Novel rosin imidazoline corrosion inhibitor

A technology of rosin-based imidazoline and corrosion inhibitor, which is used in wellbore/well components, earthwork drilling, organic chemistry, etc., achieves the effects of high corrosion inhibition rate, reduced corrosion loss and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

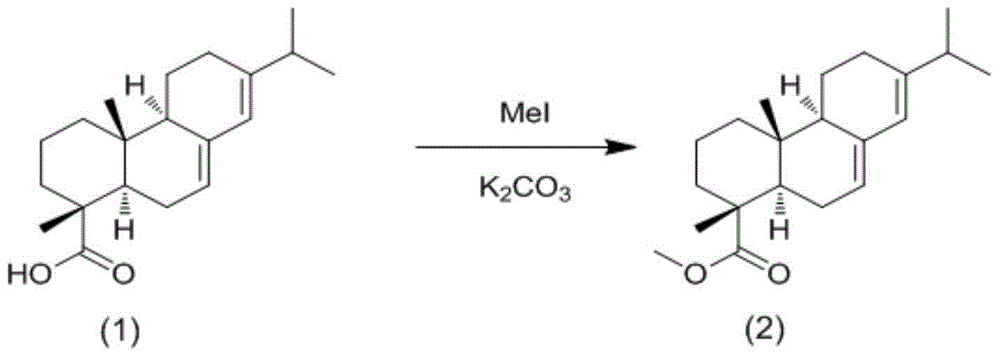

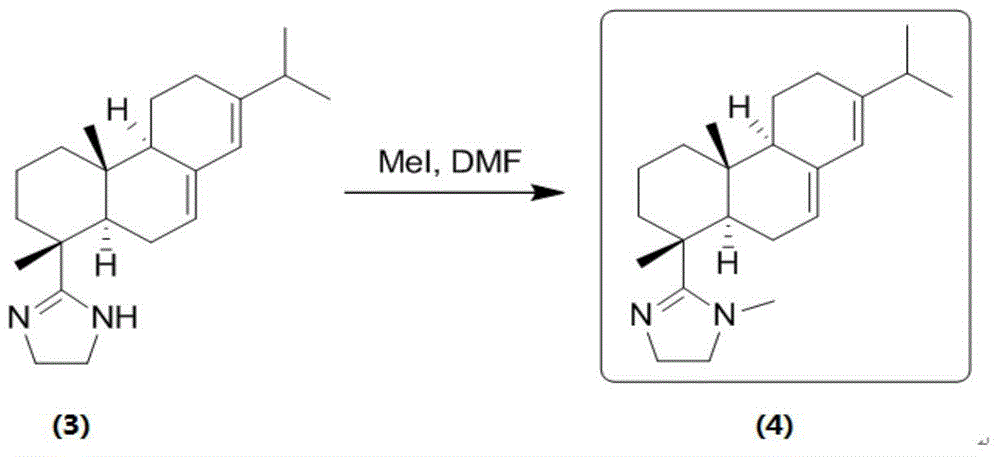

[0025] A kind of synthetic method of formula (4) compound, its step is as follows:

[0026] Step a: the synthesis of formula (2) compound:

[0027] 100g abietic acid (0.331mol) and 69gK 2 CO 3 (0.497mol) was dissolved in 800ml of dimethylformamide solvent, and 56.4 grams (0.397mol) of MeI was added, stirred for 3 hours and plated to confirm that the reaction was complete. Remove MeI by rotary evaporation under reduced pressure, extract and concentrate with EA, wash with water to remove DMF solvent, wash the organic layer with saturated sodium chloride, dry and concentrate, and the remaining components are purified by 1:10 EA / PE through a silica gel column to obtain 100 g of formula (2) Compounds.

[0028] 1 HNMR (CDCl 3 ,400MHz):0.75(m,7H);0.94(m,6H);1.18(m,7H);1.50(m,4H),1.73(m,6H);2.01(m,4H);2.14(m, 1H); 3.55(s,3H); 5.29(d,1H); 5.70(s,1H).

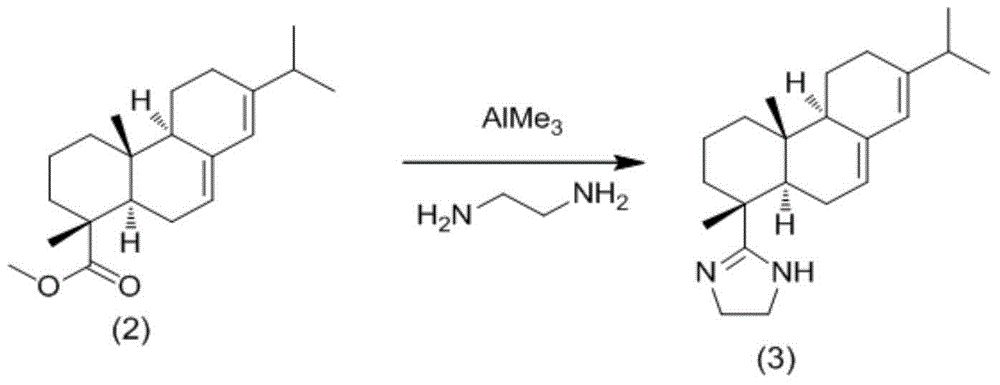

[0029] Step b: Synthesis of the compound of formula (3):

[0030] At 0-10°C, add 57.0g (0.949mol) ethylenediamine and 0.949molA...

Embodiment 2

[0036] First, the compound of formula (4) prepared in Example 1 is prepared into a corrosion inhibitor, and the corrosion inhibitor is composed of a compound of formula (4), dimethylformamide, hydroxyethylene diphosphonic acid and water, specifically The content range is as follows:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com