Dam anti-seepage and water-tight structure

A water-stopping and anti-winding technology, which is applied in water conservancy projects, sea area engineering, construction, etc., can solve the problems of water-stopping and leakage around transverse joints, and achieve the effect of improving the anti-seepage performance and having a targeted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

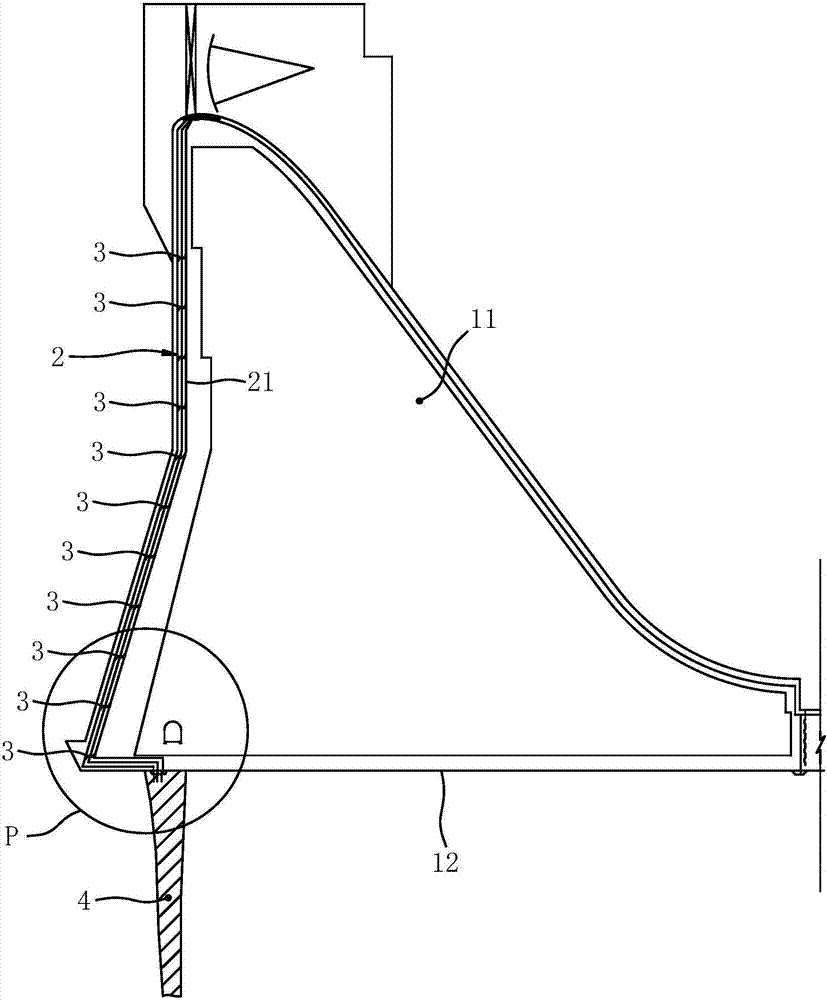

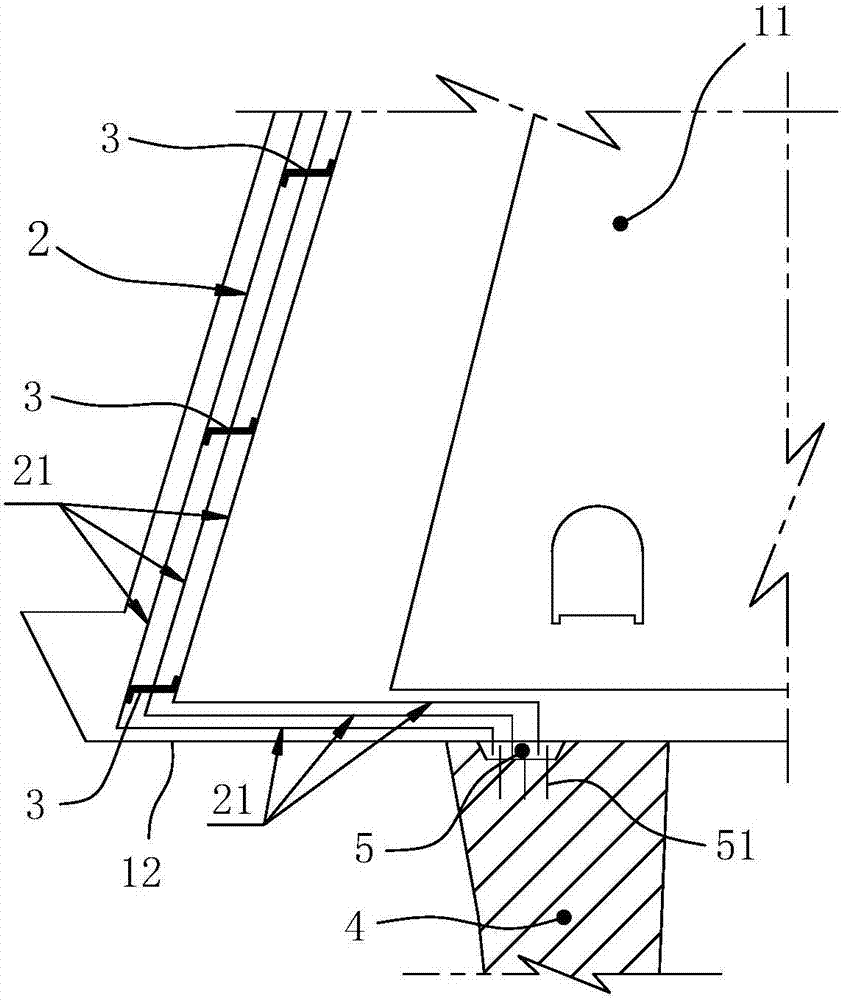

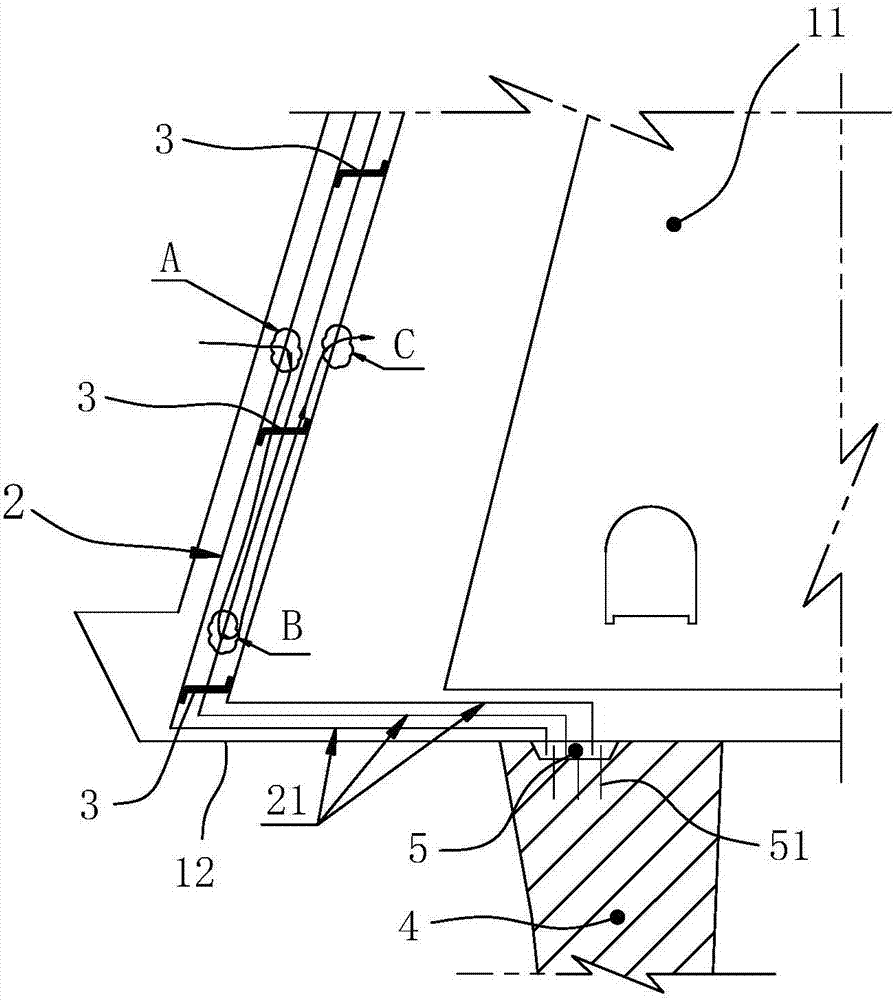

[0020] Such as figure 1 As shown, the dam anti-seepage and water-stop structure includes seam-wise water-stop parts 2 arranged at the transverse joints between the dam body sections 11, and the seam-wise water-stop parts 2 are provided with at least one separate water-stop part 3. Among them, the partition water stop 3 can divide the seam water stop 2 into multiple water stop sections, thereby avoiding seepage around, and facilitates detection and timely and efficient finding of leakage locations; the partition water stop 3 can be tilted Or set it horizontally, subject to the ability to cut off the seam water stop 2; usually, in order to facilitate later leakage monitoring and reduce the monitoring workload, 2 to 5 roads are installed on the seam water stop 2 within every 100m elevation range of the dam Divide the water stop part 3; when there are more than two separate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com