Cu-based organic skeleton-graphene oxide composite porous material and preparation method thereof

A graphene composite and organic framework technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of large-scale industrial production of difficult metal organic framework materials, high production costs of MOFs materials, and secondary pollution of the environment , to achieve the effect of short reaction time, large preparation amount and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

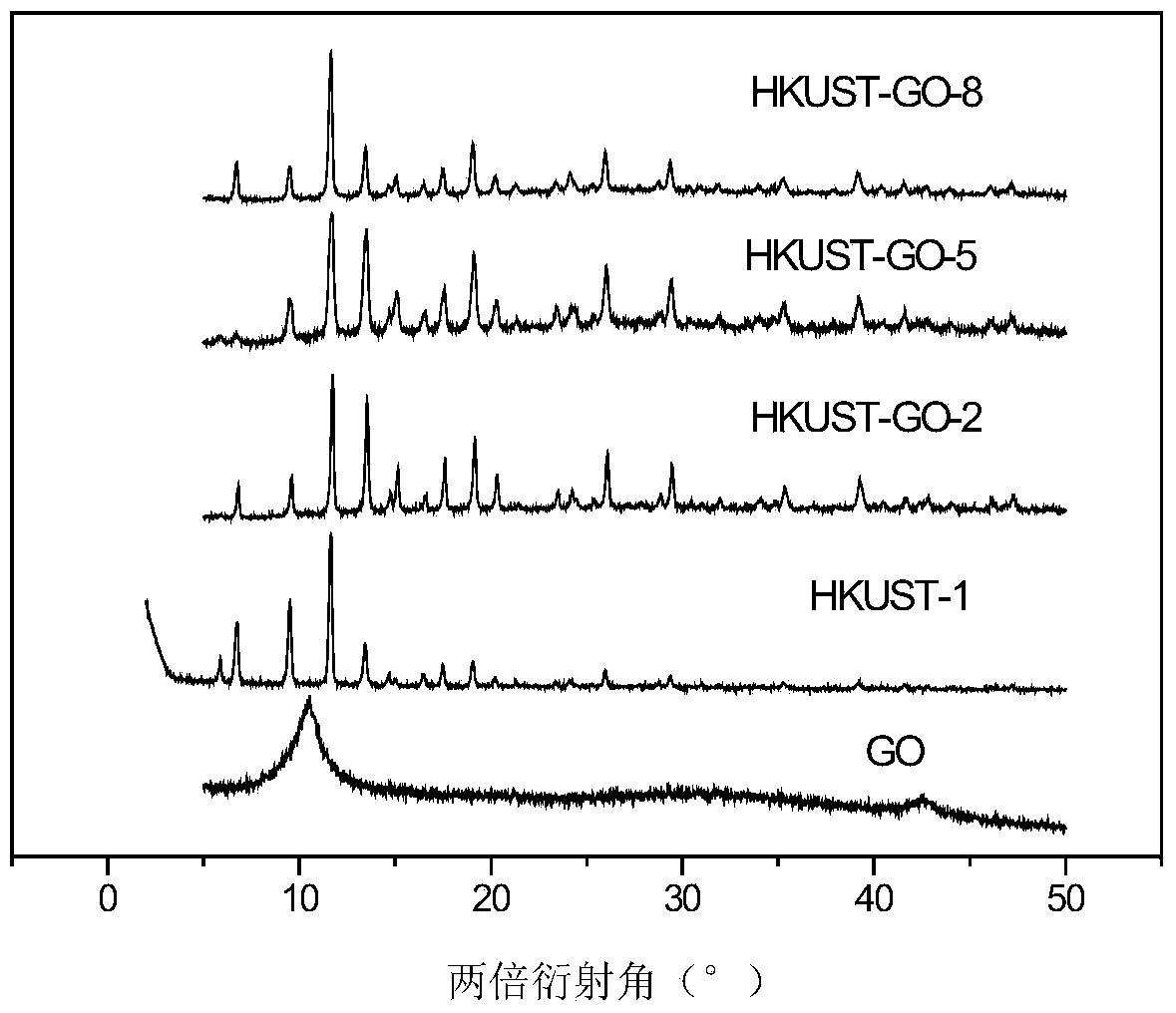

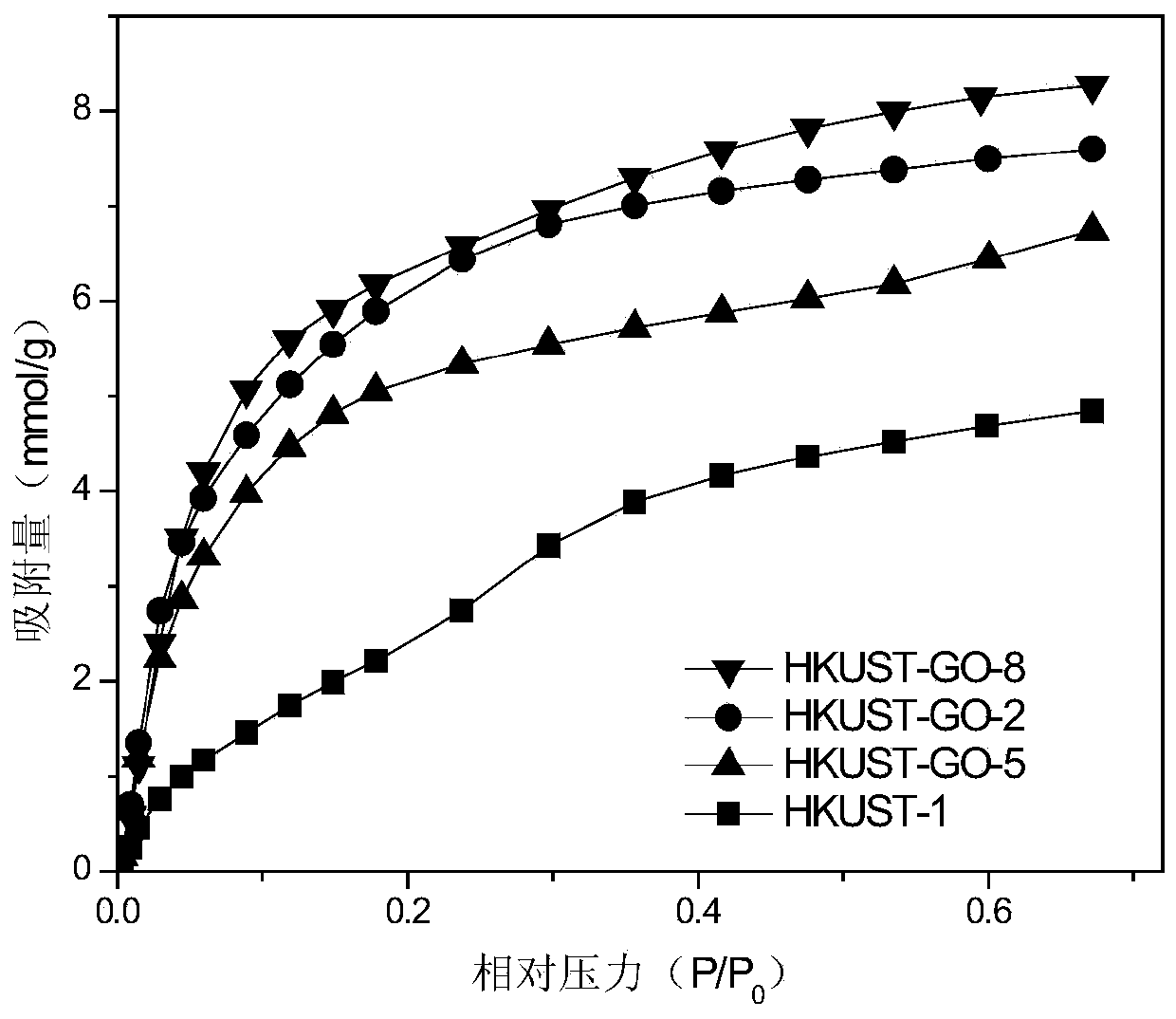

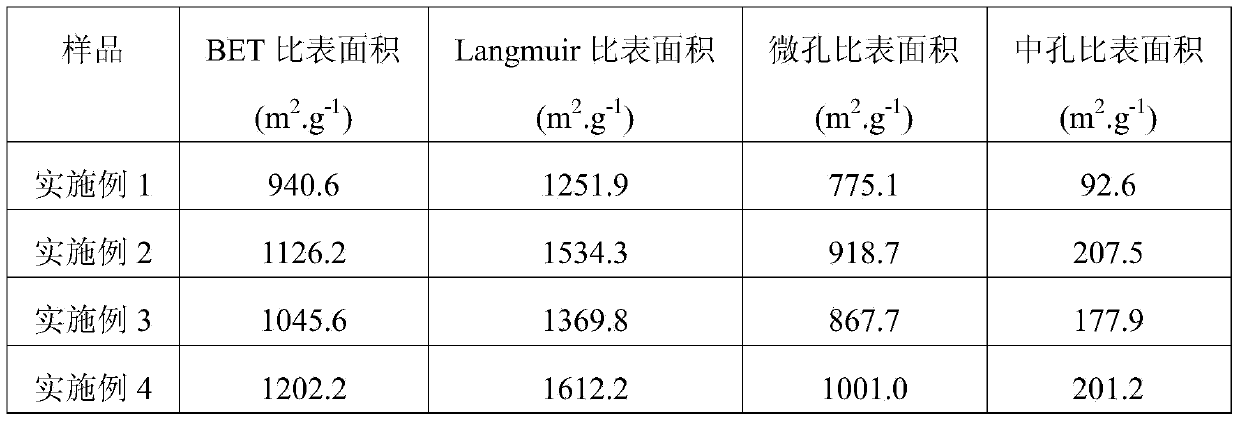

[0034] Embodiment 1: comparative example

[0035] 1.204g Cu(CH 3 COO) 2 ·H 2O and 0.808g of 1,3,5-benzenetricarboxylic acid were put into a stainless steel ball mill jar, added stainless steel ball mill beads, put into the ball mill, and then ball milled at 1100r / min (42.97Hz) for 30-45min, and the obtained solid powder was