Sewage filter cleaning agent and preparation thereof

A sewage filter and cleaning agent technology, which is applied in the field of oil field chemistry, can solve the problems of low filtration efficiency, sewage water quality that cannot meet the requirements of water injection standards, and unsatisfactory backwashing effect, etc., and achieve the effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

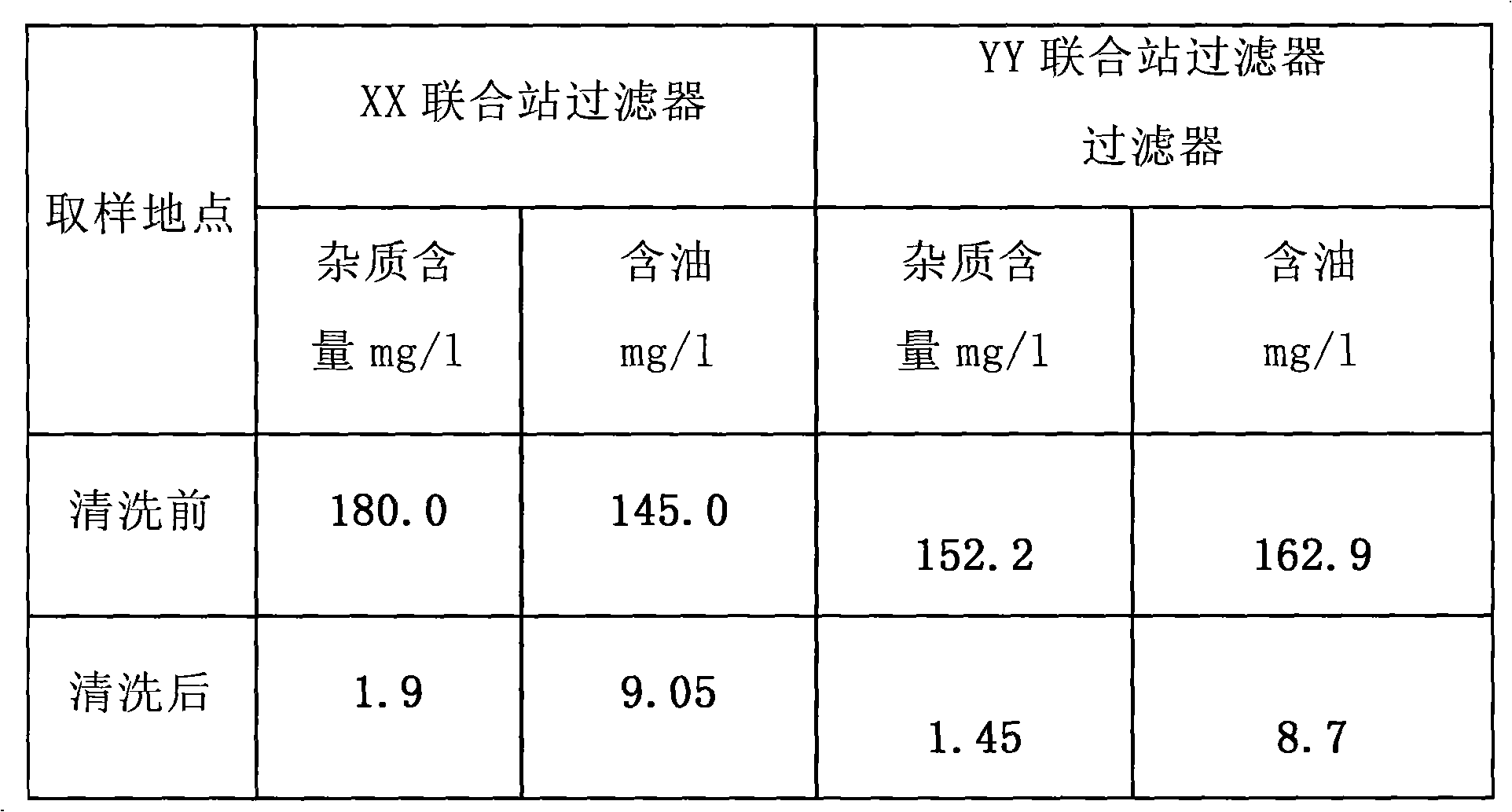

Image

Examples

Embodiment 1

[0035] The weight ratio of each component of sewage filter cleaning agent is:

[0036] 1. Citric acid (industrial product): 7%

[0037] 2. Hydrochloric acid (industrial product) (industrial product); 4.5%

[0038] 3. Alias of hydroxy-1,1-ethylenediphosphonic acid sulfonic acid (industrial product), GY-9200: 0.15%

[0039] 4. Alkylphenol polyoxyethylene (14) ether (industrial product): 5.5%

[0040] 5. The rest is water, and the sum of the weight percentages of each component is 100%.

[0041] Preparation Process:

[0042] First, five raw materials including citric acid, hydrochloric acid, hydroxy-1,1-ethylenediphosphonic acid sulfonic acid, hydroxy-1,1-ethylenediphosphonic acid sulfonic acid, and water are added in proportion to the normal pressure enamel reaction kettle . Stir continuously for 30 minutes.

[0043] Finally, add alkylphenol polyoxyethylene (14) ether in proportion, stir while adding, and discharge after stirring for 20 minutes to obtain a sewage filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com