Semi-coke waste water pretreatment method based on Electro-Fenton oxidization technology

A semi-carbon wastewater and pretreatment technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as high treatment cost, secondary pollution, and application limitations of Fenton's method , to achieve the effect of improving the degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

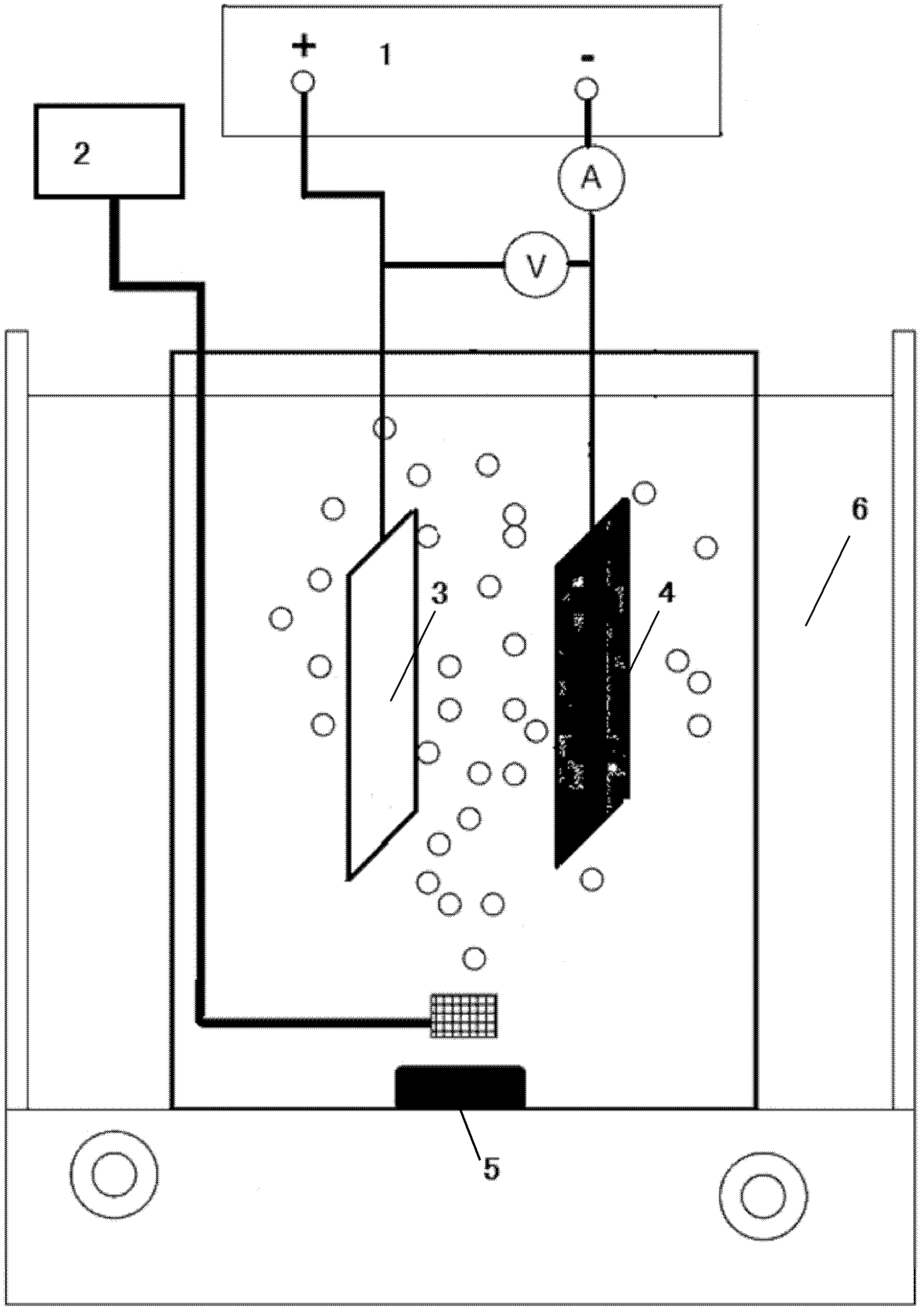

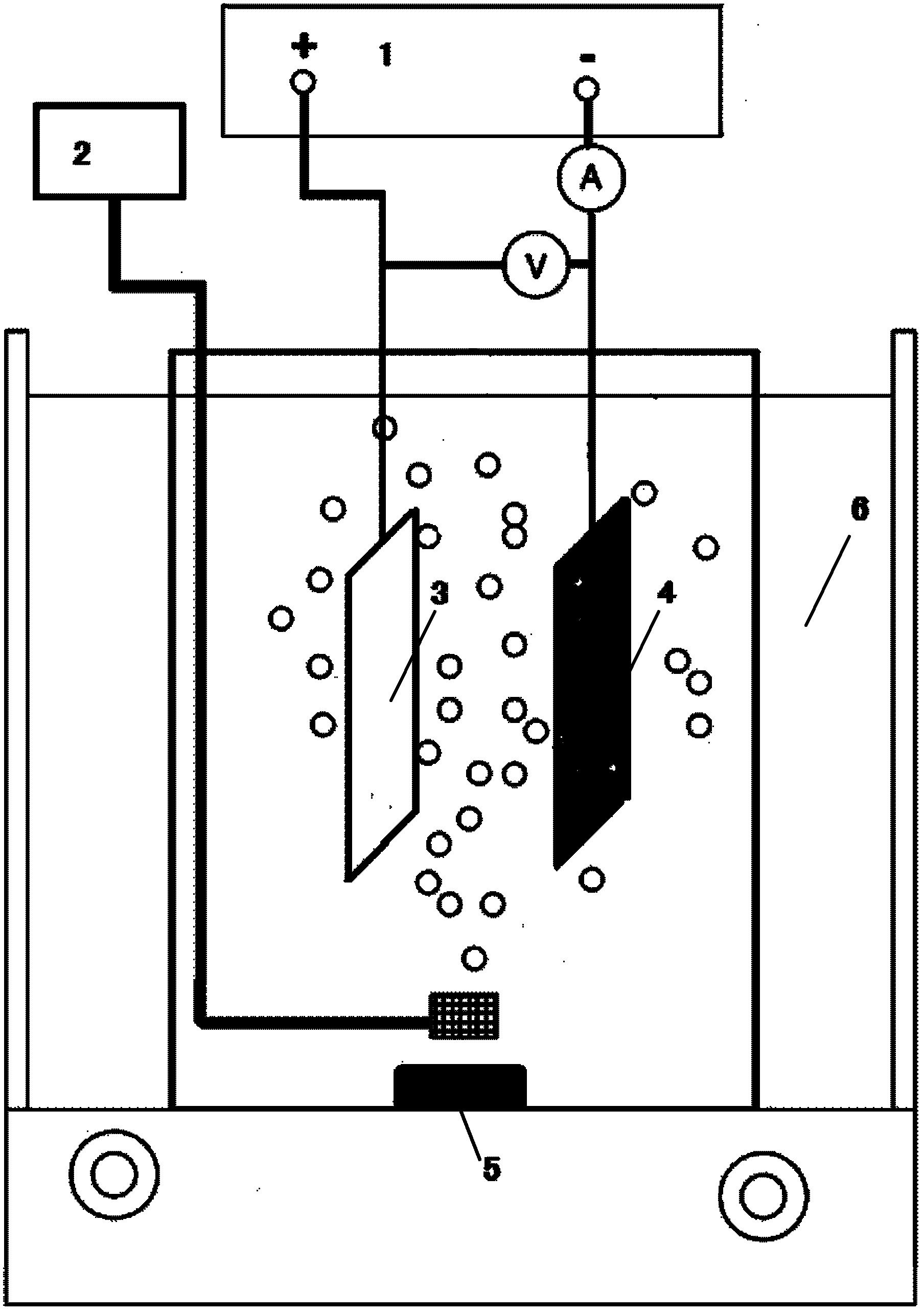

[0018] The working cathode used in this implementation example is a gas diffusion electrode with a stainless steel mesh as a conductive and supporting framework, and a mixture of graphite, polytetrafluoroethylene, pore-forming agent and catalyst as a catalytic coating; the anode is an ordinary stainless steel plate electrolytically treated blue carbon waste water. In order to increase the processing capacity of the device, the gas diffusion electrode and the stainless steel anode are connected in parallel by multiple sets of electrodes. Keep the air flow in the wastewater at 2.5L / min and the current density at 5.2mA / cm 2 , the distance between the plates is 2cm, and the pH value of the wastewater is adjusted to 3 for electrolysis. After treatment, the COD removal rate of wastewater can reach 78.62%.

Embodiment 2

[0020] The working negative electrode that this implementation example adopts is the gas diffusion electrode that is the gas diffusion electrode of catalytic coating with the mixture of graphite, polytetrafluoroethylene, pore forming agent and catalyzer, and the length, width, The heights are 6cm, 4cm, and 0.2cm respectively; the anode is an ordinary