Composite low-phosphorus corrosion and scale inhibitor and application thereof

A corrosion and scale inhibitor, compound application technology, applied in the direction of scale removal and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of long-term operation without production equipment, damage to ecological balance, environmental Pollution and other problems, to achieve the effect of low phosphorus content, pollution reduction, wide pH range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A compound low-phosphorus corrosion and scale inhibitor formula, which is composed of corrosion and scale inhibitor A and corrosion and scale inhibitor B, wherein:

[0024] Corrosion and scale inhibitor A is made by mixing polyepoxysuccinic acid (PESA), sodium gluconate, and water, and the weight ratio of each component is:

[0025] Polyepoxysuccinic acid (PESA) 20 parts

[0026] Sodium Gluconate 40 parts

[0027] 40 parts of water

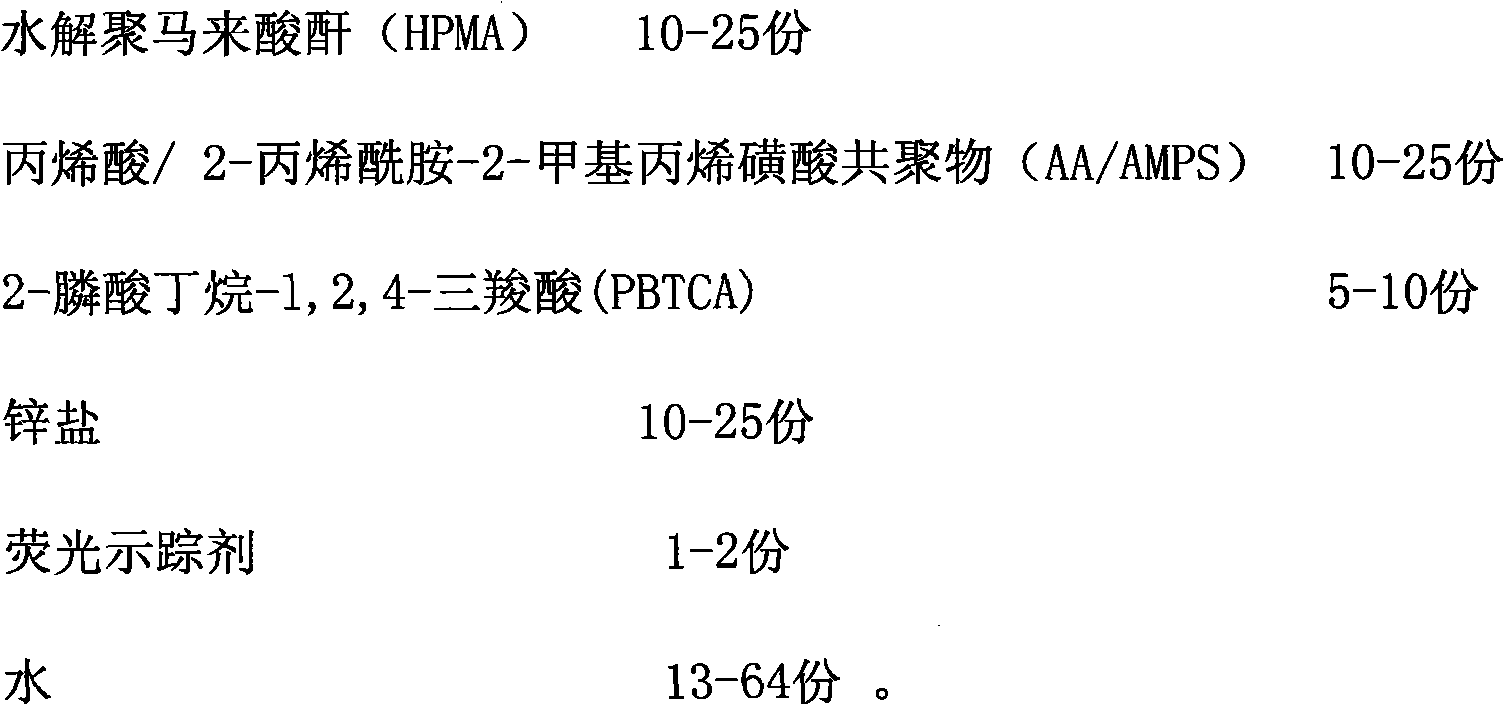

[0028] Corrosion and scale inhibitor B consists of hydrolyzed polymaleic anhydride (HPMA), acrylic acid / 2-acrylamide-2-methylpropenesulfonic acid copolymer (AA / AMPS), 2-phosphonic acid butane-1,2,4 -Tricarboxylic acid (PBTCA), zinc salt, fluorescent tracer, and water are mixed, and the weight ratio of each component is:

[0029]

[0030] The zinc salt is zinc sulfate.

[0031] The above composite low-phosphorus corrosion and scale inhibitor formula is applied to circulating cooling water, and 30 mg of corrosion and scale inhibitor A ...

