High-temperature resisting oil field scale inhibitor with emulsifying function and preparation method thereof

A technology of emulsification and scale inhibitor, applied in the field of high temperature resistant oilfield scale inhibitor and its preparation, which can solve the problems of paralysis of oilfield gathering and transportation system, interruption or stop of oilfield exploitation and transportation, pipeline rupture and blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

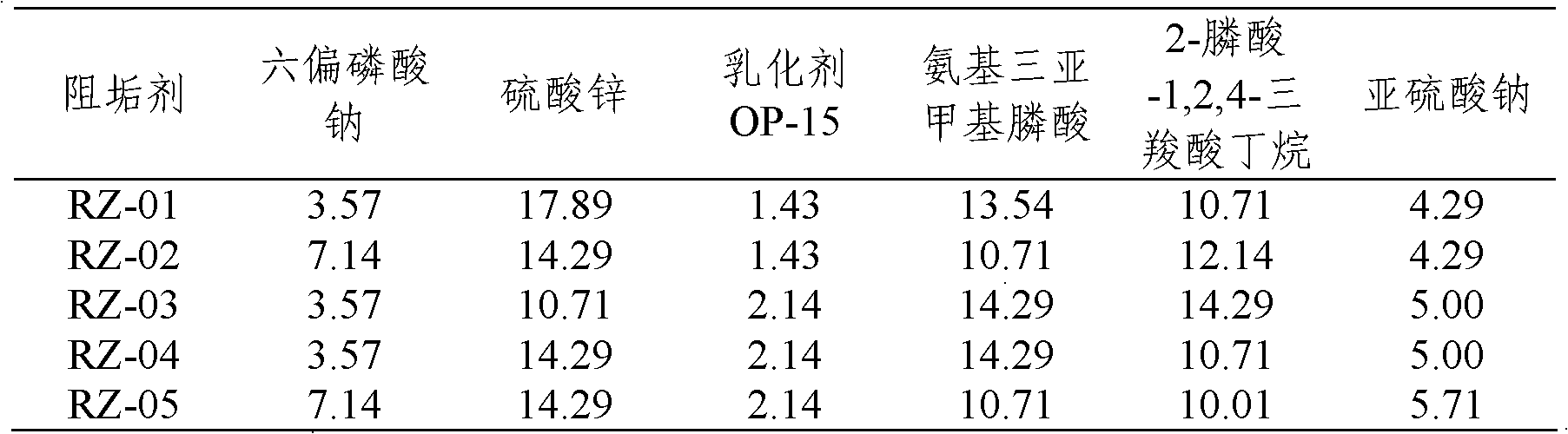

[0014] Preparation of antiscalant: prepare emulsifying high temperature resistant oil field antiscalant according to the weight ratio of the components in Table 1, add water to the reaction kettle, then add sodium hexametaphosphate, stir for 20 minutes, and then add a single agent Stir the medium liquid single agent for 5 minutes, finally add zinc sulfate and the remaining single agent and stir for 10 minutes to obtain the finished scale inhibitor.

[0015] Table 1 prepares scale inhibitor weight ratio of each agent

[0016]

[0017] The obtained scale inhibitors RZ-01, RZ-02, RZ-03, RZ-04 and RZ-05 are all colorless and transparent liquids.

Embodiment 2

[0018] Embodiment 2 Examples of corrosion and scale inhibition performance evaluation of scale inhibitors:

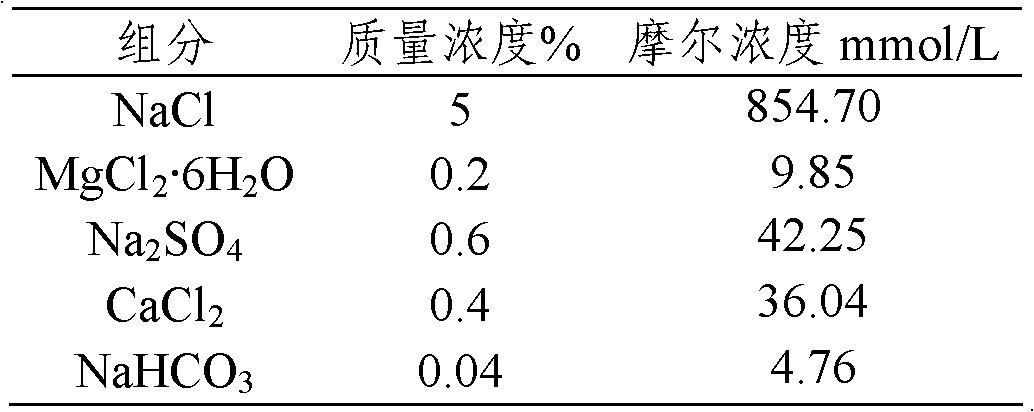

[0019] Scale inhibitor performance evaluation is based on SY-T5273-2000 performance evaluation method of corrosion inhibitor for oilfield produced water and SY-T5673-1993 performance evaluation method of oilfield antiscalant agent. The test water was prepared with reference to the water quality characteristics of the oil field to prepare the test corrosive solution (see Table 2 for the specific composition of the corrosive solution). The water used to prepare the corrosive solution was distilled water, and the medicine was analytical reagent.

[0020] Table 2 Components of self-made corrosion solution

[0021]

[0022] Take the above-mentioned RZ-01 antiscalant agent, use oil and gas industry standard corrosion test piece (executive standard (SY-5273), material (Q235-A (A3)), specification: 76mm×13mm×2.5mm, surface area 24.21cm 2 )experimenting. According to the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com