Preparation method of antioxidant tris(2,4-di-tert-butylbenzene) phosphite

A technology of di-tert-butylbenzene and di-tert-butylphenol, which is applied in the field of antioxidant preparation, can solve the problems of low product purity, achieve simple distillation recovery, increase yield, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

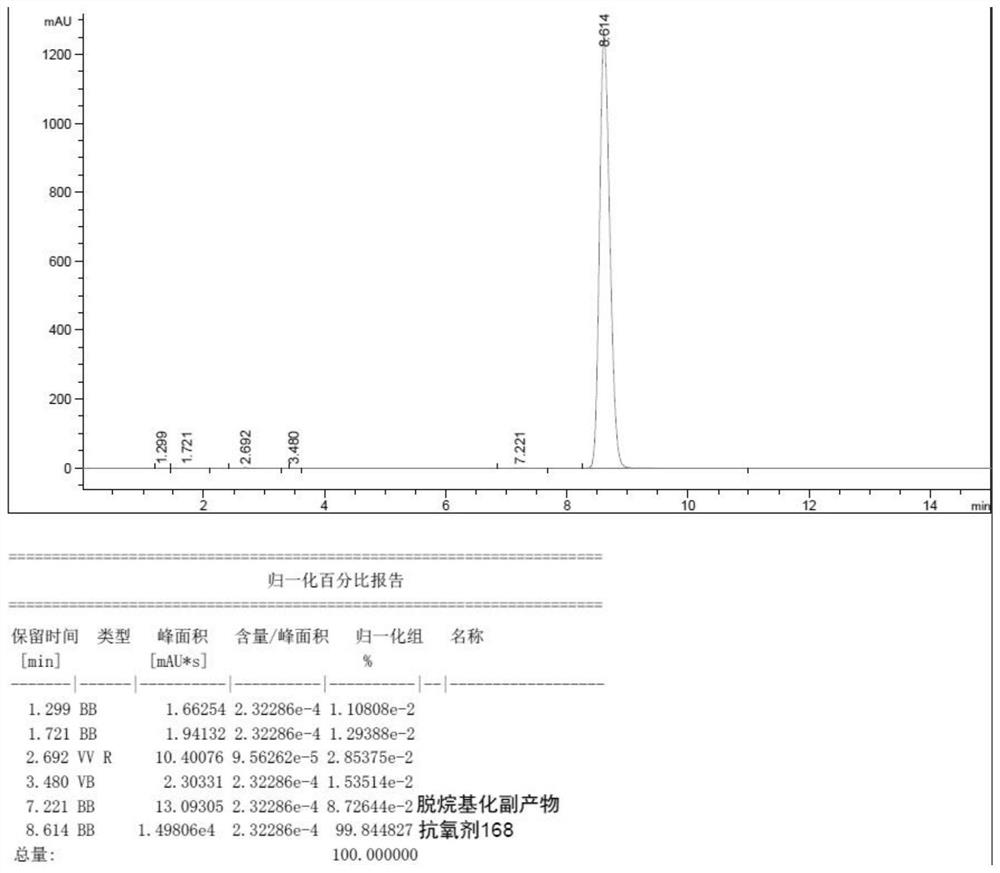

[0052] A preparation method of a phosphite antioxidant, further comprising, after the reaction is finished, crystallizing the reaction liquid to obtain purified antioxidant tris(2,4-di-tert-butylphenyl) phosphite; crystallization filtrate After distilling off the crystallization solvent, 2,4-di-tert-butylphenol was recovered and used mechanically. The product obtained by the above preparation method of the present invention can be recycled and utilized after the crystallization solvent is removed by simple distillation. The impact on product quality (mainly purity, acid value and hydrolysis resistance) caused by high-temperature and high-pressure distillation recovery of 2,4-di-tert-butylphenol is avoided.

[0053] The crystallization solvent is a mixed system of lower aliphatic alcohol and reaction solvent, and the lower aliphatic alcohol refers to C 1 -C 8 Alcohol, such as: methanol, ethanol, propanol, isopropanol, etc., the reaction solvent is the remaining solvent in the...