successively After washing with ethanol water solution (ethanol: water ratio of 1:1) and chloroform, centrifuge and filter at 5000-7000r / min to obtain the product, put it in an oven for drying at 100-180°C, and mark this sample as HKUST-1.

Embodiment 2

[0036] Example 2: Preparation of Cu-based organic framework-graphene oxide composite porous material

[0037] 1.204g Cu(CH 3 COO) 2 ·H 2 O and 1.144g1,3,5-benzenetricarboxylic acid are put into stainless steel ball mill jar, then add 0.0470g graphene oxide (as Cu(CH 3 COO) 2 ·H 2 O and 2% of the total mass of 1,3,5-benzenetricarboxylic acid), and mix evenly, add stainless steel ball milling beads, put them into the ball mill, and then ball mill for 45min under the condition of 1150r / min (46.75Hz), and the obtained solid powder After washing with ethanol water solution (ethanol: water ratio of 1:1) and chloroform in sequence, the product is extracted by centrifugal filtration at 5000~7000r / min, and the product is dried in an oven at 100~180°C, and the sample is marked as HKUST-GO-2 .

Embodiment 3

[0038] Example 3: Preparation of Cu-based organic framework-graphene oxide composite porous material

[0039] 1.701g Cu(CH 3 COO) 2 ·H 2 O and 0.808g1,3,5-benzenetricarboxylic acid are put into stainless steel ball mill jar, then add 0.125g graphene oxide (as Cu(CH 3 COO) 2 ·H 2 O and 5% of the total mass of 1,3,5-benzenetricarboxylic acid), and mix evenly, add stainless steel ball milling beads, put them into the ball mill, and then ball mill for 60min under the condition of 1100r / min (42.97Hz), and the obtained solid powder After washing with ethanol aqueous solution (ethanol: water ratio of 2:1) and chloroform in sequence, extract the product by centrifugal filtration at 5000-7000r / min, put the product in an oven for drying at 100-180°C, and mark this sample as HKUST-GO-5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com