A kind of oil well water-based wax remover and preparation method thereof

A water-based technology for removing wax and preventing wax, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. The problem is to improve the effect of wax removal, enhance the effect of wax removal and prevent loss, and reduce the loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

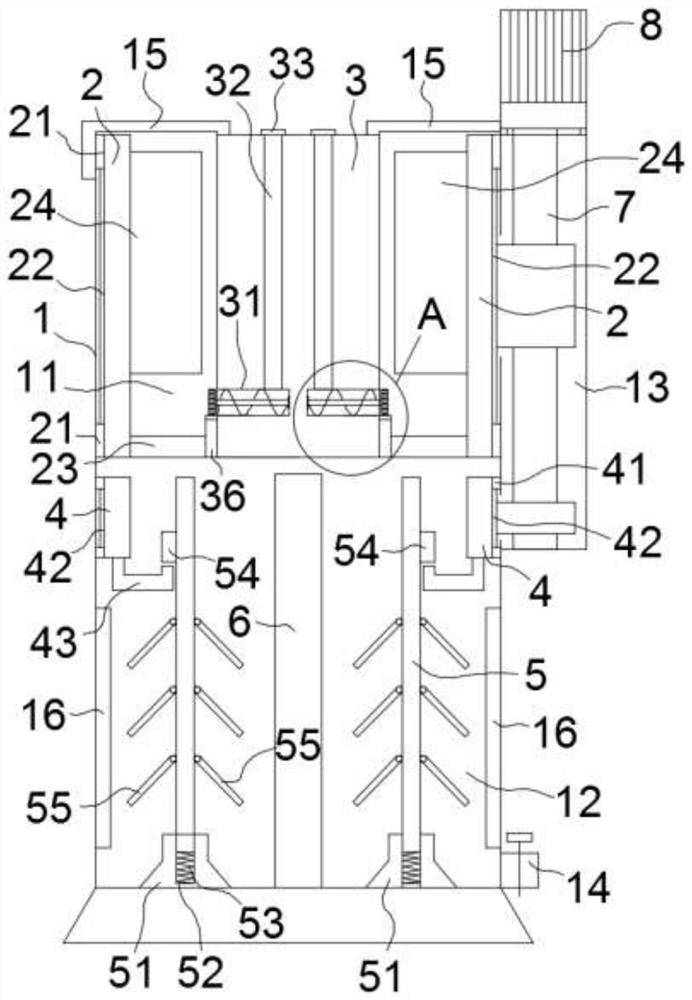

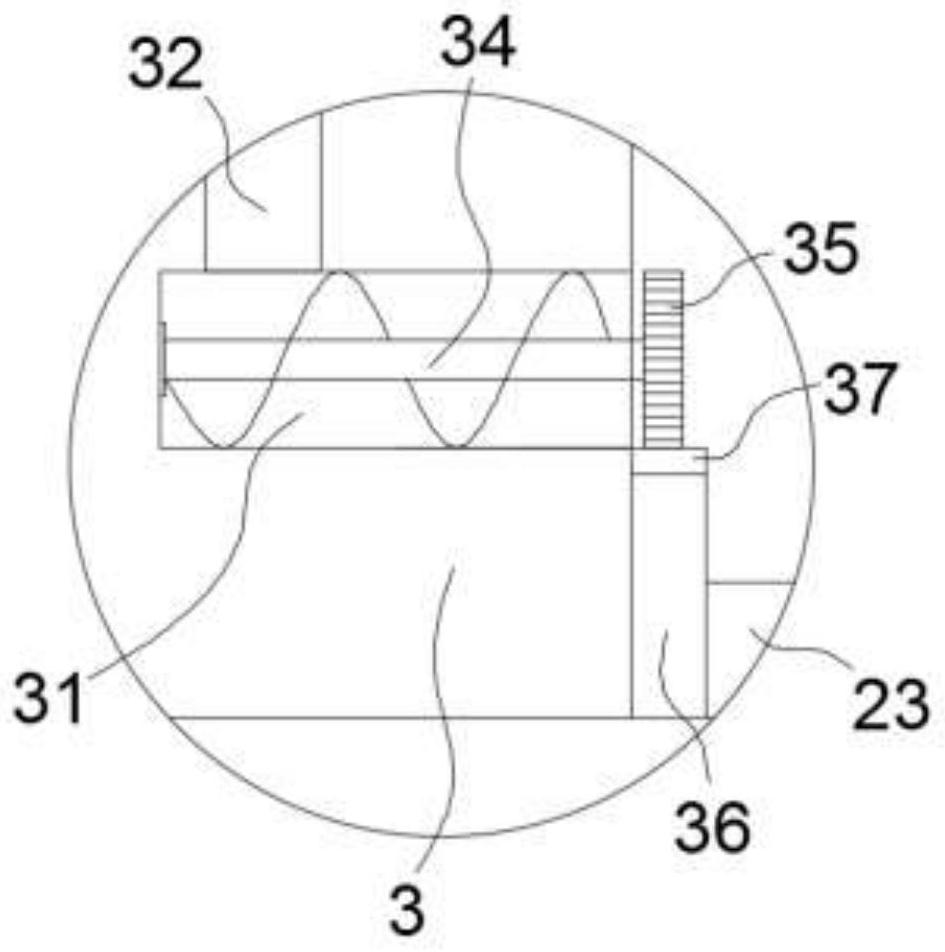

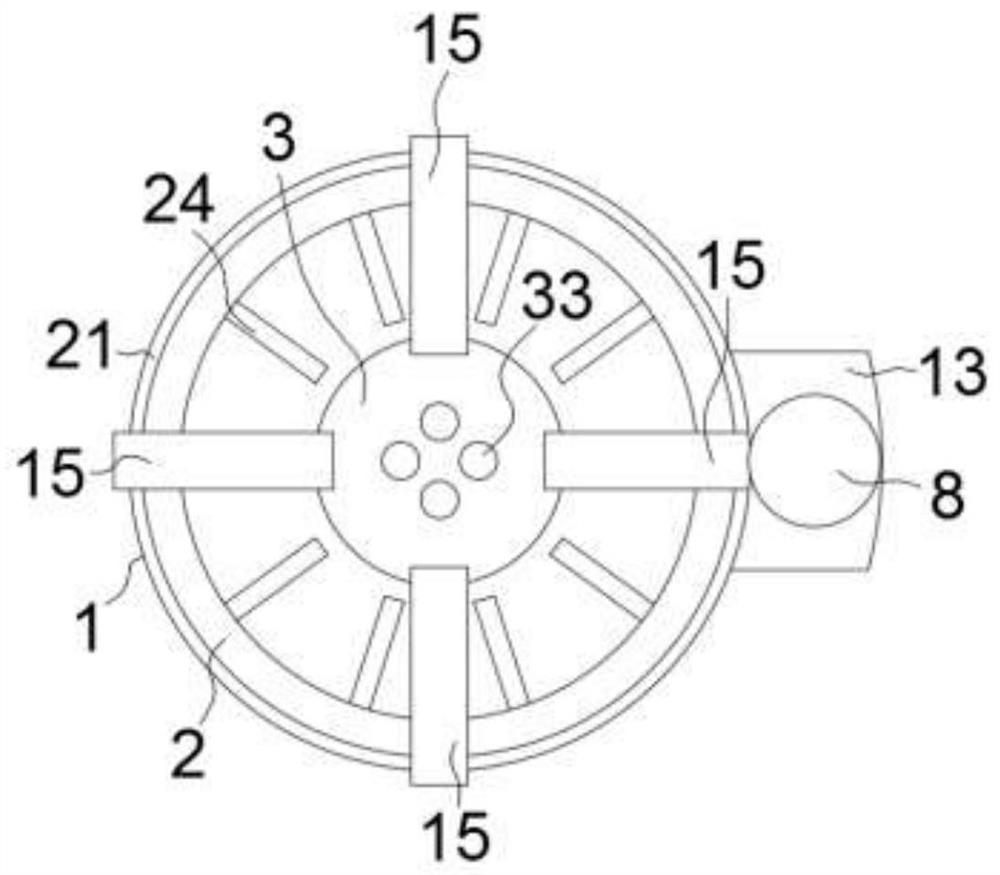

Image

Examples

Embodiment 1

[0037] A water-based wax remover for oil wells, consisting of the following components by weight percentage: 18% mixed surfactant, 2% composite dispersant, 9% alcohol ether co-solvent, 0.5% hydroxyethylene diphosphonic acid, 0.3 % disodium hydrogen phosphate, 0.3% sodium hexametaphosphate, 1% stabilizer, and the rest is composite magnetized water;

[0038] Among them, the mixed surfactant is composed of sodium oleoyloxyethanesulfonate, carbon fatty alcohol polyoxyethylene ether, octylphenol polyoxyethylene ether, and glycerol in a mass ratio of 4:2:1:1. The mixed surfactant prepared by the above ratio can greatly improve the wax removal and anti-wax effect. Mixing, the components of the mixed surfactant are stable and uniform, which is significantly better than that of a single surfactant. The combination of sodium oleoyloxyethanesulfonate, carbon fatty alcohol polyoxyethylene ether, and octylphenol polyoxyethylene ether can reduce each other. Loss in wax removal and anti-wax...

Embodiment 2

[0049] A water-based wax remover for oil wells, consisting of the following components by weight percentage: 21% mixed surfactant, 4% composite dispersant, 11% alcohol ether co-solvent, 1.2% hydroxyethylene diphosphonic acid, 0.4 % disodium hydrogen phosphate, 0.4% sodium hexametaphosphate, 2% stabilizer, and the balance is composite magnetized water;

