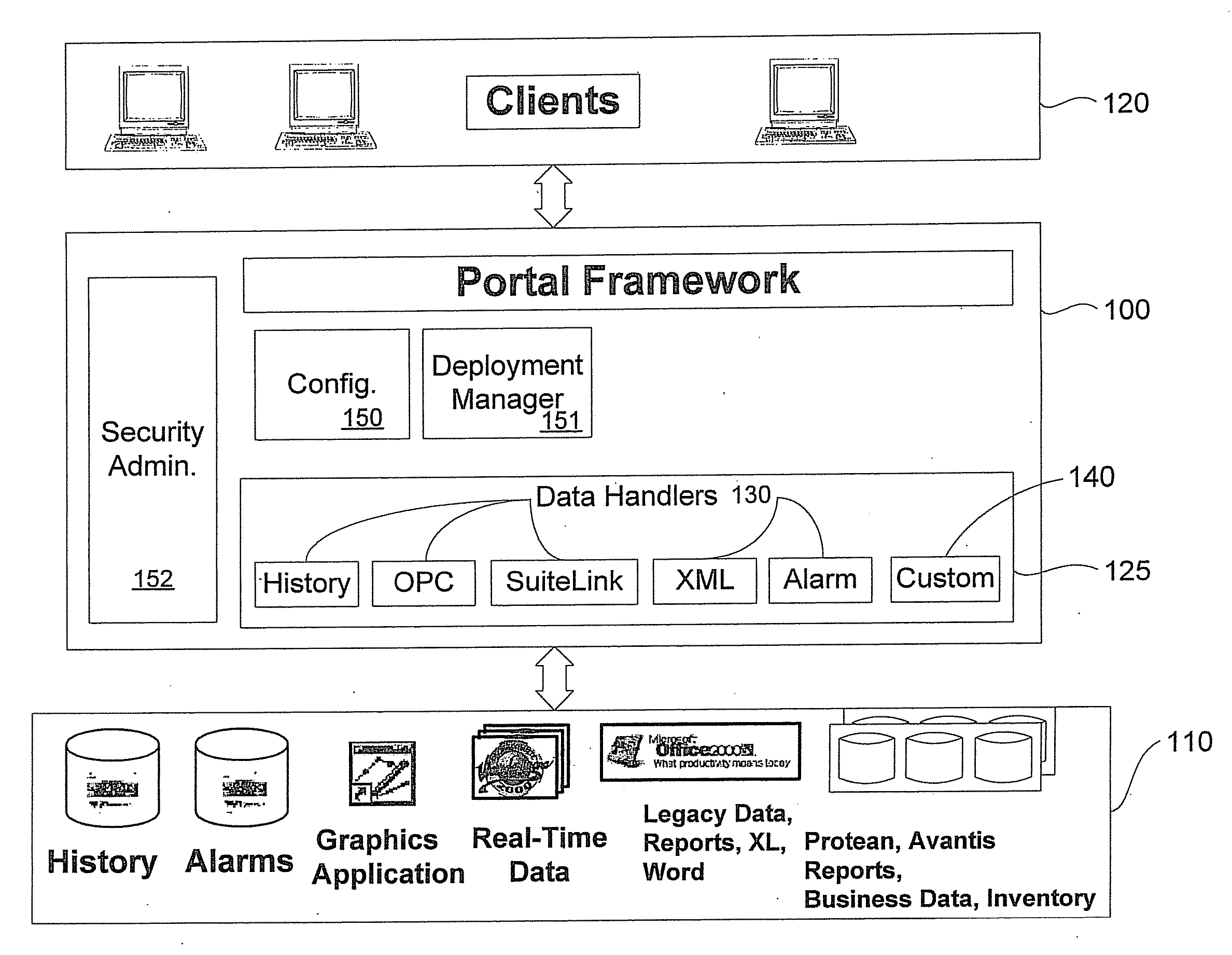

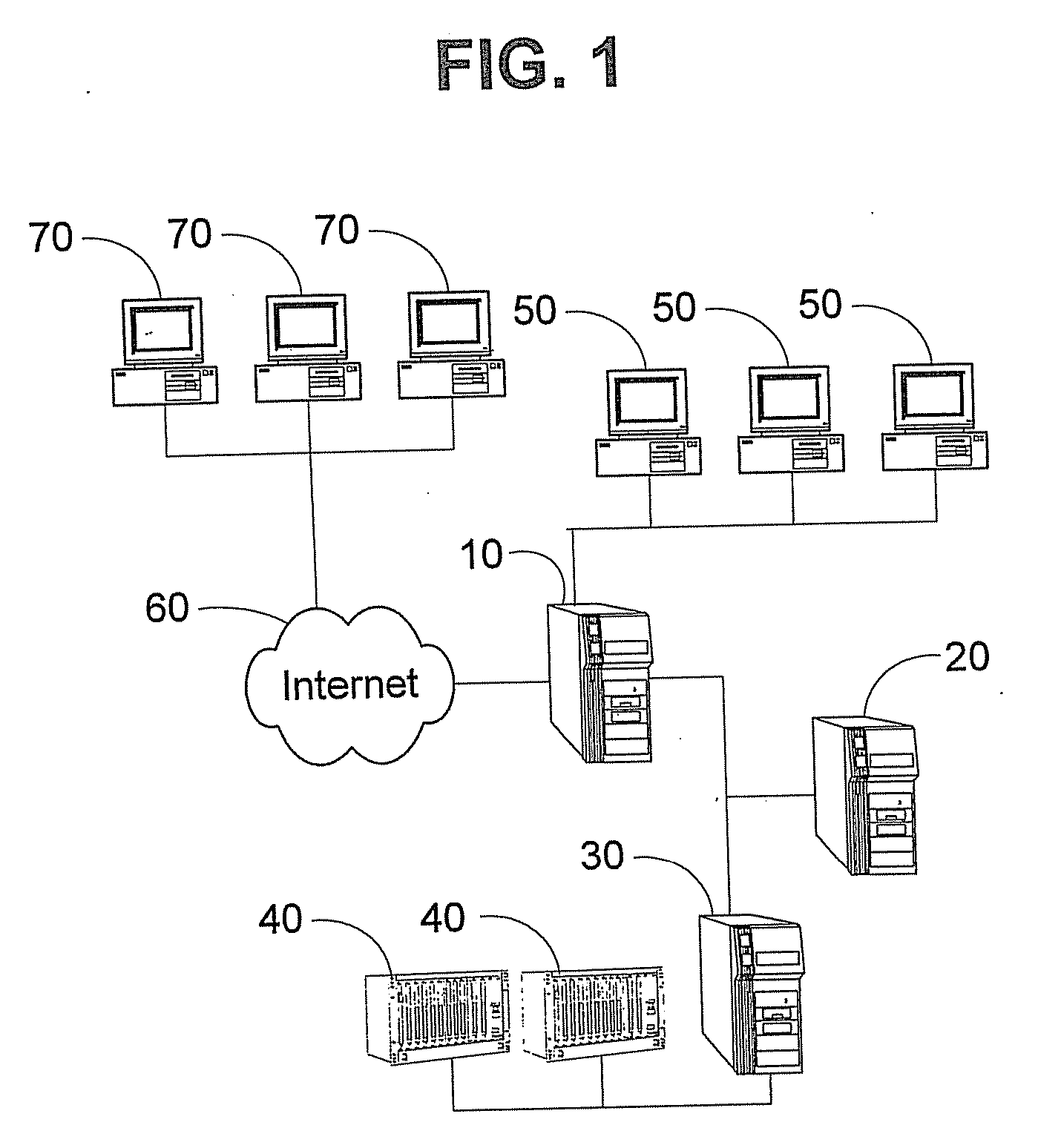

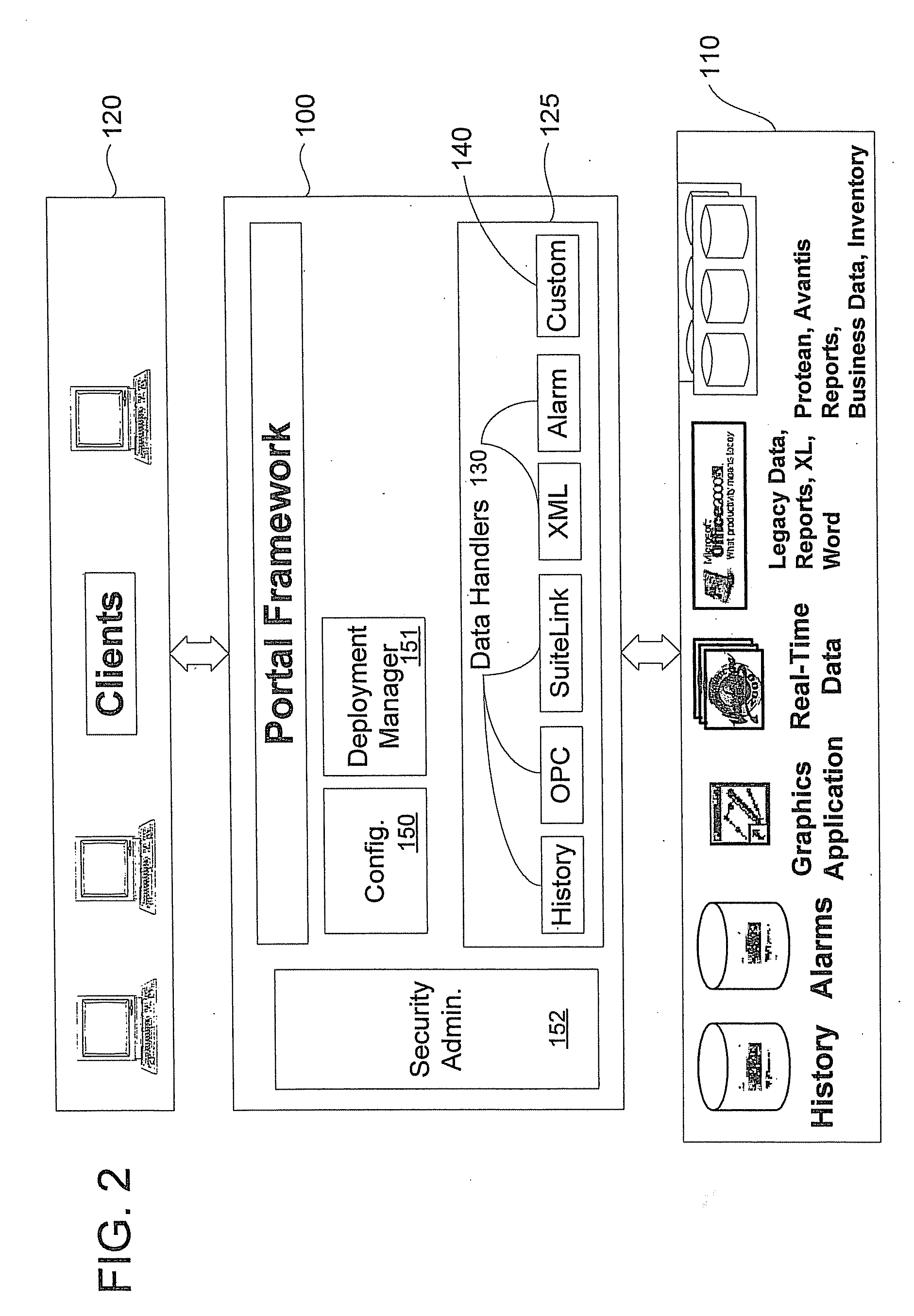

[0039] The present invention concerns an extensible manufacturing / process control information portal server that enables users to visualize plant floor information coming from a variety of systems and databases (e.g., Wonderware's InTouch systems, InTouch / AlarmSuite alarm databases, I / O servers, and Industrial SQL) over the Internet or an intranet via a browser (e.g., IE 5). The extensible manufacturing / process control portal server supports interactive HTML pages in XML, applying an XSL transformation, and dynamically rendering VML on a client machine (as well as providing animation updates from live process data sources). The portal server allows users to generate ad hoc queries of a real-time process control SQL database to produce trends and reports viewable with a browser client such as MICROSOFT'S INTERNET EXPLORER. In addition, the portal server supports Internet enabled ActiveX controls and a SQL server report tool. The manufacturing / process control portal server supports bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com