High-temperature diesel antioxidant and preparation method thereof

An antioxidant and diesel oil technology, applied in the field of diesel additives, can solve the problems of high toxicity, low efficiency, and poor compatibility of diesel oil, etc., and achieve the effects of improved antiknock performance, broad application prospects, and low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

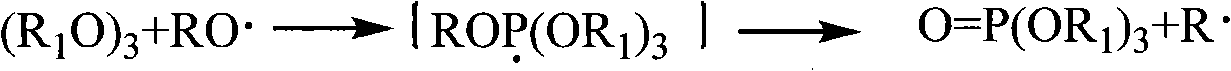

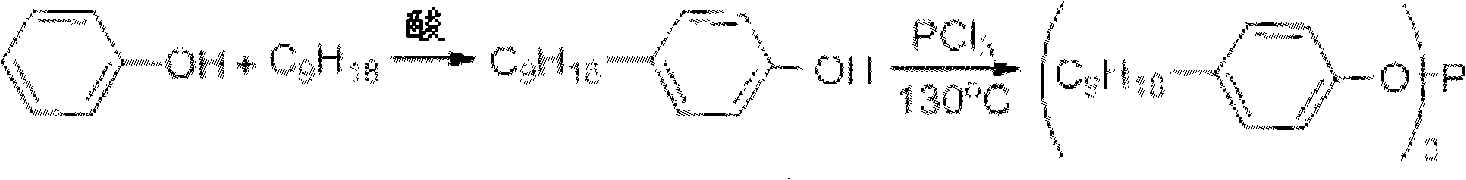

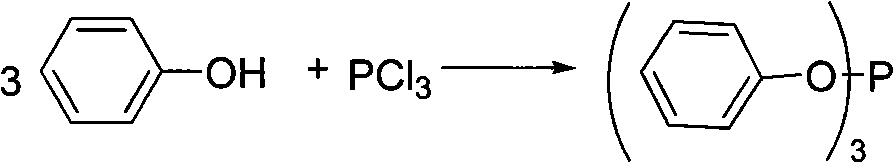

Method used

Image

Examples

Embodiment 1

[0036] Add pentaerythritol, toluene, and tetramethylammonium chloride respectively in a four-neck flask equipped with a thermometer, dropping funnel, and reflux condenser, wherein the quality of toluene is 100% of that of pentaerythritol, and the quality of tetramethylammonium chloride is the amount of pentaerythritol. 2%, set the stirring speed to be 200 rev / min, add dropwise phosphorus trichloride, its molar weight is 4 times of pentaerythritol, dropwise time is 0.5 hour, control temperature at 80 ℃, absorb the hydrogen chloride gas that generates with tail gas absorption bottle , react until no hydrogen chloride gas is generated, and the intermediate dichloropentaerythritol bisphosphite is obtained. The dichloropentaerythritol bisphosphite that generates is transferred to the dropping funnel together with the solvent, and in the four-necked flask, add dodecanol, which is 2 times of the dichloropentaerythritol bisphosphite molar weight, drips into dichloropentaerythritol bisp...

Embodiment 2

[0038] Pentaerythritol, toluene, and tetramethylammonium chloride were metered into a four-necked flask equipped with a thermometer, dropping funnel, and reflux condenser, wherein the quality of toluene was 100% of that of pentaerythritol, and the quality of tetramethylammonium chloride was 100% of that of pentaerythritol. 2% of the amount, set the stirring speed to 200 rpm, dropwise add phosphorus trichloride whose molar weight is 4 times that of pentaerythritol, dropwise time is 0.5 hour, control the temperature at 80 ° C, absorb the generated hydrogen chloride with the tail gas absorption bottle gas, and react until no hydrogen chloride gas is generated to obtain the intermediate dichloropentaerythritol bisphosphite. The generated dichloropentaerythritol bisphosphite is transferred to the dropping funnel together with the solvent, and tetradecyl alcohol is added in a four-neck flask, which is 2 times the molar weight of dichloropentaerythritol bisphosphite. For the pentaery...

Embodiment 3

[0040]Pentaerythritol, toluene, and tetramethylammonium chloride were metered into a four-necked flask equipped with a thermometer, dropping funnel, and reflux condenser respectively. 2% of the amount, set the stirring speed to 200 rpm, dropwise add phosphorus trichloride whose molar weight is 4 times that of pentaerythritol, dropwise time is 0.5 hour, control the temperature at 80 ° C, absorb the generated hydrogen chloride with the tail gas absorption bottle gas, and react until no hydrogen chloride gas is generated to obtain the intermediate dichloropentaerythritol bisphosphite. The dichloropentaerythritol bisphosphite that will generate is transferred to the dropping funnel together with the solvent, and it is 2 times of the dichloropentaerythritol bisphosphite molar weight in the four-necked flask, and dichloro The pentaerythritol bisphosphite solution is added dropwise for 0.5 hours, and the temperature is controlled at 30°C. After the reaction, the solvent was distille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com