Care solution for rigid gas permeable contact lenses and preparation method of care solution.

A technology of corneal contact lens and care solution, applied in the field of care solution, which can solve the problems of lens silicide damage, impact on lens life, lens deformation, etc., and achieve the effects of preventing inflammation, reducing friction and increasing lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

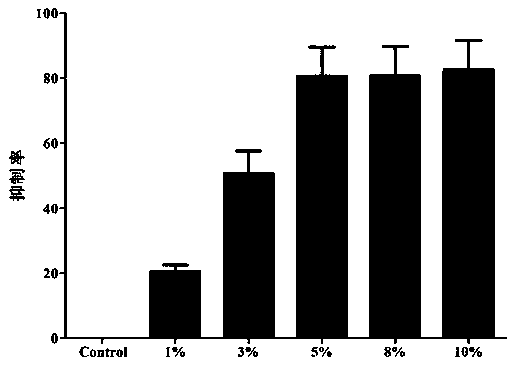

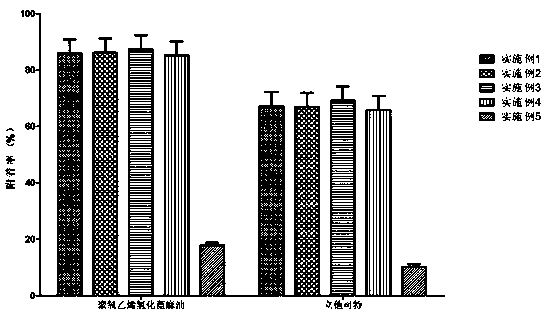

Examples

Embodiment 1

[0027] The preparation material ratio of the silica nano-sol of the present embodiment is as follows: 1.5 parts of ammoniacal liquor; 20 parts of ethyl orthosilicate; 0.5 part of fluorosurfactant; 78 parts of ethanol; 3 parts of propylene glycol, 6 parts of glycerol; Divide the ethanol into two even parts, mix them with tetraethyl orthosilicate and ammonia water respectively, and after magnetic stirring for 10 min, gradually drop the alcohol solution of ammonia water into the alcohol solution of tetraethyl orthosilicate, and stir while dripping (5 min). Raise the temperature to 60°C and use an ultrasonic oscillator with a power of 1200W and a frequency of 60KHz. During the oscillation process, propylene glycol and glycerol are slowly added dropwise. After ultrasonic oscillation for 20 minutes, stir for 2 hours. After adding the fluorosurfactant into the reaction system, it is fully stirred and mixed evenly to obtain the silicon dioxide nano sol. Pour low-pressure pure inert ga...

Embodiment 2

[0032] The preparation material ratio of silica nano sol is as follows: 1 part of ammonia water, 20.9 parts of tetraethyl orthosilicate, 0.1 part of fluorosurfactant, 78 parts of ethanol, 4 parts of propylene glycol, and 5 parts of glycerol;

[0033] Divide the ethanol into two even parts, mix them with tetraethyl orthosilicate and ammonia water respectively, and after magnetic stirring for 10 minutes, gradually drop the alcohol solution of ammonia water into the alcohol solution of tetraethyl orthosilicate, and stir while dripping (5min) . Raise the temperature to 60°C and use an ultrasonic oscillator with a power of 1200W and a frequency of 60KHz. During the oscillation process, propylene glycol and glycerol are slowly added dropwise. After ultrasonic oscillation for 20 minutes, stir for 2 hours. After adding fluorosurfactant to the reaction system, stir and mix well to obtain silica nano-sol; pour low-pressure pure inert gas into the high-vacuum chamber, place sodium chlori...

Embodiment 3

[0039] The preparation material ratio of silica nano sol is as follows: 1.8% ammonia water; 22% tetraethyl orthosilicate; 0.09% fluorosurfactant; 77.73% ethanol; 7 parts of propylene glycol, 4 parts of glycerol;

[0040] Divide the ethanol into two even parts, mix them with tetraethyl orthosilicate and ammonia water respectively, and after magnetic stirring for 10 minutes, gradually drop the alcohol solution of ammonia water into the alcohol solution of tetraethyl orthosilicate, and stir while dripping (5min) . Raise the temperature to 60°C and use an ultrasonic oscillator with a power of 1200W and a frequency of 60KHz. During the oscillation process, propylene glycol and glycerol are slowly added dropwise. After ultrasonic oscillation for 20 minutes, stir for 2 hours. After adding fluorosurfactant to the reaction system, stir and mix well to obtain silica nano-sol; pour low-pressure pure inert gas into the high-vacuum chamber, place sodium chloride particles in a high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com