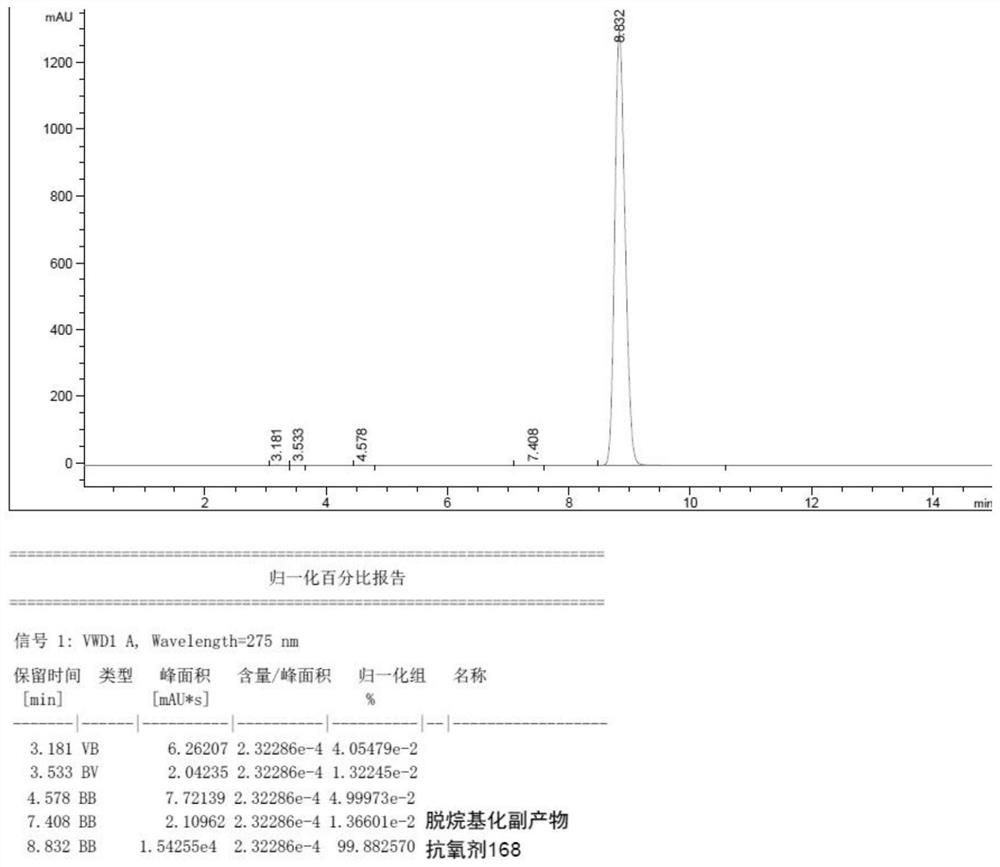

Embodiment 1

[0059] The preparation of embodiment 1 antioxidant 168

[0060] (1) Synthesis reaction: Add 133.0g (0.646mol) of 2,4-di-tert-butylphenol, 200mL of xylene, and 2.29g (0.0226mol) of catalyst triethylamine into a 1000mL four-necked flask, stir and heat up to 50~ 55°C; then start to add 29.6g (0.216mol) of phosphorus trichloride dropwise, control the temperature in the kettle at 50-55°C during the dropwise addition, finish dropping after 3.5h, keep stirring for 1hr after adding dropwise; then slowly raise the temperature to 140-145°C ℃, heat preservation reaction for 4 hours, when there is basically no HCl gas generated in the system, increase the reaction temperature to 145-155 ℃, insert a nitrogen tube, continuously feed nitrogen from the bottom of the four-necked bottle, and use a water pump to control the slight negative pressure of the system at 96-100Kpa, Continue to react for 5 hours, take a sample to detect that the pH value of the reaction solution is 4, and stop the reac...

