Additive for improving early strength of white cement and preparation method and application of additive

An early strength and admixture technology, which is applied in the field of preparation of admixtures to improve the early strength of white cement, can solve the problems of white cement strength shrinkage, strength shrinkage, and large dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

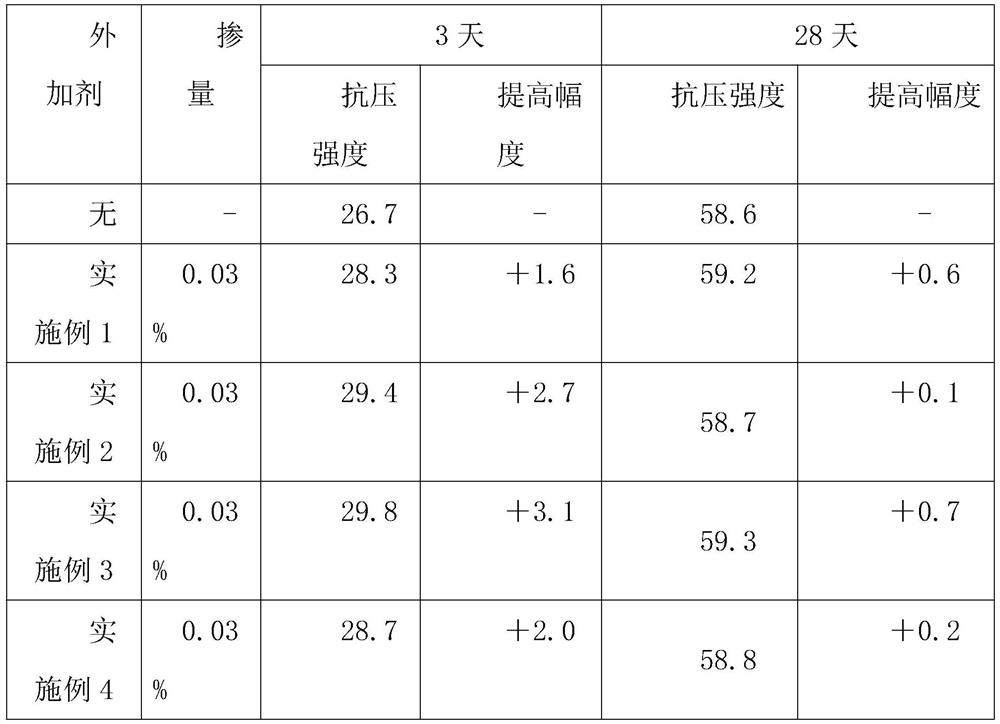

Examples

Embodiment 1

[0019] Get 15 parts of phosphonoglycolic acid, 15 parts of hydroxyethylidene diphosphonic acid, 10 parts of tetrasodium aminotrimethylene phosphonate, 10 parts of sodium thiocyanate and 50 parts of water.

[0020] Add water to the reaction kettle, then add tetrasodium aminotrimethylene phosphonate and sodium thiocyanate, fully dissolve and stir evenly, then add phosphonoglycolic acid and hydroxyethylenediphosphonic acid dropwise, and continue stirring after the dropwise addition 15 minutes to get the finished product.

Embodiment 2

[0022] Get 15 parts of phosphonoglycolic acid, 15 parts of hydroxyethylene diphosphonic acid, 10 parts of ethylenediamine tetramethylene phosphonic acid, 5 parts of tetrasodium aminotrimethylene phosphonate, 6 parts of sodium thiocyanate and 49 parts of water.

[0023] Add water to the reaction kettle, then add tetrasodium aminotrimethylene phosphonate and sodium thiocyanate, fully dissolve and stir evenly, then add dropwise phosphonoglycolic acid, hydroxyethylene diphosphonic acid, ethylenediamine tetramethylene Phosphonic acid, after the dropwise addition, continued to stir for 15 minutes to obtain the finished product.

Embodiment 3

[0025] Get 15 parts of ethylenediamine tetramethylene phosphonic acid, 8 parts of disodium hydroxyethylidene diphosphonate, 10 parts of tetrasodium aminotrimethylene phosphonate, 10 parts of sodium thiocyanate and 57 parts of water.

[0026] Add water to the reaction kettle, then add tetrasodium aminotrimethylene phosphonate, tetrasodium aminotrimethylene phosphonate, sodium thiocyanate, fully dissolve and stir evenly, then add ethylenediamine tetramethylene phosphonic acid dropwise, drop Continue stirring for 15 minutes after the addition to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com