stainless steel plate for electrolytic treatment of blue carbon wastewater. In order to increase the processing capacity of the device, the gas diffusion electrodes and stainless steel anodes are connected in series by multiple sets of electrodes. As shown in the figure, the current density is controlled by a DC power supply to 8.0mA / cm 2 , keep the distance between the plates at 1.5cm, adjust the pH value of the wastewater to 4, and the ventilation rate of the wastewater to 2.5L / min for electrolysis. After treatment, the ammonia nitrogen removal rate of the wastewater can reach 68.50%.

Embodiment 3

[0022] The working cathode used in this implementation example is a gas diffusion electrode with a stainless steel mesh as a conductive and supporting framework, a mixture of graphite, polytetrafluoroethylene, a pore-forming agent and a catalyst as a catalytic coating, and graphite, polytetrafluoroethylene to form a diffusion catalytic layer The mass ratio of vinyl fluoride, pore-forming agent and catalyst is 8:2:1:0.01; the anode is an ordinary stainless steel plate to electrolytically treat semi-coke wastewater. In order to increase the processing capacity of the device, the gas diffusion electrodes and stainless steel anodes are connected in series by multiple sets of electrodes. As shown in the figure, the current density is controlled by a DC power supply to 6.0mA / cm 2 , keep the distance between the plates at 1.5cm, adjust the pH value of the wastewater to 3, and the ventilation rate of the wastewater to 2.5L / min for electrolysis. After treatment, the COD removal rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com