Preparation method of N-(phosphonomethyl)iminodiacetic acid

A technology of bisglyphosate and ammonium chloride, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, ammonium halide, etc., can solve problems such as cost, safety, environmental protection and high energy consumption, and save equipment investment , Realize the utilization of resources and solve the effect of environmental protection treatment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

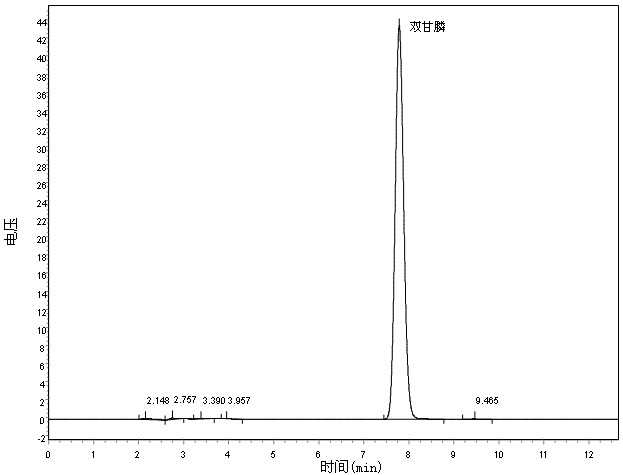

Image

Examples

Embodiment 1

[0015] Put 100g (1mol) of iminodiacetonitrile and 180g of water into a reaction flask with stirring, raise the temperature to 40°C, and evenly add 138.9g (1mol) of phosphorus trichloride dropwise for acidolysis reaction. After the dropwise addition, raise the temperature to 80°C, keep warm for 4 hours. Add 81.1g mass fraction of 37% formaldehyde (1mol) at 90°C and keep it warm for 5 hours to generate diglyphosate, cool down to 10°C, crystallize, separate solid and liquid, wash with water, and dry to obtain a mass fraction of 98.1% bisglyphosate The product is 199g, the yield is 86%; the reaction mother liquor is 702g, and the mass fraction of bisglyphosate is 2.2%.

[0016] Introduce 18g of ammonia gas into 702g of reaction mother liquor, PH=3, heat up and evaporate and dehydrate 270g, ammonium chloride is supersaturated and precipitated, cool and crystallize, and separate solid and liquid to obtain 110g of ammonium chloride, mass fraction 99.3%; concentrate mother liquor 285g...

Embodiment 2

[0018] Put 100g (1mol) of iminodiacetonitrile, 720g of water and 285g of the concentrated mother liquor in Example 1 into a stirred reaction flask, raise the temperature to 70°C, and evenly drop 277.8g (2mol) of phosphorus trichloride to carry out the acidolysis reaction , after the dropwise addition was completed, the temperature was raised to 130° C., and the temperature was kept for 1 hour. Add 162.2g of 37% formaldehyde (2mol) at 120°C and keep it warm for 2 hours to generate diglyphosate, cool down to 10°C, crystallize, and separate the solid and liquid to obtain 208.1g of diglyphosate with a mass fraction of 98.2%. The yield is 90%; the reaction mother liquor is 1298g, and the mass fraction of bis-glyphosate is 3.9%.

[0019] Introduce 105g of ammonia gas into 1298g of reaction mother liquor, PH=7, heat up to evaporate and dehydrate 700g, cool and crystallize, and separate solid and liquid to obtain 300g of ammonium chloride, with a mass fraction of 99.0%; 360g of concen...

Embodiment 3

[0021] Put 100g (1mol) of iminodiacetonitrile and 540g of water into a reaction flask with stirring, raise the temperature to 50°C, and evenly add 187.5g (1.35mol) of phosphorus trichloride dropwise for acidolysis reaction. After the dropwise addition, raise the temperature to 100°C for 2 hours. Add 121.6g mass fraction of 37% formaldehyde (1.5mol) at 100°C, keep warm for 3 hours to generate bisglyphosate, deacidify water 300g, add water 300g, cool down to 15°C, crystallize, solid-liquid separation to obtain a mass fraction of 98.5 207.5g of bis-glyphosate product, the yield is 90%; the reaction mother liquor is 742g, and the mass fraction of bis-glyphosate is 2.6%.

[0022] Introduce 29g of ammonia gas into 742g of reaction mother liquor, pH=5.5, heat up to evaporate and dehydrate 378g, cool and crystallize, and separate solid and liquid to obtain 123g of ammonium chloride, with a mass fraction of 99.2%; 252g of concentrated mother liquor will be used until the next batch of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com