A process and design method for removing coke and deposits in hydrogenation process

A technology for coking and deposits, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, corrosion/fouling inhibition of treatment equipment, etc., can solve problems such as coking and deposition in hydrogenation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This example is an example of dredging the sediment and a small amount of coke at the bottom of the reactor in the oil-coal slurry bed hydrogenation process.

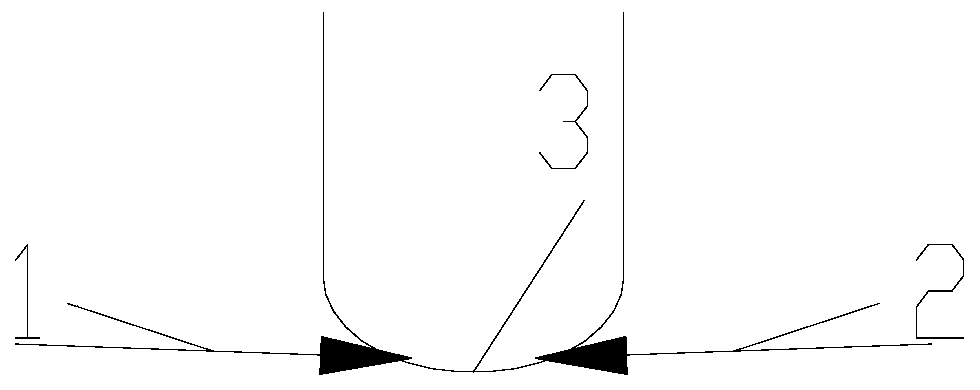

[0029] like figure 1 As shown, at the bottom of the reactor 3, there is a viscosity detector and a pressure difference detector (not shown), the measured viscosity is 980cSt, and the pressure difference is 120KPa, then start dredging, the dredging direction is along the tangential direction of the inner wall, and the dredging pipeline is a reaction Dredge pipes 1 and 2 at the bottom of the device, the remover is 400-500°C distillate oil and 0.1wt% naphthenate and 0.1wt% amino trimethylene phosphonic acid, the initial dredging speed is 15m / s, and the dredging temperature is 450 ℃, when the viscosity of the medium drops to 500cSt, the dredging speed drops to 9m / s. The 400-500°C distillate in the removal agent mentioned above has a moderate molecular weight, and will not be cracked into gas in a short period of tim...

Embodiment 2

[0031] This example is to dredge the top of the reactor in the oil-coal slurry bed hydrogenation process, and remove the coking accumulation caused by the poor flow of the medium at the outlet of the reactor top.

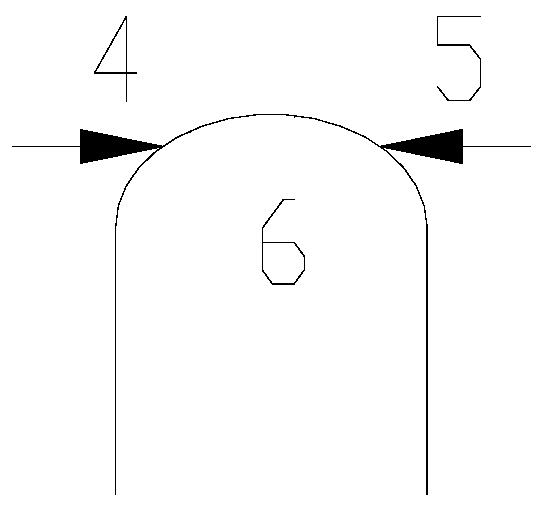

[0032] like figure 2 As shown, there is a viscosity detector and a pressure difference detector (not shown) at the top of the reactor 6, the viscosity measured by the viscosity detector is 780cSt, the pressure difference is 105KPa, the dredging direction is horizontal, and the dredging pipeline is the top of the reactor. Unclog pipes 4 and 5, remover is 370-430°C distillate oil and 0.7wt% benzenesulfonate, 0.3wt% diethylenetriaminepentamethylenephosphonic acid, 0.1wt% pH=7.5-9 For C9 fatty acid salt, the initial dredging speed is 13m / s, the dredging temperature is 450°C, and after the medium viscosity drops to 350cSt, the dredging speed drops to 9m / s. Distillate oil at 370-430°C has a moderate density and will not affect the quality of light products at the outlet...

Embodiment 3

[0034]In this embodiment, dredging is set across the line of the regulating valve at the outlet of the low-pressure separator. Under normal circumstances, the medium flow rate is small or no, and it is easy to form a blockage at the regulating valve, which affects the need for large flow medium to pass through.

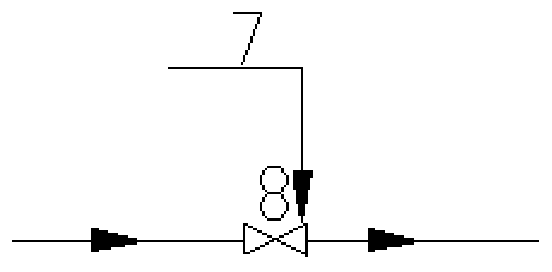

[0035] like image 3 As shown, a viscosity and a differential pressure detector (not shown) are arranged on the pipeline 8 where the valve is located. The viscosity measured by the viscosity detector is 800cSt, the differential pressure is 100KPa, and the remover is 300-350°C distillate oil and 0.5wt% naphthenate and 0.5wt% ethylenediaminetetraacetic acid and hydroxyethylene diphosphonic acid, the dredging direction is the opposite direction of normal flow, which is the valve dredging pipe 7, and the initial dredging speed is 13m / s, The dredging temperature is 280°C, and when the pressure difference drops to 45KPa, the dredging speed drops below 8m / s. The properties ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com