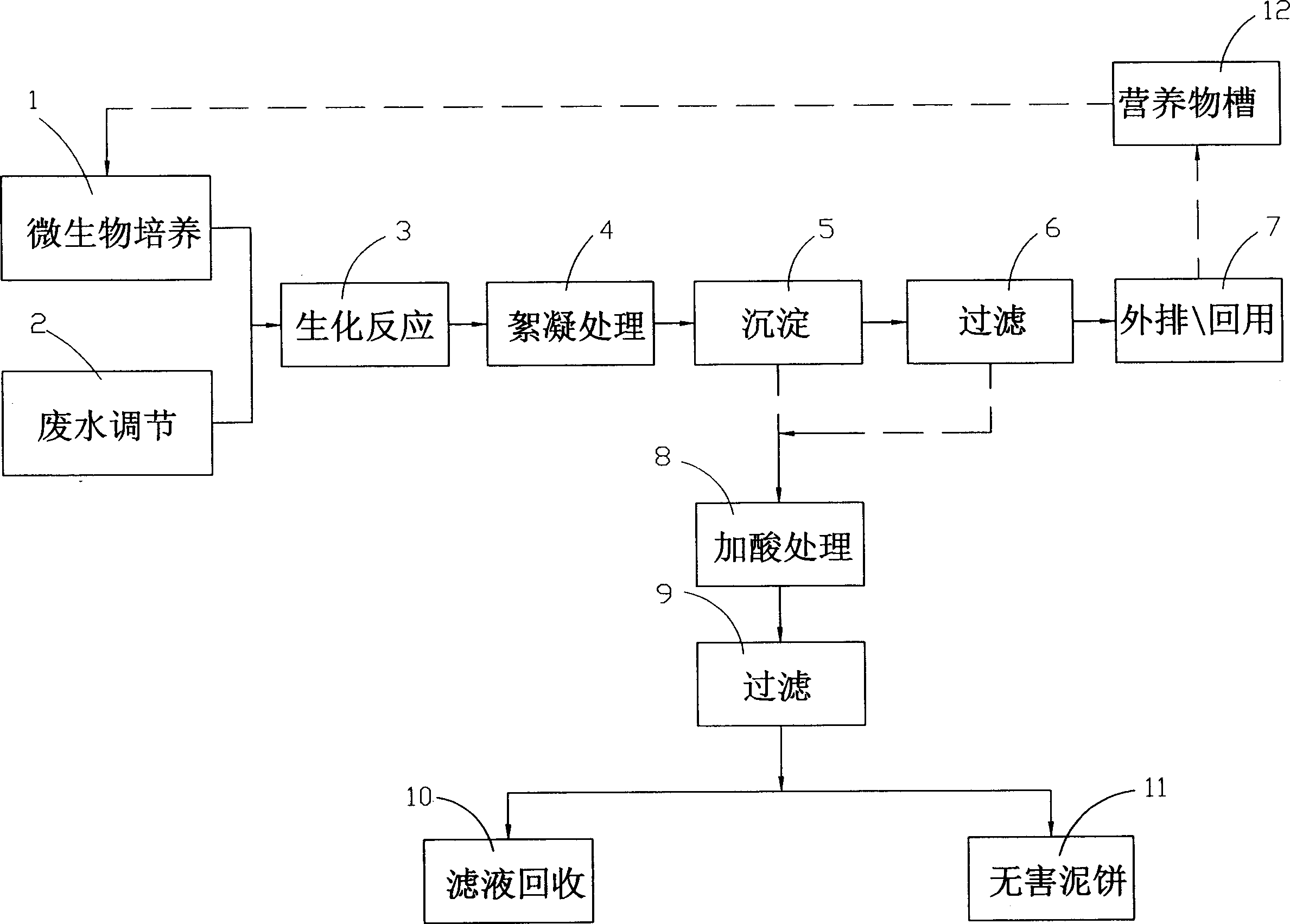

Technique and equipment for treating waste liquor containing high concentration chromium by microorganisms

A microbial treatment, high-concentration technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It does not involve the harmless treatment of the bacteria mud cake, the large volume of the structure, etc., to achieve the effect of reducing the floor space, good practical prospects, investment and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention processes cold-rolled color-coated steel coil passivation waste liquid containing high concentration of chromium. Cultivation conditions: temperature 38-40°C, pH 7.2-7.5, incubation time 36 hours. Since the pH of the original chromium-containing waste liquid is 3.6, the step of adjusting the pH value in the waste water adjustment tank is omitted. The waste water and the bacterial liquid pass through the pipeline mixer and enter the reaction tank for biochemical reaction according to the ratio of 1:1.5. The flocculation tank is 0.3‰ The cationic PAM flocculant with a concentration of 0.3‰ is added proportionally. After the mixed liquid is separated from the mud and water in the sedimentation tank, the supernatant is filtered through a PE filter and reused. The mud is treated with acid to produce harmless sludge and can be used as recycling The filtrate of chromium, zinc and nickel raw materials. The raw water quality and effluent water quality are randomly...

Embodiment 2

[0038] The present invention treats the high-concentration chromium passivation waste liquid of the cold-rolled hot-dip galvanizing production line. The bacteria cultivation method and the treatment steps are the same as above, except that the bacteria-to-waste ratio is adjusted to 1.7:1. The environmental protection statutory monitoring unit randomly samples and monitors: the influent water quality is: pH3.4, Cr 6+ 2064mg / L, total Cr 2790mg / L, Zn 2+ 366mg / L, Pb 2+ 0.46mg / L, Ni 2+ 0.15mg / L; the water quality of the treated water is: pH7.4, Cr 6+ 2+ 1.26mg / L, Pb 2+ 0.15mg / L, Ni 2+ 0.066mg / L. pH and Cr of effluent after treatment 6+ , total Cr, Zn, and Pb all reach the first-level emission standards stipulated by the state. Table 2 shows the comparison of monitoring results before and after treatment of cold-rolled galvanized sheet passivation high-concentration chromium waste solution.

[0039] pH

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com