Method for producing technical-grade fosetyl-aluminum

A technology of triethylphosphine and aluminum acid, applied in the field of producing fungicide technical, can solve the problems of poor on-site environment, long reaction time, difficult operation, etc., achieve fast reaction speed, improve reaction yield and content, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

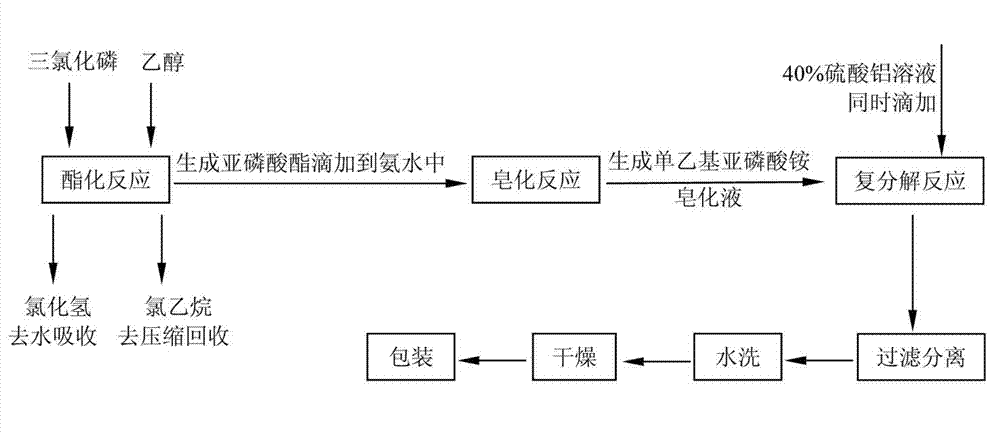

Method used

Image

Examples

Embodiment 1

[0030] Phosphorus trichloride and ethanol are continuously mixed for esterification. The specific steps are: use the canned pump to make 600Kg 99% phosphorus trichloride and 600Kg 90% ethanol pass through the static mixing reactor (SV3.5 / 32) for continuous mixing at a speed of 600Kg / hour through the flowmeter, and then enter the esterification process. Still, the esterification temperature is 50-60°C, the vacuum degree is 0.08MPa-0.09 MPa, and 680Kg of phosphite is generated, wherein the content of phosphite is about 85% by mass percentage, and by-products hydrogen chloride and ethyl chloride are produced at the same time. Hydrogen chloride is absorbed by water, and ethyl chloride is compressed and recovered.

[0031] According to the above steps, the results of three parallel reactions of absolute ethanol and ethanol with a concentration of 90% are shown in Table 1.

[0032] Table 1 Experimental results of different concentrations of ethanol reaction

[0033] ba...

Embodiment 2

[0036] The feed liquid generated in Example 1 is continuously saponified with an inorganic base, and the inorganic base may be an aqueous ammonia solution. The specific steps are: add 800L of ammonia water with a mass percentage of 10% to a 3000L glass-lined airfoil stirred reactor, stir, turn on the cooling water to cool down, and wait for the temperature in the reactor to drop to 5°C, and start to continuously drop in Example 1 to obtain The phosphite feed liquid is subjected to saponification reaction. During the dropping process, the temperature is kept not exceeding 45°C, and the dropping time is 3-4 hours. ammonium phosphate solution. In this embodiment, three groups of parallel experiments were carried out by using the forward dripping and reverse dripping methods of phosphite in the ammonia solution, and the results are shown in Table 2, wherein, the forward dripping refers to the dripping of ammonia water into the phosphite solution. Adding, back-dropping refers to t...

Embodiment 3

[0041] First add 750Kg water in the preparation kettle, stir, add 50Kg solid aluminum sulfate simultaneously, stir and dissolve 0.5 hour, be mixed with 40% aluminum sulfate solution, pour into metering tank, the saponified monoethyl liquid phosphorous acid obtained in Example 2 Ammonium is poured into another metering tank, and the feed valves of the aluminum sulfate solution and ammonium phosphite solution metering tank are opened at the same time, and they are continuously fed into the metathesis reactor for reaction. The ammonium solution flow rate is 1,420Kg / hour. The reaction temperature is 80-85°C, and the aluminum triethylphosphonate slurry is generated immediately after the reaction. The slurry is continuously filtered and separated by a vacuum horizontal belt filter (filter cloth 300 mesh), and then continuously processed with water at a flow rate of 100Kg / hour. Washed with water, and finally sent to the XSG spin flash dryer continuously through the wet material conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com