Embodiment 2

[0033] A compound low-phosphorus corrosion and scale inhibitor formula, which is composed of corrosion and scale inhibitor A and corrosion and scale inhibitor B, wherein:

[0034] Corrosion and scale inhibitor A is made by mixing polyepoxysuccinic acid (PESA), sodium gluconate, and water, and the weight ratio of each component is:

[0035] Polyepoxysuccinic acid (PESA) 25 parts

[0036] Sodium Gluconate 20 parts

[0037] 55 parts of water

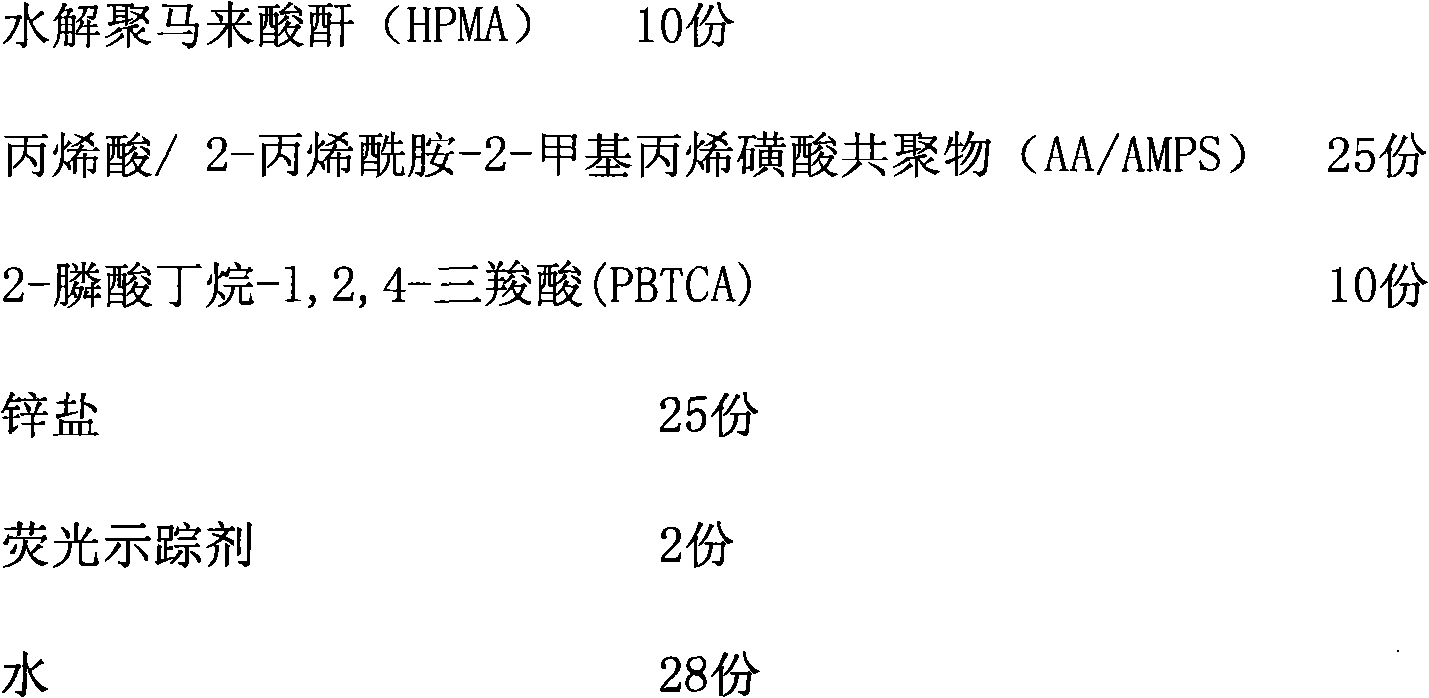

[0038] Corrosion and scale inhibitor B is made by mixing hydrolyzed polymaleic anhydride (HPMA), acrylic acid / 2-acrylamide-2-methylpropenesulfonic acid copolymer (AA / AMPS), zinc salt, fluorescent tracer, and water , the weight ratio of each component is:

[0039]

[0040]

[0041] The zinc salt is zinc sulfate.

[0042] The above composite low-phosphorus corrosion and scale inhibitor formula is applied to circulating cooling water, and 35 mg of corrosion and scale inhibitor A and 70 mg of corrosion and scale inhibitor B are added ...

Embodiment 3

[0044] A compound low-phosphorus corrosion and scale inhibitor formula, which is composed of corrosion and scale inhibitor A and corrosion and scale inhibitor B, wherein:

[0045] Corrosion and scale inhibitor A is made by mixing polyepoxysuccinic acid (PESA), sodium gluconate, and water, and the weight ratio of each component is:

[0046] Polyepoxysuccinic acid (PESA) 30 parts

[0047] Sodium Gluconate 20 parts

[0048] 50 parts of water

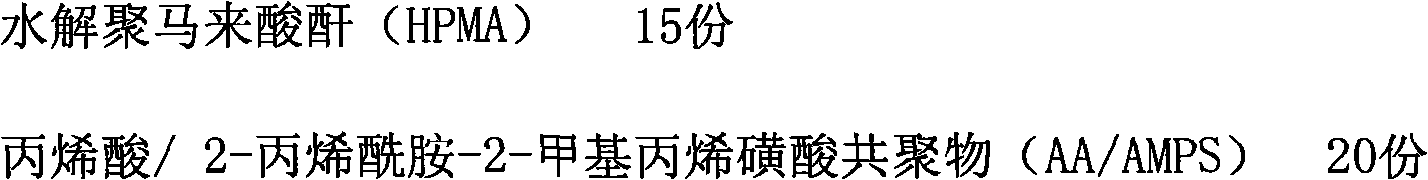

[0049] Corrosion and scale inhibitor B is made by mixing hydrolyzed polymaleic anhydride (HPMA), acrylic acid / 2-acrylamide-2-methylpropenesulfonic acid copolymer (AA / AMPS), zinc salt, fluorescent tracer, and water , the weight ratio of each component is:

[0050]

[0051] The zinc salt is zinc sulfate.

[0052] The above composite low-phosphorus corrosion and scale inhibitor formula is applied to circulating cooling water, and 40 mg of corrosion and scale inhibitor A and 80 mg of corrosion and scale inhibitor B are added to each 1 li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com