[0050] Among them, the mixed surfactant is composed of sodium oleoyloxyethanesulfonate, carbon fatty alcohol polyoxyethylene ether, octylphenol polyoxyethylene ether, and glycerol in a mass ratio of 4:2:1:1. The mixed surfactant prepared by the above ratio can greatly improve the wax removal and anti-wax effect. Mixing, the components of the mixed surfactant are stable and uniform, which is significantly better than that of a single surfactant. The combination of sodium oleoyloxyethanesulfonate, carbon fatty alcohol polyoxyethylene ether, and octylphenol polyoxyethylene ether can reduce each other. Loss in wax removal and anti...

Embodiment 3

[0061] A water-based wax remover for oil wells, consisting of the following components by weight percentage: 25% mixed surfactant, 7% composite dispersant, 12% alcohol ether co-solvent, 1.5% hydroxyethylene diphosphonic acid, 0.5% % disodium hydrogen phosphate, 0.5% sodium hexametaphosphate, 3% stabilizer, and the balance is composite magnetized water;

[0062] Among them, the mixed surfactant is composed of sodium oleoyloxyethanesulfonate, carbon fatty alcohol polyoxyethylene ether, octylphenol polyoxyethylene ether, and glycerol in a mass ratio of 4:2:1:1. The mixed surfactant prepared by the above ratio can greatly improve the wax removal and anti-wax effect. Mixing, the components of the mixed surfactant are stable and uniform, which is significantly better than that of a single surfactant. The combination of sodium oleoyloxyethanesulfonate, carbon fatty alcohol polyoxyethylene ether, and octylphenol polyoxyethylene ether can reduce each other. Loss in wax removal and ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com