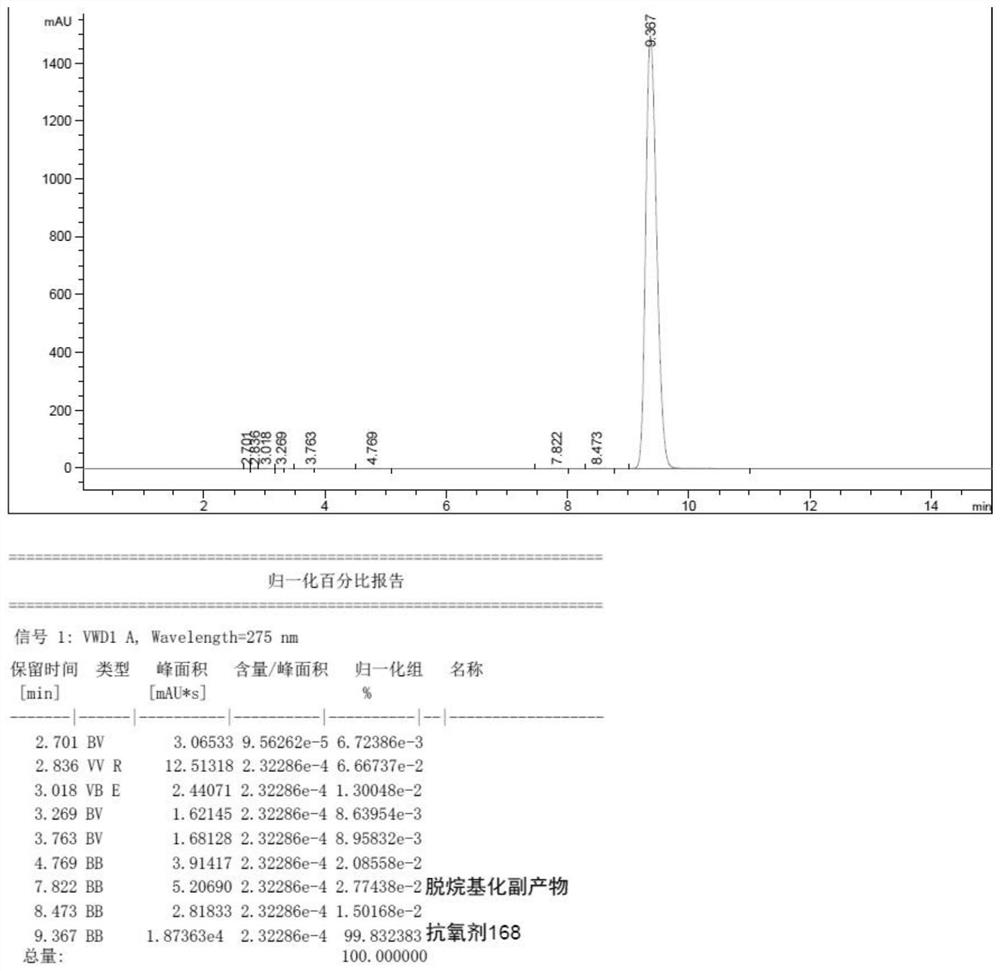

Embodiment 2

[0062] Example 2 Crystallization Mother Liquor Recovery and Application to Prepare Antioxidant 168

[0063] Crystallization mother liquor treatment: distill the crystallization mother liquor in Example 1 to a liquid phase temperature above 145° C., stop distillation, and keep the still liquid for use.

[0064] (1) Synthetic reaction: the crystallization kettle liquid obtained in Example 1, 133.0g (0.646mol) 2,4-di-tert-butylphenol, 50mL toluene, 2.85g (0.0154mol) catalyst tri-n-butylamine were added to 1000mL In the four-necked bottle, stir and heat up to 80-85°C; then start to drop 29.6g (0.216mol) of phosphorus trichloride, and control the temperature in the kettle to 80-85°C during the dropping process, and finish dropping in 3.5 hours. Stir for 1 hour; then slowly raise the temperature to 120-125°C, and keep the temperature for 3 hours. When there is basically no HCl gas in the system, increase the reaction temperature to 145-155°C, insert a nitrogen tube, and continuously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com